Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

- Drilling Holemaking

- Drill Bits

.....Read More

Frequently Asked Questions

What are the different types of drill bits?

Drill bits come in various types, each designed for specific materials and purposes:

1. **Twist Drill Bits**: The most common type, used for wood, metal, and plastic. They have a helical shape that helps remove debris.

2. **Brad Point Bits**: Ideal for wood, these bits have a sharp point for precise entry and clean holes.

3. **Masonry Bits**: Designed for drilling into concrete, brick, and stone. They have a carbide tip to withstand hard surfaces.

4. **Spade Bits**: Used for wood, these flat bits are ideal for making large holes quickly.

5. **Forstner Bits**: Perfect for creating flat-bottomed holes in wood, often used in cabinetry.

6. **Auger Bits**: Designed for deep, clean holes in wood, featuring a screw tip for easy starting.

7. **Step Bits**: Cone-shaped bits used for drilling holes of various sizes in metal and plastic.

8. **Hole Saw Bits**: Used for cutting large holes in wood, metal, and plastic, often for doorknobs or pipes.

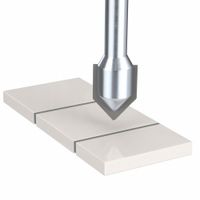

9. **Countersink Bits**: Create a conical hole for screw heads to sit flush with or below the surface.

10. **Tile Bits**: Specifically for ceramic tiles, these bits have a spear-shaped tip to prevent cracking.

11. **Glass Bits**: Designed for glass and ceramic, featuring a tungsten carbide tip.

12. **Cobalt Bits**: Made for hard metals, these bits are heat-resistant and durable.

13. **Titanium Bits**: Coated for increased durability and reduced friction, suitable for metal and wood.

14. **Diamond Bits**: Used for cutting through very hard materials like glass and stone, featuring a diamond coating.

15. **Pilot Point Bits**: Provide precise drilling with a smaller pilot tip to prevent walking.

Each type of drill bit is engineered to optimize performance for specific tasks, ensuring efficiency and precision in drilling operations.

How do I choose the right drill bit for my project?

To choose the right drill bit for your project, consider the following factors:

1. **Material**: Match the drill bit material to the material you're drilling. High-speed steel (HSS) is versatile for wood, plastic, and soft metals. Cobalt bits are ideal for hard metals like stainless steel. Carbide-tipped bits are best for masonry and concrete.

2. **Bit Type**: Select the bit type based on the task:

- **Twist Bits**: General-purpose, suitable for wood, metal, and plastic.

- **Brad Point Bits**: Ideal for wood, providing clean holes.

- **Masonry Bits**: Designed for concrete, brick, and stone.

- **Spade Bits**: Best for large holes in wood.

- **Forstner Bits**: Create flat-bottomed holes in wood.

- **Auger Bits**: Efficient for deep holes in wood.

- **Hole Saws**: Cut large diameter holes in wood, metal, or plastic.

3. **Size**: Choose the correct diameter and length. The diameter should match the size of the hole you need, while the length should accommodate the depth of the material.

4. **Shank Type**: Ensure compatibility with your drill. Round shanks fit most drills, while hex shanks provide a better grip and are often used in quick-change systems.

5. **Coating**: Consider coatings for enhanced performance. Titanium-coated bits last longer and reduce friction. Black oxide offers corrosion resistance.

6. **Project Requirements**: Assess the precision and finish needed. For delicate work, use bits that provide clean cuts and minimal tear-out.

7. **Budget and Frequency of Use**: For occasional use, standard bits may suffice. For frequent or professional use, invest in higher-quality bits for durability and performance.

By evaluating these factors, you can select the most suitable drill bit for your specific project needs.

What materials are drill bits made from?

Drill bits are crafted from a variety of materials, each chosen for specific properties that suit different drilling applications. High-Speed Steel (HSS) is a common material, known for its durability and ability to withstand high temperatures, making it suitable for drilling wood, plastic, and soft metals. Cobalt drill bits, an alloy of HSS with cobalt, offer enhanced heat resistance and hardness, ideal for drilling stainless steel and other hard metals.

Carbide-tipped drill bits feature a steel body with a carbide tip, providing exceptional hardness and heat resistance, perfect for drilling into masonry, tile, and other hard materials. Solid carbide drill bits, made entirely from carbide, are used for high-precision applications and can cut through the hardest materials, including cast iron and non-ferrous metals.

Diamond drill bits are embedded with diamond particles, offering superior cutting ability for glass, ceramics, and stone. These bits are often used in specialized applications where precision and smooth finishes are required.

Titanium-coated drill bits are HSS bits with a titanium nitride coating, which reduces friction and increases wear resistance, extending the bit's lifespan. These are suitable for a variety of materials, including metal, wood, and plastic.

Black oxide drill bits are HSS bits treated with a black oxide finish to increase corrosion resistance and reduce friction, making them versatile for general-purpose drilling in wood and metal.

Each material offers distinct advantages, and the choice depends on the specific requirements of the drilling task, including the material to be drilled, the desired precision, and the operating conditions.

How do I sharpen a drill bit?

To sharpen a drill bit, follow these steps:

1. **Safety First**: Wear safety goggles and gloves to protect yourself from metal shavings.

2. **Tools Required**: Use a bench grinder or a dedicated drill bit sharpener. Ensure the grinder is stable and the wheel is appropriate for metal.

3. **Prepare the Grinder**: Turn on the grinder and let it reach full speed. Adjust the tool rest to a 60-degree angle, which is standard for most drill bits.

