Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What is threading in machining?

Threading in machining is the process of creating a screw thread. This can be done on the external surface of a workpiece (external threading) or on the internal surface (internal threading). It involves using a cutting tool to create a helical groove with a specific pitch and form. Common methods include turning with a single-point tool, tapping (for internal threads using a tap), and die threading (for external threads using a die). The process is crucial for creating fasteners, connecting parts, and transmitting power in various mechanical applications.

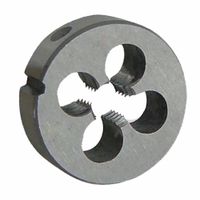

How does a threading die work?

A threading die is a tool used to cut external screw threads on a cylindrical rod or bar. It works by having a series of cutting edges arranged in a circular pattern, with a central hole that matches the size of the rod. As the die is rotated and advanced onto the rod, the cutting edges progressively remove material, forming the helical grooves of the thread.

There are different types of threading dies, including solid dies, adjustable dies, and two-piece dies. Solid dies are fixed in size and used for standard thread sizes. Adjustable dies allow for minor adjustments to the thread diameter, while two-piece dies (also known as chasers) are used in die heads for more precise control and larger diameter threads. The material being threaded and the desired thread form influence the choice of die. Proper lubrication is essential during the threading process to reduce friction, dissipate heat, and ensure a smooth, accurate thread.

What is the difference between a tap and a die?

A tap and a die are both tools used to create threads, but they serve opposite purposes. A tap is used to cut internal threads, such as those inside a nut or a hole. It has cutting edges along its length that create the helical groove within a pre-drilled hole. Dies, on the other hand, are used to cut external threads, like those on a bolt or a rod. A die works by cutting threads onto the outside of a cylindrical workpiece. Both tools are essential for fastening applications, allowing parts to be screwed together securely.

How do you use a tap to cut internal threads?

To cut internal threads with a tap, first ensure the hole is drilled to the correct tap drill size for the desired thread. This is crucial for proper thread formation. Chamfer the entrance of the hole slightly to aid in starting the tap. Secure the workpiece firmly to prevent movement during the tapping process.

Select the appropriate tap for the thread size and pitch. There are typically three types of hand taps: taper, plug, and bottoming. Start with a taper tap (if available) as its tapered lead makes it easier to start straight. Insert the tap into the hole and align it perpendicular to the workpiece surface. Use a tap wrench to turn the tap.

Apply gentle downward pressure and turn the tap clockwise (for right-hand threads) for two full turns. Then, turn it counter-clockwise for about half a turn to break the chips. This prevents chip buildup and reduces the risk of tap breakage. Continue this "two steps forward, one step back" motion, lubricating the tap frequently with cutting oil appropriate for the material being threaded. This lubrication reduces friction, improves thread quality, and extends tap life.

As you tap deeper, ensure the tap remains straight. If resistance increases significantly, clear the chips more frequently or consider using a different tap type (e.g., plug tap after a taper tap). Once the tap has gone through the desired depth, carefully back it out by turning it counter-clockwise, making sure to clear any remaining chips. Clean the newly cut threads of any oil or debris.

What materials can be threaded using taps and dies?

Taps and dies are versatile tools used to create threads in a variety of materials, primarily metals and some plastics. The specific material dictates the type of tap and die needed, as well as the cutting fluid and technique.

Common materials threaded with taps and dies include: * Steel (mild, carbon, alloy, stainless): Widely threaded for fasteners and structural components. Different grades require varying tap and die hardness and cutting speeds.

* Aluminum: Relatively soft and easy to thread, but prone to galling without proper lubrication.

* Brass and Bronze: Good for threading, often producing clean threads.

* Cast Iron: Can be threaded, but its brittle nature requires careful handling to prevent chipping.

* Copper: Soft and ductile, requiring sharp tools and good lubrication to prevent deformation.

* Plastics (e.g., PVC, acrylic, nylon): Can be threaded, but require specific taps designed for plastics to avoid cracking or melting, and often at lower speeds.Less common or more challenging materials include titanium and high-strength alloys, which demand specialized, harder taps and dies, often with advanced coatings and specific cutting fluids. The choice of tap and die material (e.g., high-speed steel, cobalt, carbide) and thread form are crucial for successful and durable threading in any given material.

How do you repair damaged threads?

Repairing damaged threads typically involves a few common methods depending on the severity and type of damage.

For minor damage, a thread file can be used to re-form the peaks and valleys of the existing threads. This is often effective for external threads that have been slightly flattened or distorted. A tap (for internal threads) or a die (for external threads) can also be run over the damaged area to clean up and recut the threads, provided there's enough material left to work with.

If the threads are significantly stripped or cross-threaded, more robust solutions are needed. One common method is to use a thread repair insert kit, such as a Helicoil or similar product. This involves drilling out the damaged threads, tapping a new, larger hole, and then screwing in a helical insert that provides new, strong threads of the original size. This is a very durable repair.

Another option for severely damaged internal threads is to bore out the hole and press in a solid bushing or insert that has the correct internal threads. This requires precision machining but can create a very robust repair.

