Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What is spot welding and how does it work?

Spot welding is a resistance welding process used to join two or more metal sheets together by applying pressure and heat to the weld area. The heat is generated by the resistance to the electric current passing through the metal sheets. This process is commonly used in the automotive and manufacturing industries for its efficiency and speed.

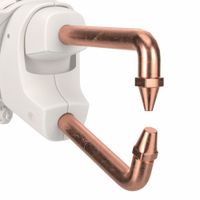

In spot welding, two copper alloy electrodes are positioned on opposite sides of the metal sheets to be joined. When the electrodes are brought together, they clamp the sheets tightly. An electric current is then passed through the electrodes, creating a high current density at the contact point. The resistance to this current flow generates heat, which melts the metal at the interface of the sheets. Once the desired temperature is reached, the current is stopped, and the molten metal cools and solidifies, forming a weld nugget that bonds the sheets together.

The key parameters in spot welding include the current magnitude, the duration of current flow (weld time), and the pressure applied by the electrodes. These parameters must be carefully controlled to ensure a strong and reliable weld without damaging the materials.

Spot welding is particularly effective for materials like low-carbon steel and aluminum, which have good electrical conductivity and thermal properties. It is favored for its speed, as it can produce welds in a fraction of a second, and for its ability to automate, making it ideal for high-volume production. However, it is generally limited to joining thin sheets and may not be suitable for thicker materials or complex geometries.

What materials can be spot welded?

Spot welding is a process primarily used for joining sheet metals. The materials that can be spot welded include:

1. **Low Carbon Steel**: This is the most common material for spot welding due to its excellent electrical conductivity and thermal properties.

2. **Stainless Steel**: Spot welding is feasible, though it requires more precise control due to its lower thermal conductivity and higher electrical resistance compared to low carbon steel.

3. **Aluminum**: While more challenging due to its high thermal conductivity and oxide layer, aluminum can be spot welded with proper equipment and techniques.

4. **Nickel Alloys**: These can be spot welded, but they require careful control of welding parameters due to their high electrical resistance.

5. **Copper and Copper Alloys**: Spot welding is possible, though challenging, due to copper's high thermal and electrical conductivity.

6. **Galvanized Steel**: This can be spot welded, but the zinc coating can cause issues like electrode wear and requires adjustments in welding parameters.

7. **Titanium**: Spot welding is possible, but it requires an inert atmosphere to prevent contamination and oxidation.

8. **High Strength Low Alloy Steels (HSLA)**: These can be spot welded, but require precise control to avoid issues like cracking.

9. **Magnesium Alloys**: These can be spot welded, though they require specific techniques due to their flammability and high thermal conductivity.

10. **Brass**: Spot welding is possible but challenging due to its high thermal conductivity and tendency to form brittle phases.

Each material requires specific considerations regarding electrode material, welding current, time, and pressure to ensure a strong weld without defects.

What are the advantages of spot welding over other welding methods?

Spot welding offers several advantages over other welding methods:

1. **Speed and Efficiency**: Spot welding is a rapid process, making it ideal for high-volume production environments. It can quickly join metal sheets without the need for additional materials like filler rods or flux.

2. **Cost-Effectiveness**: The process is economical due to its high speed and minimal labor requirements. It also reduces material costs since no additional consumables are needed.

3. **Automation Compatibility**: Spot welding is easily automated, which enhances consistency and precision in mass production settings, such as in the automotive industry.

4. **Minimal Distortion**: The localized heating in spot welding minimizes thermal distortion and warping of the workpieces, maintaining the integrity of the materials being joined.

5. **Energy Efficiency**: Spot welding uses electrical resistance to generate heat, which is a more energy-efficient process compared to other welding methods that require continuous heat sources.

6. **Strong Joints**: It produces strong, reliable joints, especially in thin metal sheets, which are commonly used in manufacturing industries.

7. **Clean Process**: Since it does not require flux or filler materials, spot welding results in cleaner joints with less post-weld cleaning required.

