Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

.....Read More

Frequently Asked Questions

What is machining and how does it work?

Machining is a manufacturing process that removes material from a workpiece to create a desired shape or form. It involves using various tools and techniques, such as cutting, drilling, milling, grinding, and turning. The process typically starts with a raw piece of material, like metal, plastic, or wood. Specialized machines then precisely remove chips or layers of material, following a design or blueprint. This controlled removal of material allows for the creation of intricate parts with high accuracy and tight tolerances, essential for industries ranging from automotive to aerospace.

What are the different types of machining processes?

Machining processes involve removing material from a workpiece to create a desired shape. Common types include:1. Turning: A workpiece rotates against a cutting tool to remove material from the outer diameter or inner bore.

2. Milling: A rotating multi-point cutting tool removes material from a stationary workpiece.

3. Drilling: A rotating drill bit creates a cylindrical hole.

4. Grinding: An abrasive wheel removes small amounts of material for a precise finish.

5. Sawing: A saw blade cuts material.

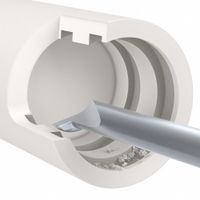

6. Boring: Enlarging an existing hole using a single-point cutting tool.

7. Broaching: Using a multi-tooth tool to create specific shapes.

These processes are fundamental in manufacturing across various industries.

What materials can be used in machining?

Machining is a versatile manufacturing process capable of shaping a wide array of materials. Metals like aluminum, steel, brass, titanium, and various alloys are commonly machined due to their strength and workability. Plastics such as ABS, nylon, polycarbonate, and acrylic are also frequently used, offering lightweight and corrosion-resistant properties. Composites, including carbon fiber and fiberglass, can be machined, though they often require specialized tooling due to their abrasive nature. Even ceramics, despite their hardness, can be machined with appropriate techniques and equipment, typically for precision applications. The choice of material depends heavily on the desired product's application and performance requirements.

What is CNC machining and its advantages?

CNC (Computer Numerical Control) machining is a manufacturing process where computer software dictates the movement of factory tools and machinery. It offers significant advantages over manual machining due to its precision, automation, and efficiency.

Key advantages include: * High Accuracy and Repeatability: Produces identical parts consistently, reducing human error.

* Increased Production Speed: Automated operations lead to faster manufacturing cycles.

* Reduced Labor Costs: Requires less manual intervention, lowering operational expenses.

* Enhanced Safety: Operators are less exposed to dangerous machinery.

* Versatility: Can work with various materials and produce complex geometries.

* Waste Reduction: Optimized tool paths and precise cuts minimize material waste.

How much does machining cost?

Machining costs vary significantly based on several factors. The complexity of the part, the type of material (e.g., aluminum, steel, titanium), and the required tolerances all play a major role. Production volume is another key determinant; higher volumes often lead to lower per-unit costs due to economies of scale. Labor rates for skilled machinists, machine time, tooling expenses, and any post-processing treatments (like heat treating or finishing) also contribute to the overall cost. For an accurate quote, it's best to provide detailed specifications and drawings to a machining service.

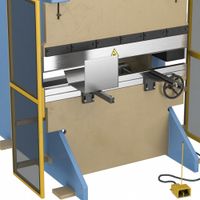

What are the common tools used in machining?

Common machining tools include lathes, milling machines, drill presses, and grinding machines. Lathes are used for turning operations, creating cylindrical parts. Milling machines perform various cuts, from flat surfaces to complex contours, using rotating multi-point cutters. Drill presses create holes with precision. Grinding machines use abrasive wheels for fine finishing and shaping. Other essential tools are saws for cutting stock, boring machines for enlarging existing holes, and specialized tooling like reamers, taps, and dies for specific hole finishing and thread cutting. These tools collectively enable the precise shaping and fabrication of metal and other materials.

What is the difference between milling and turning in machining?

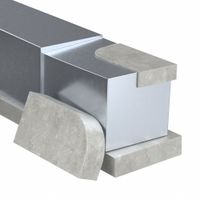

Milling and turning are subtractive manufacturing processes, but they differ in how material is removed. In milling, the workpiece remains stationary while a rotating multi-point cutting tool moves around it to remove material and create a desired shape. This is ideal for producing flat surfaces, slots, and complex geometries.

Conversely, in turning, the workpiece rotates while a stationary single-point cutting tool removes material from its outer diameter or inner bore. This process is commonly used for creating cylindrical parts like shafts, bushings, and screws. The key distinction lies in which component rotates: the tool in milling, and the workpiece in turning.

How to choose the right machining technique for a project?

Choosing the right machining technique depends on several factors, including material type, desired precision, complexity of the part, production volume, and cost. Common techniques include milling, turning, drilling, grinding, and various additive manufacturing (3D printing) methods. For high precision and complex geometries, CNC machining (milling and turning) is often preferred. For mass production of simple parts, traditional methods might be more cost-effective. Additive manufacturing excels in creating intricate designs and prototypes with minimal material waste. Consider the mechanical properties required of the final product and the lead time available. Consulting with an experienced machinist or engineer can help optimize the selection process for your specific project needs.

What are the safety precautions in machining?

Safety in machining is paramount. Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and suitable clothing (no loose items). Ensure machine guards are in place and functioning correctly. Before operation, check that tools are secure and workpieces are properly clamped. Never leave a running machine unattended. Understand and follow lockout/tagout procedures before performing maintenance or clearing jams. Keep the work area clean and free of obstructions to prevent slips and trips. Report any malfunctions or unsafe conditions immediately. Adhering to these precautions minimizes risks and prevents accidents.

How to improve precision and accuracy in machining?

Improving precision and accuracy in machining involves several key strategies. Start with high-quality, well-maintained machinery, ensuring proper calibration and minimal vibration. Use precise tools and fixtures, regularly checking for wear and tear. Material selection is crucial; understand its properties and how it reacts to machining. Optimize cutting parameters like speed, feed rate, and depth of cut to minimize tool deflection and heat buildup. Employ advanced measurement and inspection techniques, such as CMMs and laser micrometers, for continuous feedback and process control. Implement lean manufacturing principles to reduce errors and waste. Operator training and experience also play a significant role in achieving consistent, high-quality results.