- Home

- Machining

- Drilling Holemaking

- Drill Bits

- Drill Bits For Metal Plastic

.....Read More

Annular Cutters

Carbide-Tipped Jobber-Length Drill Bits

Carbide-Tipped Screw-Machine Length Drill Bits

Cobalt Extended-Length Drill Bits

Cobalt Jobber-Length Drill Bits

Cobalt Screw-Machine Length Drill Bits

Coolant-Through High-Speed Steel Jobber-Length Drill Bits

Coolant-Through Solid Carbide Jobber-Length Drill Bits

Double-Ended Drill Bits

Double-Margin Drill Bits

Drill Reamers for Composites

Flat-Bottom Drill Bits

Hex-Shank Drill Bits

Hex-Shank Drill Bit Sets

High-Speed Steel Extended-Length Drill Bits

High-Speed Steel Screw-Machine Length Drill Bits

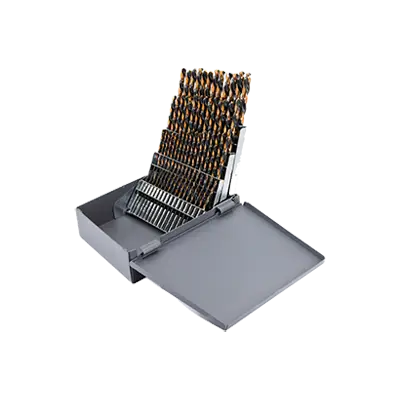

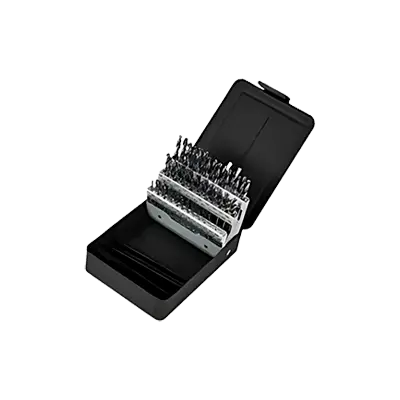

Jobber-Length Drill Bit Sets

Left-Hand Non-Coolant-Through High-Speed Steel Jobber-Length Drill Bits

Mechanics-Length Drill Bits

Mechanics-Length Drill Bit Sets

Metalworking Micro Drill Bits

Micro Drill Bits for Circuit Boards

NAS-Spec Non-Coolant-Through High-Speed Steel Jobber-Length Drill Bits for Aerospace

Non-Coolant-Through High-Speed Steel Jobber-Length Drill Bits

Non-Coolant-Through Solid Carbide Jobber-Length Drill Bits

Powdered-Metal Jobber-Length Drill Bits

Powdered-Metal Screw-Machine Length Drill Bits

Reduced-Shank Drill Bits

Reduced-Shank Drill Bit Sets

Screw-Machine-Length Drill Bit Sets

Solid Carbide Extended-Length Drill Bits

Solid Carbide Screw-Machine Length Drill Bits

Solid Spade Drill Bits

Solid Spade Drill Bit Sets

Spot-Weld Drill Bits

Spot-Weld Drill Bit Sets

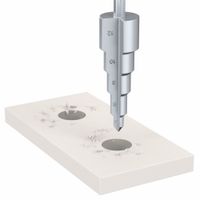

Step Drill Bits

Straight-Flute Drill Bits

Straight-Flute Drill Bit Sets

Taper-Length Drill Bits

Taper-Length Drill Bit Sets

Taper-Shank Drill Bits

Taper-Shank Drill Bit Sets

Thermal Drilling Tools & Toolholders

Threaded-Shank Drill Bits

Vanadium High-Speed Steel Jobber-Length Drill Bits

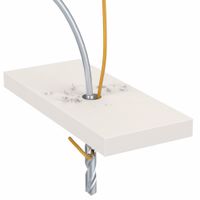

Wire & Cable Installer Drill Bits for Metal & Plastic

Frequently Asked Questions

What are the best drill bits for metal?

How do I choose the right drill bit size?

Can I use metal drill bits on plastic?

What is the difference between HSS and cobalt drill bits?

How do I sharpen drill bits?

What is the best drill speed for metal?

How do I prevent drill bits from overheating?