8. **Versatility**: It can be used on a variety of metals, including steel, stainless steel, and aluminum, making it versatile for different applications.

9. **Reduced Skill Requirement**: The process is relatively simple and requires less operator skill compared to other welding techniques, which can reduce training time and costs.

10. **Safety**: Spot welding is generally safer as it produces less smoke, fumes, and spatter compared to other welding methods, reducing health risks for operators.

How do you set up a spot welding machine?

To set up a spot welding machine, follow these steps:

1. **Safety Precautions**: Ensure you wear appropriate personal protective equipment (PPE) such as gloves, goggles, and protective clothing. Ensure the work area is clean and free from flammable materials.

2. **Machine Inspection**: Check the machine for any visible damage or wear. Ensure all components, including electrodes, cables, and connections, are in good condition.

3. **Power Supply**: Connect the machine to the appropriate power source. Ensure the voltage and current settings match the machine's requirements.

4. **Electrode Setup**: Install the correct type and size of electrodes for the material being welded. Ensure they are clean and properly aligned. Adjust the electrode force according to the material thickness and type.

5. **Cooling System**: If the machine has a cooling system, ensure it is filled with the appropriate coolant and functioning correctly to prevent overheating.

6. **Welding Parameters**: Set the welding parameters, including current, time, and pressure, based on the material specifications and thickness. Refer to the welding procedure specification (WPS) for guidance.

7. **Test Welds**: Perform test welds on scrap material to verify the settings. Inspect the welds for quality, ensuring proper penetration and strength.

8. **Adjustments**: Make necessary adjustments to the welding parameters based on the test results. Fine-tune the settings to achieve optimal weld quality.

9. **Production Welding**: Once satisfied with the test welds, proceed with the actual welding process. Continuously monitor the weld quality and make adjustments as needed.

10. **Maintenance**: Regularly maintain the machine by cleaning the electrodes, checking connections, and inspecting for wear and tear to ensure consistent performance.

By following these steps, you can effectively set up a spot welding machine for optimal performance and safety.

What are the common applications of spot welding?

Spot welding is widely used in various industries due to its efficiency and effectiveness in joining metal sheets. Here are some common applications:

1. **Automotive Industry**: Spot welding is extensively used in the automotive sector for assembling car bodies. It is ideal for joining steel sheets, which are commonly used in vehicle manufacturing. The process is fast and can be automated, making it suitable for high-volume production lines.

2. **Aerospace Industry**: In aerospace, spot welding is used for joining lightweight materials like aluminum and titanium. It is crucial for manufacturing components that require precision and strength without adding excessive weight.

3. **Electronics and Electrical Industry**: Spot welding is employed in the production of batteries, particularly in connecting battery cells. It is also used in manufacturing electrical components and appliances, where it provides reliable and durable joints.

4. **Construction Industry**: Spot welding is used in the construction of steel structures, such as bridges and buildings. It is effective for joining steel beams and reinforcing bars, ensuring structural integrity.

5. **Metal Furniture and Appliances**: The process is used in the production of metal furniture and household appliances, such as refrigerators and washing machines. It provides strong joints that can withstand regular use.

6. **Railway Industry**: Spot welding is applied in the manufacturing of railway components, including train carriages and tracks. It ensures the durability and safety of the components.

7. **HVAC Systems**: In heating, ventilation, and air conditioning systems, spot welding is used to join sheet metal ducts and components, ensuring airtight and robust connections.

Overall, spot welding is favored for its speed, cost-effectiveness, and ability to produce strong joints without the need for additional materials like solder or adhesives.

How do you maintain spot welding equipment?

To maintain spot welding equipment effectively, follow these steps:

1. **Regular Inspection**: Conduct daily visual inspections for wear and tear, loose connections, and any signs of damage. Check cables, hoses, and connectors for integrity.

