Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

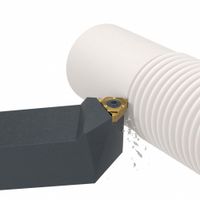

- Machining

- Indexable Cutting Tools

- Indexable Threading

.....Read More

Frequently Asked Questions

What is indexable threading?

Indexable threading is a machining process that involves the use of specialized tools with replaceable cutting inserts to create threads on a workpiece. These inserts are typically made from materials like carbide or ceramic, which are known for their durability and ability to withstand high temperatures and pressures. The key advantage of indexable threading is the ability to replace worn or damaged inserts without having to replace the entire tool, which reduces costs and downtime.

In indexable threading, the tool holder is designed to securely hold the inserts in place, allowing for precise and consistent thread production. The inserts are available in various shapes and sizes to accommodate different thread profiles and pitches, making the process versatile for a wide range of applications. The inserts can be indexed, or rotated, to expose a fresh cutting edge, further extending the tool's life.

This method is commonly used in CNC (Computer Numerical Control) machining, where precision and efficiency are critical. The process is suitable for both internal and external threading and can be applied to a variety of materials, including metals, plastics, and composites.

Indexable threading offers several benefits, including reduced tool inventory, as a single tool holder can accommodate multiple insert types. It also enhances productivity by minimizing tool changeover time and maintaining consistent thread quality. Additionally, the use of high-performance insert materials allows for higher cutting speeds and feeds, improving overall machining efficiency.

Overall, indexable threading is a cost-effective and efficient solution for producing high-quality threads in industrial manufacturing settings.

How does indexable threading differ from traditional threading methods?

Indexable threading differs from traditional threading methods primarily in tool design, efficiency, and cost-effectiveness.

1. **Tool Design**: Indexable threading uses inserts that can be replaced or indexed, meaning the cutting edge can be rotated or flipped to a new edge without changing the entire tool. Traditional threading often uses solid tools that require regrinding or replacement when worn.

2. **Efficiency**: Indexable threading allows for quick changes of the cutting edge, reducing downtime and increasing productivity. Traditional methods may require more time for tool changes and maintenance, impacting overall efficiency.

3. **Cost-Effectiveness**: With indexable threading, only the insert needs replacement, which is generally cheaper than replacing an entire tool. Traditional threading tools can be more expensive over time due to the need for complete tool replacement or regrinding.

4. **Versatility**: Indexable threading tools can accommodate a variety of thread profiles and pitches by simply changing the insert, offering greater flexibility. Traditional tools may require different tools for different thread types.

5. **Precision and Consistency**: Indexable threading provides consistent performance and precision due to the standardized manufacturing of inserts. Traditional tools may suffer from inconsistencies due to wear and manual regrinding.

6. **Material Suitability**: Indexable threading is suitable for a wide range of materials, including hard-to-machine alloys, due to the availability of specialized insert coatings and geometries. Traditional methods may struggle with such materials.

7. **Heat Management**: Indexable inserts often have better heat dissipation properties, reducing the risk of tool failure and improving surface finish. Traditional tools may not manage heat as effectively, leading to potential quality issues.

Overall, indexable threading offers advantages in terms of flexibility, cost, and efficiency, making it a preferred choice in many modern machining operations.

What are the advantages of using indexable threading tools?

Indexable threading tools offer several advantages:

1. **Cost Efficiency**: Indexable tools have replaceable inserts, reducing the need to replace the entire tool. This lowers the cost per threading operation and minimizes inventory requirements.

2. **Versatility**: These tools can accommodate various thread profiles and pitches by simply changing the insert, making them suitable for a wide range of applications without needing multiple tools.

3. **Reduced Downtime**: Quick insert changes minimize machine downtime, enhancing productivity. Operators can swiftly replace worn inserts without removing the tool holder from the machine.

4. **Consistent Quality**: Indexable inserts are manufactured to precise specifications, ensuring consistent thread quality and accuracy across multiple operations.

5. **Material Efficiency**: The use of advanced coatings and materials in inserts enhances tool life and performance, especially in challenging materials, reducing the frequency of insert changes.

6. **Improved Chip Control**: Many indexable threading tools are designed with features that improve chip evacuation, reducing the risk of damage to the workpiece and tool.

7. **Flexibility**: They can be used in both internal and external threading applications, providing flexibility in machining operations.

8. **Reduced Tool Inventory**: With the ability to use different inserts for various threading tasks, the need for a large inventory of different tools is reduced.

9. **Enhanced Performance**: The design of indexable tools often allows for higher cutting speeds and feeds, improving overall machining efficiency.

10. **Environmental Benefits**: By only replacing the insert rather than the entire tool, waste is reduced, contributing to more sustainable manufacturing practices.

What types of materials can be threaded using indexable threading?

Indexable threading can be used on a wide range of materials, including:

1. **Steel**: Low carbon, medium carbon, and high carbon steels, as well as alloy steels, can be threaded using indexable tools. This includes both ferrous and non-ferrous steels.

2. **Stainless Steel**: Austenitic, martensitic, and ferritic stainless steels are suitable for indexable threading, though they may require specific insert grades to handle their toughness and work-hardening properties.

3. **Cast Iron**: Both gray and ductile cast irons can be threaded effectively with indexable tools, benefiting from their brittleness and ease of chip breaking.

4. **Aluminum**: Due to its softness and tendency to stick, aluminum requires sharp, polished inserts for effective threading.

5. **Titanium**: Although challenging due to its strength and tendency to work harden, titanium can be threaded with the right insert geometry and coating.

6. **Nickel Alloys**: Materials like Inconel and Monel, known for their high strength and corrosion resistance, can be threaded using specialized indexable inserts designed to withstand high temperatures and pressures.