4. **Position the Drill Bit**: Hold the drill bit firmly with both hands. Position it at the correct angle against the grinding wheel. The cutting edge should be parallel to the wheel.

5. **Sharpen the Cutting Edge**: Gently press the bit against the wheel, maintaining the angle. Grind the cutting edge evenly, applying light pressure. Rotate the bit slightly to ensure even sharpening.

6. **Maintain the Angle**: Keep the original angle of the drill bit. Consistency is key to maintaining the bit’s effectiveness.

7. **Check the Bit**: After a few seconds of grinding, inspect the bit. The cutting edge should be sharp and symmetrical. The chisel edge should be centered.

8. **Cool the Bit**: Dip the bit in water frequently to prevent overheating, which can damage the temper of the metal.

9. **Repeat for the Other Side**: Flip the bit and repeat the process for the other cutting edge. Ensure both sides are symmetrical and sharp.

10. **Test the Bit**: After sharpening, test the bit on a piece of scrap material to ensure it drills effectively.

11. **Final Touches**: If necessary, use a fine file to remove any burrs or rough edges.

Regular maintenance and careful sharpening will extend the life of your drill bits.

What is the difference between HSS and carbide drill bits?

HSS (High-Speed Steel) and carbide drill bits differ primarily in material composition, performance, and application.

HSS drill bits are made from a combination of steel and other elements like chromium, vanadium, and tungsten. They are known for their toughness and ability to withstand high temperatures without losing hardness. HSS bits are versatile, suitable for drilling wood, plastic, and soft metals like aluminum and mild steel. They are cost-effective and can be resharpened, making them ideal for general-purpose use and applications where precision is not critical.

Carbide drill bits, on the other hand, are made from a composite of tungsten carbide and cobalt. They are significantly harder and more brittle than HSS bits. This hardness allows carbide bits to maintain a sharp cutting edge longer and perform well at higher speeds, making them suitable for drilling hard materials like stainless steel, cast iron, and non-ferrous metals. They are also used in applications requiring high precision and where tool longevity is crucial. However, carbide bits are more expensive and can be prone to chipping or breaking if not used properly.

In summary, HSS drill bits are preferred for their versatility and cost-effectiveness in general applications, while carbide drill bits are chosen for their superior hardness and performance in demanding, high-precision tasks.

How do I prevent drill bits from overheating?

To prevent drill bits from overheating, follow these steps:

1. **Proper Speed**: Use the correct drill speed for the material. Harder materials require slower speeds. Refer to a speed chart for guidance.

2. **Lubrication**: Apply cutting fluid or oil to the drill bit and workpiece. This reduces friction and dissipates heat. For metals, use specific cutting oils; for wood, water is sufficient.

3. **Sharp Bits**: Ensure drill bits are sharp. Dull bits generate more heat due to increased friction. Regularly sharpen or replace them.

4. **Appropriate Pressure**: Apply consistent, moderate pressure. Excessive force increases friction and heat. Let the drill do the work.

5. **Step Drilling**: For large holes, start with a smaller pilot hole. Gradually increase the bit size to reduce heat buildup.

6. **Cooling Breaks**: Periodically stop drilling to allow the bit to cool. This is crucial for prolonged drilling sessions.

7. **Material-Specific Bits**: Use drill bits designed for the specific material. For example, use masonry bits for concrete and cobalt or carbide bits for metal.

8. **Drill Type**: Use a drill with variable speed control for better management of speed and pressure.

9. **Ventilation**: Ensure good airflow around the work area to help dissipate heat.

10. **Proper Technique**: Maintain a steady hand and angle to prevent binding, which can cause overheating.

By following these practices, you can effectively prevent drill bits from overheating, ensuring longer tool life and better performance.

What coatings are available for drill bits and what are their benefits?

Drill bits can be coated with various materials to enhance their performance, durability, and efficiency. Here are some common coatings and their benefits:

1. **Titanium Nitride (TiN):**

- **Benefits:** Increases hardness and heat resistance, reducing friction and wear. Ideal for drilling in metal, wood, and plastic. Extends tool life significantly.

2. **Titanium Carbonitride (TiCN):**

- **Benefits:** Offers greater hardness and wear resistance than TiN. Suitable for drilling in harder materials like stainless steel and cast iron. Provides excellent abrasion resistance.

3. **Titanium Aluminum Nitride (TiAlN):**

- **Benefits:** Provides superior heat resistance and oxidation stability. Ideal for high-speed applications and dry machining. Extends tool life in high-temperature environments.

4. **Aluminum Titanium Nitride (AlTiN):**

- **Benefits:** Offers excellent thermal stability and oxidation resistance. Suitable for high-speed and high-temperature applications. Enhances performance in hard materials.

5. **Diamond Coating:**

- **Benefits:** Provides extreme hardness and wear resistance. Ideal for non-ferrous materials, composites, and abrasive materials. Extends tool life significantly in challenging applications.

6. **Black Oxide:**

- **Benefits:** Increases corrosion resistance and reduces friction. Provides a smoother finish and reduces chip welding. Suitable for general-purpose drilling.

7. **Zirconium Nitride (ZrN):**

- **Benefits:** Offers good wear resistance and reduced friction. Suitable for non-ferrous metals and plastics. Provides a smooth finish and extends tool life.

8. **Chrome Coating:**

- **Benefits:** Enhances corrosion resistance and surface hardness. Suitable for applications requiring a smooth finish. Provides moderate wear resistance.

These coatings improve the performance of drill bits by reducing friction, increasing hardness, and enhancing heat resistance, thereby extending the tool's lifespan and efficiency in various applications.