Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

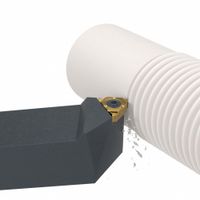

What are indexable cutting tools?

Indexable cutting tools are advanced machining tools that feature replaceable cutting inserts, allowing for quick and easy tool changes without removing the entire tool from the machine. These inserts are typically made from hardened materials like carbide, ceramic, or cubic boron nitride (CBN), offering superior wear resistance and high-temperature performance.

The primary advantage of indexable tools lies in their efficiency and cost-effectiveness. When an insert wears out or breaks, it can be easily indexed (rotated to a fresh cutting edge) or replaced, eliminating the need to resharpen or scrap the entire tool body. This significantly reduces downtime, increases productivity, and lowers tooling costs in manufacturing operations.

Indexable cutting tools are widely used in various machining processes, including turning, milling, drilling, and threading. They are designed with precise geometries and chipbreakers to optimize chip evacuation and surface finish. The modular design of these tools also allows for greater flexibility in selecting appropriate inserts for different materials and applications, making them indispensable in modern metalworking industries.

How do indexable cutting tools differ from traditional cutting tools?

Indexable cutting tools differ from traditional cutting tools primarily in their design, maintenance, and economic implications. Traditional cutting tools, often made from a single piece of high-speed steel (HSS) or carbide, require periodic resharpening when they become dull. This resharpening process can be time-consuming, requires specialized equipment, and gradually reduces the tool's overall size and lifespan. Once the tool becomes too small to be effective or can no longer be resharpened, it is discarded.

In contrast, indexable cutting tools consist of a tool holder and replaceable, multi-sided inserts. These inserts are typically made from cemented carbide or other advanced materials and feature multiple cutting edges. When one cutting edge becomes dull, the insert can be "indexed," or rotated, to present a fresh cutting edge. Once all edges on an insert are dull, the insert is simply replaced with a new one. This eliminates the need for resharpening, significantly reducing downtime and maintenance costs.

The key differences can be summarized as:1. **Maintenance:** Traditional tools require resharpening; indexable tools use replaceable inserts.

2. **Downtime:** Resharpening leads to more downtime; replacing inserts is quick.

3. **Cost-Effectiveness:** While inserts might have a higher initial cost per piece, the reduced labor for resharpening, increased productivity, and consistent performance often make indexable tools more cost-effective in the long run, especially for high-volume production.

4. **Consistency:** New inserts offer consistent geometry and performance, whereas resharpened traditional tools can have slight variations.

5. **Material:** Traditional tools are often solid HSS or carbide; indexable inserts can utilize a wider range of specialized materials and coatings for specific applications.Overall, indexable cutting tools offer increased efficiency, productivity, and reduced operational costs in many modern manufacturing environments due to their modular design and easy insert replacement.

What are the advantages of using indexable cutting tools?

Indexable cutting tools offer numerous advantages over traditional brazed or solid carbide tools, making them a popular choice in modern machining operations. One of the primary benefits is their cost-effectiveness. Instead of discarding an entire tool when the cutting edge wears, only the insert needs to be replaced. This significantly reduces tooling costs and downtime associated with resharpening.

Furthermore, indexable inserts are available in a wide range of geometries, grades, and coatings, allowing for optimized performance across various materials and machining conditions. This versatility enables shops to use the same tool holder for different applications simply by changing the insert, leading to reduced inventory and increased flexibility.

The precision and repeatability of indexable inserts also contribute to improved part quality. Each new insert provides a consistent and sharp cutting edge, ensuring uniform surface finishes and tight tolerances. This consistency is crucial for high-volume production and complex machining tasks.

Another key advantage is the ease of tool changes. Replacing an insert is a quick and straightforward process that can often be done directly at the machine, minimizing setup times and maximizing machine utilization. This "plug-and-play" nature enhances productivity and streamlines operations.

In summary, the advantages of indexable cutting tools—including cost savings, versatility, precision, and ease of use—make them an indispensable asset in achieving efficient and high-quality machining results.

How do you choose the right indexable insert for a specific application?

Choosing the right indexable insert involves considering several factors to optimize performance and tool life for a specific application.