2. **Electrode Maintenance**: Clean electrodes regularly to remove any build-up of material that can affect weld quality. Dress electrodes to maintain their shape and ensure proper contact. Replace electrodes when they become too worn.

3. **Cooling System**: Ensure the cooling system is functioning properly. Check for leaks and ensure that coolant levels are adequate. Clean filters and replace them as necessary to prevent overheating.

4. **Electrical Connections**: Tighten all electrical connections to prevent arcing and ensure efficient power transfer. Inspect for any signs of corrosion or damage.

5. **Lubrication**: Lubricate moving parts according to the manufacturer's recommendations to reduce friction and wear. Use appropriate lubricants for different components.

6. **Calibration**: Regularly calibrate the machine to ensure it operates within specified parameters. This includes checking the pressure settings, timing, and current levels.

7. **Software Updates**: Keep the control software updated to benefit from the latest features and improvements. This can also help in diagnosing issues more effectively.

8. **Safety Checks**: Ensure all safety features are operational, including emergency stops and guards. Train operators on safety protocols and the proper use of equipment.

9. **Record Keeping**: Maintain detailed records of maintenance activities, repairs, and parts replacements. This helps in tracking the equipment's performance and planning future maintenance.

10. **Professional Servicing**: Schedule regular professional servicing to address complex issues and ensure the equipment is in optimal condition.

By adhering to these maintenance practices, you can extend the lifespan of spot welding equipment, ensure consistent weld quality, and minimize downtime.

What are the safety precautions for spot welding?

1. **Personal Protective Equipment (PPE):** Wear appropriate PPE, including safety goggles, face shields, flame-resistant clothing, gloves, and steel-toed boots to protect against sparks, heat, and electrical hazards.

2. **Ventilation:** Ensure proper ventilation to avoid inhaling fumes and gases produced during the welding process. Use exhaust systems or fume extractors if necessary.

3. **Training and Certification:** Only trained and certified personnel should operate spot welding equipment. Regular training updates and safety drills are essential.

4. **Equipment Inspection:** Regularly inspect welding equipment for any signs of wear, damage, or malfunction. Ensure all connections are secure and that the machine is properly grounded.

5. **Electrical Safety:** Follow lockout/tagout procedures to ensure the machine is de-energized during maintenance. Be aware of electrical hazards and ensure all electrical components are insulated.

6. **Fire Safety:** Keep a fire extinguisher nearby and ensure the work area is free of flammable materials. Be aware of the potential for sparks to ignite nearby objects.

7. **Work Area Organization:** Maintain a clean and organized work area to prevent accidents. Ensure that tools and materials are stored properly and that pathways are clear.

8. **Proper Positioning:** Position yourself and the workpiece correctly to avoid strain and ensure stability during welding. Use clamps or fixtures to hold workpieces securely.

9. **Emergency Procedures:** Be familiar with emergency shutdown procedures and the location of emergency exits. Ensure that first aid kits are accessible.

10. **Communication:** Maintain clear communication with coworkers, especially in shared workspaces, to prevent accidents and ensure coordinated efforts.

11. **Machine Settings:** Use the correct machine settings for the materials being welded to prevent overheating or inadequate welds. Follow manufacturer guidelines for operation.

How do you troubleshoot spot welding defects?

To troubleshoot spot welding defects, follow these steps:

1. **Visual Inspection**: Examine the welds for common defects such as cracks, porosity, or inconsistent weld nugget size. Look for discoloration or burn marks indicating overheating.

2. **Check Equipment Settings**: Verify that the welding machine settings (current, pressure, and time) match the specifications for the materials being welded. Adjust as necessary.

3. **Electrode Condition**: Inspect electrodes for wear, misalignment, or contamination. Clean or replace electrodes if they are worn out or dirty.

4. **Material Preparation**: Ensure that the materials being welded are clean and free from contaminants like oil, rust, or paint, which can affect weld quality.

5. **Alignment and Fit-up**: Check that the workpieces are properly aligned and fit together without gaps. Misalignment can lead to weak welds.

