Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

- Indexable Cutting Tools

- Indexable Threading

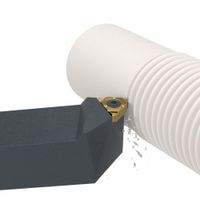

- Indexable Thread Turning

.....Read More

Frequently Asked Questions

What is indexable thread turning?

Indexable thread turning is a machining process used to create threads on a workpiece using a lathe. It involves the use of indexable inserts, which are cutting tools with replaceable cutting edges. These inserts are mounted on a tool holder and can be indexed, or rotated, to present a fresh cutting edge when one becomes worn, thus extending the tool's life and reducing downtime.

The process begins with selecting the appropriate indexable insert based on the material of the workpiece and the thread specifications, such as pitch and profile. The insert is then securely clamped into a tool holder, which is mounted on the lathe's tool post. The workpiece is rotated at a specific speed, and the tool is fed into the workpiece at a precise rate to cut the thread.

Indexable thread turning offers several advantages over traditional threading methods. The use of replaceable inserts reduces the need for regrinding or replacing entire tools, leading to cost savings. The precision of the inserts ensures consistent thread quality and accuracy. Additionally, the ability to quickly change inserts allows for efficient handling of different thread types and sizes.

The process is suitable for a wide range of materials, including metals and plastics, and can be used to produce both internal and external threads. It is commonly employed in industries such as automotive, aerospace, and manufacturing, where high precision and efficiency are critical.

Overall, indexable thread turning is a versatile and efficient method for producing high-quality threads, offering flexibility, cost-effectiveness, and precision in machining operations.

How does an indexable threading tool work?

An indexable threading tool is designed for cutting threads on a workpiece using replaceable cutting inserts. These tools are commonly used in CNC lathes and other machining centers for efficient and precise thread production. The tool consists of a tool holder and an indexable insert, which is the cutting component.

The tool holder is designed to securely hold the insert in place and is mounted on the machine's tool post. The insert, typically made from carbide or other hard materials, has multiple cutting edges. When one edge becomes dull or damaged, the insert can be rotated or indexed to present a fresh cutting edge, thus extending the tool's life and reducing downtime.

The threading process begins with the tool being positioned at the starting point of the thread on the workpiece. The machine is programmed with the thread's specifications, such as pitch, depth, and length. As the workpiece rotates, the tool moves along its axis, cutting the thread profile into the material. The insert's geometry is designed to match the thread profile, ensuring accurate and consistent thread production.

Indexable threading tools offer several advantages, including reduced tool change time, cost-effectiveness due to the replaceable inserts, and the ability to handle various thread forms and sizes by simply changing the insert. They also provide high precision and repeatability, essential for producing high-quality threads in mass production settings.

Overall, indexable threading tools are a versatile and efficient solution for thread cutting, combining the benefits of replaceable inserts with the precision and adaptability required in modern machining operations.

What are the benefits of using indexable thread turning tools?

Indexable thread turning tools offer several benefits:

1. **Cost Efficiency**: These tools use replaceable inserts, reducing the need to replace the entire tool when the cutting edge wears out. This lowers overall tooling costs.

2. **Versatility**: They can accommodate a variety of thread profiles and pitches by simply changing the insert, making them suitable for different threading applications without needing multiple tools.

3. **Reduced Downtime**: Quick and easy insert changes minimize machine downtime, enhancing productivity and efficiency in manufacturing processes.

4. **Consistent Quality**: Indexable inserts are manufactured to precise specifications, ensuring consistent thread quality and accuracy across multiple parts.

5. **Material Flexibility**: They are suitable for a wide range of materials, from soft metals to hard alloys, by selecting the appropriate insert grade and geometry.

6. **Improved Tool Life**: Advanced coatings and materials used in inserts enhance wear resistance and heat dissipation, extending tool life and maintaining performance.

7. **Enhanced Performance**: The ability to optimize cutting parameters for specific materials and applications leads to improved cutting performance and surface finish.

8. **Inventory Management**: Fewer complete tools are needed in inventory, as different inserts can be used with the same tool holder, simplifying stock management.

9. **Environmental Benefits**: Reduced waste from not discarding entire tools contributes to more sustainable manufacturing practices.

10. **Safety and Ease of Use**: The design of indexable tools often allows for safer handling and easier setup, reducing the risk of injury and errors during tool changes.

How do you change inserts on an indexable threading tool?

1. **Safety First**: Ensure the machine is turned off and locked out. Wear appropriate personal protective equipment, such as gloves and safety glasses.

2. **Prepare the Tool**: Secure the indexable threading tool in a stable position, either in a tool holder or a vise, to prevent movement during the insert change.

3. **Identify the Insert**: Locate the worn or damaged insert on the threading tool. Note the orientation and position of the insert for correct reinstallation.

4. **Loosen the Screw**: Use the appropriate wrench or screwdriver to loosen the screw or clamp that holds the insert in place. Be careful not to strip the screw head.