First, identify the material being machined. Different materials (e.g., steel, stainless steel, cast iron, aluminum, superalloys) require specific carbide grades and coatings for optimal wear resistance and toughness. For example, a harder, more wear-resistant grade might be suitable for abrasive materials, while a tougher grade might be better for interrupted cuts.

Second, consider the type of machining operation. Turning, milling, and drilling each have unique demands on the insert. For turning, factors like continuous or interrupted cut, roughing or finishing, and chip control are important. For milling, the type of milling (face, shoulder, slot) and the machine's stability play a role.

Third, assess the chip control requirements. The insert's chip breaker geometry is crucial for forming manageable chips, preventing chip packing, and ensuring smooth evacuation. Different chip breakers are designed for various feed rates, depths of cut, and materials.

Fourth, evaluate the machine tool's condition and power. A stable machine with sufficient power can handle more aggressive inserts and cutting parameters, while older or less rigid machines might require inserts with positive rake angles and lighter cutting forces.

Fifth, consider the desired surface finish and dimensional tolerances. Finishing operations typically require inserts with smaller nose radii and sharper cutting edges to achieve a smooth surface, while roughing prioritizes material removal rate.

Finally, factor in cost-effectiveness. While high-performance inserts may have a higher initial cost, their increased productivity and longer tool life can lead to lower overall manufacturing costs. It's essential to balance performance with economic considerations for the specific application.

What materials are indexable inserts typically made from?

Indexable inserts are typically made from a variety of hard, wear-resistant materials, each suited for different machining applications. The most common material is cemented carbide, a composite material primarily composed of tungsten carbide particles bonded together by a metallic binder, usually cobalt. Carbide inserts offer excellent hardness and wear resistance at high temperatures, making them ideal for machining a wide range of materials from steel to superalloys.

Beyond cemented carbide, other materials are used for specialized applications. Ceramic inserts, made from materials like aluminum oxide or silicon nitride, are extremely hard and chemically stable, making them suitable for high-speed machining of cast iron, hardened steel, and superalloys where heat generation is significant. Polycrystalline cubic boron nitride (PCBN) inserts are even harder than ceramics and are used for machining very hard materials like hardened steels, chilled cast iron, and high-temperature alloys at very high cutting speeds. Polycrystalline diamond (PCD) inserts, the hardest of all cutting tool materials, are used for machining non-ferrous materials like aluminum, copper, and composites, as well as highly abrasive materials, where their extreme hardness and low friction are advantageous.

How do you maintain and care for indexable cutting tools?

Maintaining and caring for indexable cutting tools is crucial for maximizing their lifespan, ensuring consistent performance, and achieving high-quality results. Proper maintenance involves several key practices.

Firstly, regular cleaning is essential. After each use, remove chips, coolant residue, and any other debris from the tool body and insert pockets. A soft brush, compressed air, or a suitable cleaning solution can be used, but avoid harsh chemicals that could damage the tool's coating or material.

Secondly, inspect the inserts for wear, chipping, or damage. Worn inserts lead to poor surface finish, increased cutting forces, and reduced tool life. If an insert shows signs of wear, indexing it to a fresh cutting edge or replacing it entirely is necessary. Always follow the manufacturer's recommendations for indexing or replacement.

Thirdly, proper storage is vital. Store indexable cutting tools in their original packaging or in dedicated tool holders that protect them from impact, moisture, and contaminants. This prevents damage to the inserts and the tool body, ensuring they are in optimal condition for future use.

Finally, adhere to correct operational practices. This includes using the appropriate cutting parameters (speed, feed, depth of cut) for the material being machined, ensuring proper chip evacuation, and using suitable coolant if necessary. Overloading the tool or using incorrect parameters can accelerate wear and lead to premature tool failure. By consistently implementing these care and maintenance practices, you can significantly extend the life and efficiency of your indexable cutting tools.

What are the common applications of indexable cutting tools?

Indexable cutting tools are widely used in various machining operations due to their versatility, efficiency, and cost-effectiveness. Their primary advantage lies in the ability to replace worn or damaged inserts without having to replace the entire tool body, leading to reduced downtime and tooling costs.