6. **Cooling System**: Ensure the cooling system is functioning properly to prevent overheating, which can cause defects.

7. **Weld Schedule**: Review the weld schedule to ensure it is appropriate for the material thickness and type. Adjust the schedule if necessary.

8. **Mechanical Testing**: Perform destructive tests like peel or tensile tests to assess weld strength and quality.

9. **Non-Destructive Testing (NDT)**: Use methods like ultrasonic testing or X-ray inspection to detect internal defects without damaging the weld.

10. **Review Process Parameters**: Analyze data from previous successful welds to identify any deviations in the current process.

11. **Training and Skill**: Ensure operators are properly trained and understand the welding process and equipment.

12. **Consult Manufacturer Guidelines**: Refer to equipment and material manufacturer guidelines for troubleshooting tips specific to your setup.

By systematically addressing these areas, you can identify and rectify the root causes of spot welding defects.

What is the difference between spot welding and arc welding?

Spot welding and arc welding are both techniques used to join metals, but they differ in their processes, applications, and equipment.

Spot Welding:

- Spot welding is a type of resistance welding where heat is generated by passing a high current through the metal pieces to be joined, which are held together under pressure by electrodes.

- It is primarily used for joining sheet metals and is common in the automotive industry for assembling car bodies.

- The process involves clamping the metal pieces between two copper electrodes and applying a short burst of high current, which creates a weld at the contact point.

- Spot welding is efficient for mass production due to its speed and automation potential but is limited to overlapping joints and thin materials.

Arc Welding:

- Arc welding uses an electric arc to melt the base metals and filler material, if used, to form a weld.

- It is versatile and can be used on a wide range of materials and thicknesses, including steel, aluminum, and stainless steel.

- The process involves creating an arc between an electrode and the workpiece, which generates intense heat to melt the metals.

- Arc welding includes various methods such as Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW or MIG), and Tungsten Inert Gas Welding (TIG).

- It is suitable for both manual and automated operations and is used in construction, shipbuilding, and pipeline work.

In summary, spot welding is ideal for thin, overlapping sheets and high-volume production, while arc welding offers versatility for different materials and thicknesses, making it suitable for a broader range of applications.

How do you choose the right spot welding tips?

To choose the right spot welding tips, consider the following factors:

1. **Material Compatibility**: Match the tip material with the workpiece material. Common tip materials include copper, tungsten, and their alloys. Copper is suitable for aluminum and steel, while tungsten is used for high-resistance materials.

2. **Tip Geometry**: Select the appropriate tip shape based on the application. Dome-shaped tips are versatile, flat tips provide a larger contact area, and pointed tips are ideal for precision welding.

3. **Tip Size**: Choose the tip size according to the thickness of the materials being welded. Larger tips are better for thicker materials, while smaller tips are suitable for thin sheets.

4. **Cooling Requirements**: Ensure the tips have adequate cooling capabilities to prevent overheating. Water-cooled tips are preferred for high-volume production to maintain consistent performance.

5. **Current Capacity**: Verify that the tips can handle the required current without degradation. Higher current capacity is needed for thicker materials and larger welds.

6. **Durability and Wear Resistance**: Consider the tip's wear resistance, especially for high-volume or abrasive applications. Tungsten-copper alloys offer a good balance of conductivity and durability.

7. **Cost and Availability**: Balance the cost with performance needs. While high-quality tips may have a higher upfront cost, they often provide better longevity and weld quality.

8. **Manufacturer Recommendations**: Follow the equipment manufacturer's guidelines for tip selection to ensure compatibility and optimal performance.

9. **Application Specifics**: Consider any specific requirements of the welding application, such as accessibility, joint configuration, and production speed.

10. **Testing and Adjustment**: Conduct trial welds and adjust the tip selection based on weld quality, consistency, and efficiency.

By evaluating these factors, you can select the most suitable spot welding tips for your specific application, ensuring efficient and high-quality welds.