5. **Remove the Insert**: Carefully remove the old insert. If it is stuck, gently tap it with a soft mallet or use a small tool to pry it out, taking care not to damage the tool body.

6. **Clean the Pocket**: Use a brush or compressed air to clean the insert pocket, removing any debris or chips that could affect the seating of the new insert.

7. **Select the New Insert**: Choose a new insert that matches the specifications of the old one, ensuring compatibility with the tool and the material being threaded.

8. **Install the New Insert**: Place the new insert into the pocket, aligning it correctly as per the original orientation. Ensure it sits flush and is properly seated.

9. **Tighten the Screw**: Secure the insert by tightening the screw or clamp. Use the recommended torque setting to avoid over-tightening, which can damage the insert or tool.

10. **Inspect the Setup**: Double-check the installation to ensure the insert is secure and correctly positioned.

11. **Test the Tool**: Once reassembled, perform a test cut on a scrap piece to verify the insert is functioning correctly. Adjust if necessary.

What materials can be used with indexable thread turning?

Indexable thread turning can be used with a variety of materials, including:

1. **Steel**: Both carbon and alloy steels are commonly machined using indexable thread turning tools. These materials are prevalent in automotive and construction industries.

2. **Stainless Steel**: Due to its corrosion resistance and strength, stainless steel is often used in applications requiring durability. Indexable tools are designed to handle its toughness.

3. **Cast Iron**: This material is used in heavy machinery and automotive parts. Indexable tools can efficiently cut through its brittle structure.

4. **Aluminum**: Known for its lightweight and machinability, aluminum is used in aerospace and automotive industries. Indexable tools can achieve high-speed machining with aluminum.

5. **Titanium**: Used in aerospace and medical applications for its strength-to-weight ratio, titanium requires specialized indexable tools to manage its work-hardening properties.

6. **Brass and Copper**: These materials are used in electrical and plumbing applications. Indexable tools can handle their softness and ductility.

7. **Nickel Alloys**: Known for high-temperature resistance, nickel alloys are used in aerospace and power generation. Indexable tools are designed to manage their toughness.

8. **Plastics and Composites**: These materials are used in various industries for their lightweight and corrosion resistance. Indexable tools can be adapted for their specific cutting requirements.

9. **Hardened Materials**: Indexable tools with specialized coatings and geometries can be used for machining hardened materials, often found in tool and die applications.

10. **Exotic Alloys**: Materials like Inconel and Hastelloy, used in extreme environments, can be machined with indexable tools designed for high heat and wear resistance.

Indexable thread turning tools are versatile and can be tailored with different coatings and geometries to optimize performance across these materials.

What are the differences between indexable and solid threading tools?

Indexable threading tools use replaceable inserts that can be rotated or changed when worn, allowing for cost-effective maintenance and versatility in handling various thread profiles. They are ideal for high-volume production due to their ability to maintain consistent quality and reduce downtime. The inserts are typically made from carbide or other durable materials, providing excellent wear resistance and heat management.

Solid threading tools, on the other hand, are made from a single piece of material, often high-speed steel or carbide. They are generally more rigid and can offer better precision and surface finish for specific applications. Solid tools are typically used for smaller production runs or specialized threading tasks where the tool's rigidity and precision are paramount.

The main differences lie in cost, flexibility, and application suitability. Indexable tools are more economical for large-scale operations due to their replaceable nature, while solid tools are preferred for precision and smaller-scale tasks.

How do you select the right indexable threading insert for a specific application?

To select the right indexable threading insert for a specific application, consider the following factors:

1. **Thread Type and Profile**: Determine the thread type (e.g., metric, UN, ACME) and profile required for the application. Ensure the insert matches the thread standards and profile dimensions.

2. **Material Compatibility**: Choose an insert material and coating that are compatible with the workpiece material. Common materials include carbide and cermet, with coatings like TiN or TiAlN for enhanced wear resistance.

3. **Insert Geometry**: Select the appropriate insert geometry based on the threading operation (internal or external) and the machine's capabilities. Consider the insert's shape, size, and cutting edge design for optimal performance.

4. **Pitch and TPI (Threads Per Inch)**: Ensure the insert can accommodate the required thread pitch or TPI. Inserts are often designed for specific pitch ranges.

5. **Machine and Toolholder Compatibility**: Verify that the insert is compatible with the machine tool and toolholder. Consider the insert's clamping system and ensure it fits securely in the toolholder.

6. **Cutting Conditions**: Assess the cutting speed, feed rate, and depth of cut. Choose an insert that can withstand the specific cutting conditions without compromising tool life or thread quality.

7. **Surface Finish Requirements**: Consider the desired surface finish of the threads. Some inserts are designed to produce smoother finishes, which may be necessary for certain applications.

8. **Cost and Availability**: Evaluate the cost-effectiveness and availability of the insert. Balance performance needs with budget constraints.

9. **Manufacturer Recommendations**: Consult manufacturer catalogs and technical support for recommendations based on specific application requirements.

10. **Trial and Testing**: Conduct trials to test the insert's performance in real-world conditions, making adjustments as necessary to optimize results.