Common applications include: * **Milling:** Indexable end mills and face mills are used for a wide range of milling operations, from roughing to finishing, on various materials like steel, aluminum, and cast iron. They are particularly effective for high material removal rates.

* **Turning:** Indexable turning inserts are essential for external and internal turning operations on lathes. They come in various geometries and grades to suit different materials, cutting conditions, and desired surface finishes.

* **Drilling:** Indexable drills are used for creating holes in materials. Unlike solid drills, they allow for higher feed rates and offer excellent chip evacuation, making them ideal for deep hole drilling and large diameter holes.

* **Grooving and Parting:** Indexable inserts specifically designed for grooving and parting operations enable efficient creation of grooves and precise separation of workpieces.

* **Boring:** Indexable boring bars are used for enlarging or refining existing holes. They provide good surface finish and dimensional accuracy, especially in internal machining.These tools are prevalent in industries such as automotive, aerospace, medical, and general manufacturing, where high precision, productivity, and economic efficiency are crucial.

How do you install and replace indexable inserts?

Installing and replacing indexable inserts involves several key steps to ensure proper function and safety. First, always wear appropriate personal protective equipment (PPE), including safety glasses and gloves. Before starting, ensure the tool holder is clean and free of chips or debris, as this can affect insert seating and performance.

To install a new insert, carefully place it into the insert pocket, making sure it aligns correctly with the pocket's geometry. Most inserts have a specific orientation, so check for any alignment marks or features. Then, use the appropriate clamping screw or lever to secure the insert. Tighten the screw to the manufacturer's recommended torque specification, typically found in the tool holder's manual or on the insert packaging. Over-tightening can damage the insert or holder, while under-tightening can lead to instability during machining.

To replace an insert, first loosen and remove the clamping screw. Carefully remove the worn or broken insert from the pocket. Clean the insert pocket thoroughly with compressed air or a brush to remove any residual chips or coolant. Then, proceed with the installation steps for the new insert as described above. Regularly inspect the tool holder for wear or damage to the insert pocket, as a compromised pocket can lead to poor insert performance or premature failure.

What are the cost benefits of using indexable cutting tools over solid tools?

Indexable cutting tools offer several cost benefits over solid tools, primarily due to their design. One major advantage is reduced tooling costs. Instead of replacing the entire tool when it wears, only the small, interchangeable inserts need to be replaced. This significantly lowers material costs and waste.

Another key benefit is increased productivity. Indexable tools often allow for higher cutting speeds and feeds, leading to faster material removal and shorter cycle times. When an insert wears, it can be quickly indexed to a new cutting edge or replaced in seconds, minimizing machine downtime and maximizing production output. Solid tools, on the other hand, require resharpening, which takes time and can degrade the tool's performance over repeated cycles.

Furthermore, inventory management is simpler and more cost-effective with indexable tools. A single tool body can accommodate various insert geometries and grades, reducing the need to stock a wide range of solid tools for different applications. This optimizes inventory levels and frees up capital. The ability to use different inserts on the same tool body also provides greater versatility, allowing for different machining operations without changing the entire tool. This adaptability can lead to more efficient use of machines and personnel.

How do indexable cutting tools perform in high-speed and high-feed operations?

Indexable cutting tools are well-suited for high-speed and high-feed operations due to their design, which allows for quick insert changes without removing the tool from the machine. This minimizes downtime and increases productivity. The inserts, typically made from advanced materials like carbide, ceramics, or CBN, are engineered to withstand the extreme temperatures and forces generated during such aggressive machining. Their geometries are often optimized for efficient chip evacuation and reduced cutting forces, which are crucial for maintaining stability and accuracy at high speeds.

In high-speed operations, the tool's ability to dissipate heat is critical. Indexable tools often feature coolant through capabilities to deliver coolant directly to the cutting zone, extending tool life and improving surface finish. For high-feed applications, the robust construction of the tool body and the secure clamping of the inserts ensure stability and resistance to deflection, allowing for deeper cuts and faster material removal rates. The ability to replace worn inserts quickly also means that cutting performance can be consistently maintained, avoiding the degradation of surface finish or dimensional accuracy that can occur with resharpenable tools.