7. **Copper and Brass**: These softer metals are easily threaded with indexable tools, though care must be taken to avoid galling.

8. **Plastics**: Certain plastics can be threaded using indexable tools, provided the inserts are sharp and the cutting parameters are adjusted to prevent melting or deformation.

9. **Composites**: Some composite materials can be threaded, though this often requires specialized inserts to handle the abrasive nature of the material.

10. **Hardened Materials**: With the right insert materials and coatings, even hardened steels and other tough materials can be threaded using indexable tools.

Indexable threading tools are versatile and can be adapted to a wide range of materials by selecting the appropriate insert geometry, material, and coating.

How do you select the right indexable threading insert for a specific application?

To select the right indexable threading insert for a specific application, consider the following factors:

1. **Thread Type and Profile**: Determine the thread type (e.g., metric, UN, ACME) and profile (e.g., V-thread, trapezoidal) required for the application. This ensures compatibility with the desired thread form.

2. **Material of Workpiece**: Identify the material being machined (e.g., steel, stainless steel, aluminum). Different materials require inserts with specific coatings and geometries to optimize performance and tool life.

3. **Insert Geometry**: Choose the appropriate insert geometry based on the thread profile and pitch. The geometry affects chip control, surface finish, and cutting forces.

4. **Coating and Grade**: Select the insert coating and grade based on the workpiece material and machining conditions. Coatings like TiN, TiCN, or AlTiN enhance wear resistance and heat dissipation.

5. **Machine and Toolholder Compatibility**: Ensure the insert is compatible with the machine tool and toolholder. Consider the insert size, shape, and clamping system to fit the existing setup.

6. **Cutting Conditions**: Evaluate the cutting speed, feed rate, and depth of cut. Inserts are designed for specific ranges of these parameters, affecting tool life and thread quality.

7. **Production Volume**: For high-volume production, prioritize inserts with longer tool life and consistent performance. For low-volume or prototype work, flexibility and cost-effectiveness may be more important.

8. **Surface Finish Requirements**: Consider the required surface finish of the threads. Some inserts are designed to produce smoother finishes, which may be necessary for certain applications.

9. **Cost and Availability**: Balance the cost of the insert with its performance benefits. Ensure the chosen insert is readily available to avoid production delays.

By carefully evaluating these factors, you can select the most suitable indexable threading insert for your specific application, ensuring efficient and high-quality thread production.

What are the common challenges faced in indexable threading and how can they be overcome?

Common challenges in indexable threading include:

1. **Tool Wear and Breakage**: Indexable threading tools can wear out or break due to high cutting forces and heat. To overcome this, use high-quality, coated inserts and ensure proper cooling and lubrication.

2. **Chip Control**: Poor chip evacuation can lead to tool damage and poor surface finish. Implement effective chip breakers and optimize cutting parameters to improve chip control.

3. **Vibration and Chatter**: These can affect thread quality and tool life. To mitigate this, use rigid setups, optimize cutting speeds and feeds, and consider using dampened tool holders.

4. **Thread Accuracy**: Achieving precise thread dimensions can be challenging. Regularly calibrate machines, use high-precision tools, and ensure proper alignment and setup.

5. **Material Variability**: Different materials can affect tool performance. Select appropriate insert grades and geometries for the specific material being threaded.

6. **Insert Indexing**: Incorrect indexing can lead to poor thread quality. Use precise indexing systems and regularly check for wear or damage.

7. **Machine Limitations**: Older machines may lack the precision required for high-quality threading. Upgrade to modern CNC machines with advanced threading capabilities if necessary.

8. **Complex Thread Forms**: Creating non-standard thread forms can be difficult. Use specialized software and tools designed for complex threading operations.

9. **Cost Management**: High-quality inserts and tools can be expensive. Implement a tool management system to track tool life and optimize usage.

10. **Operator Skill**: Inexperienced operators may struggle with setup and operation. Provide comprehensive training and use user-friendly interfaces to assist operators.

By addressing these challenges with appropriate strategies and technologies, the efficiency and quality of indexable threading operations can be significantly improved.

How do you maintain and care for indexable threading tools?

To maintain and care for indexable threading tools, follow these steps:

1. **Regular Inspection**: Frequently check the tool for wear, damage, or chipping. Inspect the insert seats and clamping mechanisms to ensure they are free from debris and damage.

2. **Proper Cleaning**: After each use, clean the tool and inserts thoroughly. Use a soft brush or compressed air to remove chips and debris. Avoid using harsh chemicals that could damage the tool.

3. **Correct Storage**: Store tools in a clean, dry environment. Use protective cases or racks to prevent physical damage. Ensure that inserts are stored in their original packaging to avoid chipping.

4. **Insert Handling**: Handle inserts with care to prevent chipping. Use appropriate tools for insert changes, and avoid touching the cutting edges with bare hands to prevent corrosion from oils and moisture.

5. **Secure Clamping**: Ensure that inserts are clamped securely in the tool holder. Use the recommended torque settings to avoid over-tightening, which can lead to insert breakage or tool holder damage.

6. **Tool Holder Maintenance**: Regularly check the tool holder for wear and damage. Ensure that the holder is free from burrs and that the insert seat is in good condition to maintain proper alignment and cutting performance.

7. **Coolant Use**: Use appropriate coolant to reduce heat and extend tool life. Ensure that the coolant is clean and properly directed at the cutting zone.

8. **Proper Usage**: Follow manufacturer guidelines for speed, feed, and depth of cut. Avoid exceeding recommended parameters to prevent premature wear or tool failure.

9. **Record Keeping**: Maintain a log of tool usage, including hours of operation and any maintenance performed. This helps in predicting tool life and scheduling preventive maintenance.

10. **Training**: Ensure that operators are trained in the proper handling and maintenance of threading tools to maximize tool life and performance.