Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

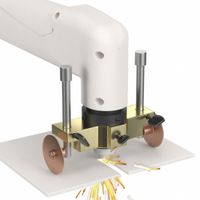

What is a plasma cutter and how does it work?

A plasma cutter is a tool used to cut through electrically conductive materials such as steel, stainless steel, aluminum, brass, and copper. It operates by utilizing a high-velocity jet of ionized gas, known as plasma, to melt and expel material from the cut.

The process begins when an electrical arc is generated between an electrode inside the cutter and the workpiece. This arc ionizes the gas (often compressed air, nitrogen, or oxygen) that is forced through a constricted opening, creating a focused plasma jet. The plasma reaches extremely high temperatures, often exceeding 20,000°C (36,000°F), which is sufficient to melt the metal being cut.

The high-speed plasma jet blows the molten metal away from the cut, resulting in a clean and precise cut. Plasma cutters can be manual or CNC (computer numerical control) operated, allowing for intricate and complex shapes to be cut with high precision.

Key components of a plasma cutter include the power supply, which provides the necessary energy to maintain the plasma arc; the arc starting console, which initiates the arc; and the torch, which directs the plasma jet.

Plasma cutting is favored for its speed, precision, and ability to cut through thick materials with minimal heat distortion. It is widely used in automotive repair, industrial construction, metal fabrication, and art.

What materials can a plasma cutter cut?

A plasma cutter is a versatile tool capable of cutting through a variety of conductive materials. It works by creating an electrical channel of superheated, electrically ionized gas (plasma) from the cutter through the workpiece, effectively melting the material and blowing it away. Here are the primary materials a plasma cutter can cut:

1. **Steel**: Plasma cutters can efficiently cut through different types of steel, including mild steel, carbon steel, and stainless steel. The thickness of the steel that can be cut depends on the power of the plasma cutter.

2. **Aluminum**: Due to its conductive properties, aluminum is easily cut by plasma cutters. This includes both pure aluminum and its alloys.

3. **Copper**: Although copper is a highly conductive material, plasma cutters can cut through it, though it may require more power and precision due to its thermal conductivity.

4. **Brass**: Similar to copper, brass can be cut with a plasma cutter, though it may present challenges due to its composition and thermal properties.

5. **Other Metals**: Plasma cutters can also cut through other conductive metals such as cast iron, titanium, and nickel alloys.

6. **Exotic Alloys**: Specialized plasma cutters can handle exotic and high-strength alloys used in aerospace and other advanced industries.

Plasma cutters are not suitable for cutting non-conductive materials such as wood, plastic, glass, or ceramics. The efficiency and quality of the cut depend on factors like the thickness of the material, the power of the plasma cutter, and the skill of the operator.

How thick can a plasma cutter cut?

The thickness a plasma cutter can cut depends on several factors, including the power of the machine, the type of material being cut, and the specific model of the plasma cutter. Generally, plasma cutters are categorized by their amperage, which directly influences their cutting capacity.

1. **Low-Amperage Plasma Cutters (20-40 Amps):** These are typically used for light-duty tasks and can cut materials up to about 1/4 inch (6 mm) thick. They are suitable for hobbyists or small-scale projects involving thin metals.

2. **Medium-Amperage Plasma Cutters (40-80 Amps):** These machines are more versatile and can handle thicker materials, generally up to 1/2 inch (12 mm) to 3/4 inch (19 mm) thick. They are commonly used in automotive repair, metal fabrication, and maintenance work.

3. **High-Amperage Plasma Cutters (80-200+ Amps):** Designed for heavy-duty industrial applications, these cutters can slice through materials up to 1 inch (25 mm) to 2 inches (50 mm) thick or more. They are used in industries such as shipbuilding, construction, and large-scale manufacturing.

4. **Specialized Industrial Plasma Cutters:** Some advanced models, particularly those used in CNC plasma cutting tables, can cut even thicker materials, sometimes exceeding 3 inches (75 mm), depending on the power source and technology used.

The cutting speed and quality also vary with thickness; thicker materials may require slower cutting speeds to maintain precision and reduce dross. Additionally, the type of metal (e.g., steel, aluminum, stainless steel) can affect the maximum thickness due to differences in conductivity and melting points.

What are the advantages of using a plasma cutter?

A plasma cutter offers several advantages, making it a popular choice for cutting metal and other conductive materials:

1. **Precision and Accuracy**: Plasma cutters provide high precision and clean cuts with minimal slag, reducing the need for secondary finishing processes. This precision is beneficial for intricate designs and detailed work.

2. **Speed**: Plasma cutting is significantly faster than traditional cutting methods like oxy-fuel cutting, especially for thinner materials. This efficiency can lead to increased productivity and reduced labor costs.

3. **Versatility**: Plasma cutters can cut a wide range of conductive materials, including steel, stainless steel, aluminum, brass, and copper. They can handle various thicknesses, making them suitable for diverse applications.