For external threads, if a section is severely damaged, it might be possible to cut off the damaged portion and re-thread the remaining shaft, if the length allows. Alternatively, a welding repair might be considered where new material is added and then machined and threaded.

The best method depends on the material, the size of the threads, the extent of the damage, and the desired strength of the repair. It's crucial to use the correct tools and follow proper procedures to ensure the repaired threads are functional and reliable.

What are the types of threading tools?

Threading tools are essential for creating screw threads on various materials, enabling components to be joined securely. There are several types of threading tools, each designed for specific applications and materials.

One common type is the tap, used to cut internal threads. Taps come in different forms, including hand taps (taper, plug, and bottoming for sequential use), machine taps (for faster operation), and form taps (which create threads by deforming material rather than cutting, ideal for softer materials).

For external threads, dies are used. Dies can be solid (fixed size), adjustable (allowing slight diameter changes), or split (for precise adjustments). Die stocks hold the dies and are turned manually.

Thread mills are another type of threading tool, typically used in CNC machines. They are rotating tools that cut threads by orbiting around the workpiece, offering versatility for large or internal threads, and improved chip evacuation.

Finally, thread chasers are used for repairing or cleaning existing threads, often on fasteners or pipes, without recutting them entirely. Each tool serves a unique purpose in the intricate process of thread creation and maintenance.

How do you choose the right tap or die size?

Choosing the right tap or die size is crucial for creating precise and strong threads. The primary factor is the desired thread diameter and pitch. These specifications are typically determined by the fasteners or components you'll be using.

Taps are used to create internal threads (e.g., in a nut or a drilled hole), while dies are used for external threads (e.g., on a bolt or a rod). Both taps and dies come in various threading standards, with the most common being: * **Unified National Coarse (UNC) and Unified National Fine (UNF):** These are common in North America, with UNC threads being coarser and UNF threads being finer.

* **Metric (M):** Widely used globally, metric threads are designated by their nominal diameter in millimeters and their pitch (distance between threads) in millimeters.

* **British Standard Whitworth (BSW) and British Standard Fine (BSF):** Older British standards, less common now.Once you know the required diameter and pitch, you'll select the corresponding tap or die. For taps, it's also critical to drill the correct pilot hole size. A tap drill chart will specify the exact drill bit diameter needed for a given tap size to ensure the thread has the proper depth and strength. Using an incorrect pilot hole size can lead to stripped threads or broken taps.

Consider the material you are threading. Harder materials may require different tap geometries or lubricants. Also, determine if you need a "bottoming," "taper," or "plug" tap based on the depth of the hole you are threading.

What safety precautions should be taken when threading?

When performing threading, it is crucial to prioritize safety to prevent injuries and ensure a successful outcome. First and foremost, always wear appropriate personal protective equipment (PPE). This includes safety glasses or a face shield to protect your eyes from flying debris or hot chips, and gloves to protect your hands from sharp edges and hot surfaces. Avoid wearing loose clothing, jewelry, or long hair that could get caught in rotating machinery.

Before starting, ensure that the workpiece is securely clamped in a vice or chuck to prevent it from moving during the threading process. A stable setup is essential for accuracy and safety. Inspect your tools, including the tap or die, for any damage or wear. Using damaged tools can lead to inaccurate threads, tool breakage, and potential injury.

During the threading operation, apply a suitable cutting fluid. This reduces friction and heat, prolongs tool life, and helps to create cleaner threads. Be mindful of the pressure you apply; excessive force can break the tap or die. For internal threading, use a tap handle that provides good leverage and control. For external threading, ensure the die is properly seated in the die stock.

Periodically clear chips to prevent them from accumulating and interfering with the cutting action. Use a brush or hook, never your bare hands, to remove chips. If the tool binds or becomes difficult to turn, back it off, clear any chips, and reapply cutting fluid before continuing.

Finally, always be aware of your surroundings and avoid distractions. Keep your work area clean and well-lit. Proper safety precautions will ensure a safe and efficient threading process.

How do you maintain and store threading tools?

Maintaining and storing threading tools properly is crucial for their longevity and performance. Regular cleaning is the first step; after each use, remove any chips, oil, or debris with a brush or cloth. For taps and dies, ensure the threads are clear to prevent buildup that can affect future cuts.

Lubrication is also vital. Applying a thin coat of rust-preventative oil to the cutting edges and surfaces of threading tools after cleaning helps protect them from corrosion, especially in humid environments. This is particularly important for high-carbon steel tools.

Proper storage prevents damage and rust. Tools should be stored in individual compartments or padded cases to prevent them from knocking against each other, which can dull or chip the cutting edges. Many threading tool sets come with dedicated cases, which are ideal. If not, consider using tool rolls, drawer organizers, or magnetic strips that keep tools separate and secure. Ensure the storage area is dry and free from extreme temperature fluctuations.

For larger threading tools, like those used in pipe threading, consider wall-mounted racks or dedicated stands that keep them organized and off the floor, reducing the risk of accidental damage. Regularly inspect your tools for any signs of wear, damage, or rust, and address issues promptly to maintain their effectiveness.