Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

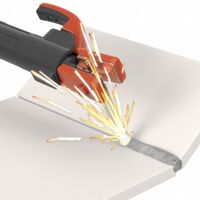

- Welding

.....Read More

Frequently Asked Questions

What is welding and how does it work?

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material (the weld pool) that cools to become a strong joint, though pressure can also be used, either alone or in combination with heat. The process works by creating an atomic bond between the materials, making the joined pieces act as a single unit. Different welding methods exist, such as arc welding, gas welding, and resistance welding, each suited for specific materials and applications.

What are the different types of welding?

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to form a strong joint.

There are many types of welding, each suited for different applications. Some common types include: * Shielded Metal Arc Welding (SMAW): Also known as "stick welding," it uses a consumable electrode coated in flux.

* Gas Metal Arc Welding (GMAW): Commonly called "MIG welding," it uses a continuous wire electrode and a shielding gas.

* Gas Tungsten Arc Welding (GTAW): Also known as "TIG welding," it uses a non-consumable tungsten electrode and an inert shielding gas.

* Flux-Cored Arc Welding (FCAW): Similar to MIG but uses a tubular electrode filled with flux.

* Submerged Arc Welding (SAW): Uses a continuously fed consumable electrode and a blanket of granular flux.

* Resistance Welding: Joins metals by applying pressure and passing a current through the metal.

What equipment do I need for welding?

For welding, essential equipment includes a welding machine (like MIG, TIG, or Stick welder), a welding helmet with an auto-darkening lens for eye protection, and welding gloves to shield hands from heat and sparks. You'll also need a welding jacket or flame-resistant clothing to protect your body. Depending on the type of welding, you might require consumables like welding wire or electrodes, shielding gas, and gas cylinders. A chipping hammer and wire brush are useful for cleaning welds, and clamps are necessary to secure your workpiece. Safety glasses and ear protection are also highly recommended for overall safety in the workshop.

How do I learn welding as a beginner?

Learning welding as a beginner involves several key steps. Start by researching the different welding processes, such as MIG, TIG, stick, and flux-cored, to understand their applications and complexities. Enroll in a reputable welding course or vocational program, as hands-on training and certified instruction are invaluable. Practice safety religiously by wearing appropriate personal protective equipment (PPE) like a welding helmet, gloves, and flame-resistant clothing. Begin with basic joints and techniques on scrap metal, focusing on maintaining consistent travel speed and arc length. Over time, you'll develop the muscle memory and precision required for quality welds.

What are the safety precautions for welding?

Welding requires strict safety precautions to prevent injuries. Always wear appropriate personal protective equipment (PPE), including a welding helmet with the correct shade lens, flame-resistant clothing, safety glasses, gloves, and sturdy work boots. Ensure adequate ventilation to avoid inhaling hazardous fumes. Keep a fire extinguisher readily available and clear the work area of flammable materials. Inspect equipment regularly for damage. Never weld near combustible liquids or gases. Ground the workpiece properly to prevent electrical shock. Be aware of hot metal and sparks, and allow welded materials to cool completely before handling.

What is the difference between MIG and TIG welding?

MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) are both arc welding processes, but they differ significantly. MIG welding uses a continuously fed wire electrode and a shielding gas, making it faster and easier for beginners. It's often used for thicker materials and production welding due to its speed and versatility. TIG welding, on the other hand, uses a non-consumable tungsten electrode and a separate filler rod, requiring more skill and precision. It produces cleaner, higher-quality welds, especially on thinner materials like stainless steel and aluminum, and is favored for aesthetic or critical applications.

How much does welding equipment cost?

The cost of welding equipment varies greatly depending on the type of welding process, brand, and features. Basic stick welders can start from a few hundred dollars, while advanced MIG or TIG welders with robust capabilities can easily run into thousands. Factors like duty cycle, power output, and included accessories all influence the price. Additionally, don't forget to factor in the cost of consumables like electrodes, wire, gas, and safety gear, which are ongoing expenses. It's best to research specific models and types of welders to get a more precise cost estimate based on your particular needs and budget.

What are the best welding techniques for beginners?

For beginners, MIG (Gas Metal Arc Welding) is often recommended due to its relative ease of use. It employs a continuous wire electrode and a shielding gas, simplifying the process and allowing for quicker learning. Stick welding (Shielded Metal Arc Welding) is another good starting point; it's versatile and can be done outdoors, but requires more dexterity to maintain an arc. TIG (Gas Tungsten Arc Welding) offers the highest quality welds but is more challenging and typically not ideal for absolute beginners. Focus on safety first with proper PPE, and practice consistently with any chosen method.

What materials can be welded together?

Many materials can be welded, with common categories including metals like steel, aluminum, copper, and brass. Each requires specific welding processes due to differing properties such as melting points and conductivity. Beyond metals, certain plastics and composites can also be joined through specialized welding techniques, which often involve heat and pressure to create a strong bond. The choice of material dictates the appropriate welding method, equipment, and filler material to achieve a durable and effective weld.

What are common welding defects and how to avoid them?

Common welding defects include porosity (gas bubbles), undercut (groove at the weld toe), incomplete fusion (unmelted base metal), and cracks (fractures in the weld or base metal).

To avoid them, ensure proper preparation, including cleaning materials and correct joint design. Use the right welding technique with appropriate current, voltage, travel speed, and electrode angle. Maintain good shielding gas coverage to prevent atmospheric contamination, and preheat/post-heat when necessary to control cooling rates and reduce stress. Regular equipment maintenance and welder training are also crucial for quality welds.