4. **Quality of Cut**: The high temperature of the plasma arc results in smooth, clean edges with minimal warping or distortion, enhancing the quality of the finished product.

5. **Ease of Use**: Modern plasma cutters are user-friendly, often featuring intuitive controls and automated settings. This ease of use reduces the learning curve and allows operators to achieve high-quality results with minimal training.

6. **Portability**: Many plasma cutters are compact and lightweight, making them easy to transport and ideal for on-site work or in workshops with limited space.

7. **Safety**: Plasma cutting is generally safer than oxy-fuel cutting as it does not require flammable gases. Additionally, the risk of metal warping is reduced due to the localized heat of the plasma arc.

8. **Cost-Effectiveness**: While the initial investment may be higher, the speed, efficiency, and reduced need for secondary processing can lead to long-term cost savings.

9. **Environmental Impact**: Plasma cutting produces fewer noxious gases and less waste compared to some other cutting methods, making it a more environmentally friendly option.

How do you choose the right plasma cutter for your needs?

To choose the right plasma cutter, consider the following factors:

1. **Material Type and Thickness**: Determine the types of metals you'll be cutting (e.g., steel, aluminum) and their maximum thickness. Choose a plasma cutter with sufficient amperage to cut through the thickest material you plan to work with.

2. **Cutting Speed**: Evaluate the cutting speed required for your projects. Higher amperage machines cut faster and more efficiently, which is crucial for high-volume work.

3. **Power Supply**: Check the power requirements. Some plasma cutters operate on 110V, while others require 220V. Ensure your workspace can accommodate the power needs.

4. **Portability**: If you need to move the cutter frequently, consider its weight and size. Portable models are lighter and more compact but may have lower power.

5. **Duty Cycle**: The duty cycle indicates how long a machine can operate continuously before needing a break. A higher duty cycle is essential for prolonged use.

6. **Air Supply**: Plasma cutters require compressed air. Some models have built-in compressors, while others need an external air supply. Consider the availability and cost of an air compressor if needed.

7. **Pilot Arc**: A pilot arc feature allows cutting without direct contact with the metal, useful for cutting rusty or painted surfaces.

8. **Budget**: Determine your budget, balancing cost with the features and performance you need. Higher-end models offer more power and features but at a higher price.

9. **Brand and Warranty**: Choose reputable brands known for quality and reliability. Check the warranty and customer support options.

10. **User Reviews and Recommendations**: Research user reviews and seek recommendations from professionals to gauge performance and reliability.

By assessing these factors, you can select a plasma cutter that meets your specific needs and ensures efficient and effective cutting performance.

What safety precautions should be taken when using a plasma cutter?

When using a plasma cutter, several safety precautions are essential to ensure a safe working environment:

1. **Personal Protective Equipment (PPE):** Wear appropriate PPE, including a welding helmet with a suitable shade, safety goggles, flame-resistant clothing, leather gloves, and steel-toed boots to protect against sparks, UV radiation, and hot metal.

2. **Ventilation:** Ensure adequate ventilation in the workspace to avoid inhaling harmful fumes and gases produced during cutting. Use exhaust systems or work in well-ventilated areas.

3. **Fire Safety:** Keep a fire extinguisher nearby and ensure the work area is free of flammable materials. Be aware of potential fire hazards and have a fire watch if necessary.

4. **Electrical Safety:** Inspect cables and connections for damage before use. Ensure the plasma cutter is properly grounded and avoid using it in wet conditions to prevent electric shock.

5. **Work Area:** Maintain a clean and organized workspace. Secure the workpiece to prevent movement during cutting, and ensure there is a stable surface to work on.

6. **Training and Familiarity:** Only trained and authorized personnel should operate a plasma cutter. Familiarize yourself with the equipment's operation manual and understand all controls and settings.

7. **Noise Protection:** Plasma cutting can be noisy, so use ear protection to prevent hearing damage.

8. **Gas Safety:** If using a gas-powered plasma cutter, ensure gas cylinders are secured and check for leaks. Follow proper procedures for handling and storing gases.

9. **Emergency Procedures:** Be aware of emergency shutdown procedures and have a first aid kit accessible. Know how to respond to accidents or injuries.

10. **Regular Maintenance:** Perform regular maintenance checks on the plasma cutter to ensure it is in good working condition and to prevent malfunctions.

By adhering to these safety precautions, the risk of accidents and injuries can be significantly reduced when using a plasma cutter.

How do you maintain and care for a plasma cutter?

To maintain and care for a plasma cutter, follow these steps:

1. **Regular Inspection**: Frequently check the torch for any signs of wear or damage. Inspect the consumables, such as the nozzle and electrode, for wear and replace them as needed to ensure optimal performance.

2. **Clean the Torch**: After each use, clean the torch to remove any metal dust or debris. Use a soft brush or compressed air to clean the inside of the torch head and the consumables.

3. **Check Connections**: Ensure all connections, including the power cable, ground clamp, and air supply, are secure and free from damage. Loose or damaged connections can affect performance and safety.

4. **Air Quality**: Use clean, dry air to prevent moisture and oil from contaminating the torch and consumables. Install an air filter or dryer in the air supply line to remove impurities.

5. **Coolant System**: If your plasma cutter has a water-cooled torch, regularly check the coolant level and quality. Replace the coolant as recommended by the manufacturer to prevent overheating.

6. **Proper Storage**: Store the plasma cutter in a clean, dry environment. Protect it from dust, moisture, and extreme temperatures to prolong its lifespan.

7. **Follow Manufacturer Guidelines**: Adhere to the maintenance schedule and guidelines provided in the user manual. This includes replacing consumables and parts at recommended intervals.

8. **Calibration and Settings**: Regularly check and adjust the machine settings, such as amperage and air pressure, to match the material and thickness being cut. Proper settings ensure efficient cutting and reduce wear on consumables.

9. **Training and Safety**: Ensure operators are trained in proper use and maintenance procedures. Follow all safety guidelines to prevent accidents and equipment damage.

By following these steps, you can ensure the longevity and efficiency of your plasma cutter.

What is the difference between a plasma cutter and a laser cutter?

A plasma cutter and a laser cutter are both tools used for cutting materials, but they operate using different technologies and are suited for different applications.

A plasma cutter uses a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials. The process involves sending an electric arc through a gas that is passing through a constricted opening. The gas can be oxygen, air, inert gases, or others, depending on the material being cut. Plasma cutters are typically used for cutting metals such as steel, stainless steel, aluminum, brass, and copper. They are known for their ability to cut thick materials quickly and are often used in industrial settings, automotive repair, and metal fabrication.

In contrast, a laser cutter uses a focused beam of light (laser) to cut or engrave materials. The laser beam is generated by stimulating lasing material with electrical discharges or lamps within a closed container. The beam is then focused through lenses to achieve high precision. Laser cutters can cut a wide range of materials, including metals, plastics, wood, glass, and textiles. They are known for their precision and ability to produce intricate designs, making them popular in industries such as manufacturing, electronics, and art.

Key differences include the type of materials they can cut, with plasma cutters being limited to conductive metals, while laser cutters can handle a broader range of materials. Plasma cutters are generally faster for thicker materials, whereas laser cutters offer higher precision and cleaner edges, especially for thinner materials. Additionally, laser cutters can also engrave, adding versatility to their functionality.

Can a plasma cutter cut non-metal materials?

No, a plasma cutter cannot effectively cut non-metal materials. Plasma cutters work by creating an electrical arc through a gas that is blown at high speed out of a nozzle. This process ionizes the gas, turning it into plasma, which is capable of conducting electricity. The plasma is extremely hot and is used to melt the metal being cut, while the high-speed gas blows the molten metal away, creating a cut.

The key requirement for a material to be cut by a plasma cutter is that it must be electrically conductive. Metals such as steel, stainless steel, aluminum, brass, and copper are conductive and can be cut using a plasma cutter. Non-metal materials like wood, plastic, glass, and ceramics are not electrically conductive, and therefore, a plasma cutter cannot be used to cut them.

Additionally, non-metal materials do not respond well to the intense heat generated by the plasma cutter. For instance, wood and plastic would burn or melt rather than being cleanly cut. Glass and ceramics might crack or shatter due to thermal shock from the rapid temperature change.

For cutting non-metal materials, other tools and methods are more appropriate. For example, a laser cutter can be used for precise cutting of plastics, wood, and some ceramics, while waterjet cutters can handle a wide range of materials, including metals, plastics, glass, and stone, without the thermal effects associated with plasma cutting.

How much does a plasma cutter cost?

The cost of a plasma cutter can vary widely based on several factors, including the brand, model, features, and intended use. Here is a general breakdown of the price ranges:

1. **Entry-Level Plasma Cutters**: These are typically suitable for hobbyists or light-duty work. They often have lower amperage and are designed for cutting thinner materials. Prices for entry-level models can range from $200 to $500.

2. **Mid-Range Plasma Cutters**: These are more powerful and versatile, suitable for small to medium-sized workshops. They can handle thicker materials and often come with additional features like pilot arc technology. Prices for mid-range models generally range from $500 to $1,500.

3. **High-End Plasma Cutters**: Designed for professional use, these machines offer high power, precision, and durability. They are capable of cutting through thick materials and are often used in industrial settings. High-end plasma cutters can cost anywhere from $1,500 to $5,000 or more.

4. **CNC Plasma Cutting Systems**: These are advanced systems used for automated cutting processes in industrial applications. They include a CNC machine integrated with a plasma cutter, and prices can start at around $10,000 and go up to $100,000 or more, depending on the complexity and capabilities of the system.

Additional costs to consider include consumables like electrodes and nozzles, which need regular replacement, and accessories such as air compressors, which are necessary for the operation of most plasma cutters. Warranty, customer support, and brand reputation can also influence the overall cost.