Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Welding

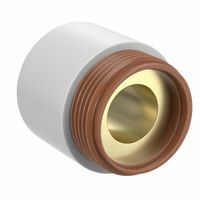

- Plasma Cutting

- Plasma Torch Consumables

.....Read More

Frequently Asked Questions

What are the main components of plasma torch consumables?

The main components of plasma torch consumables include:

1. **Electrode**: The electrode is typically made of copper with a tungsten insert. It conducts the electrical current from the power supply to the plasma arc. The tungsten insert withstands high temperatures and erosion, ensuring a stable arc.

2. **Nozzle (or Tip)**: The nozzle focuses the plasma arc and controls the flow of the plasma gas. It is usually made of copper and has a small orifice that shapes and constricts the plasma stream, enhancing cutting precision.

3. **Swirl Ring**: The swirl ring is designed to spin the plasma gas around the electrode, stabilizing the arc and improving cut quality. It is often made from heat-resistant materials like ceramic or high-temperature plastics.

4. **Shield Cap**: The shield cap protects the nozzle from molten metal and spatter during cutting. It also helps to control the flow of shielding gas, which protects the cut from oxidation and improves cut quality.

5. **Retaining Cap**: The retaining cap holds the other consumables in place within the torch. It ensures proper alignment and spacing of the components, which is crucial for optimal performance.

6. **Gas Diffuser**: The gas diffuser distributes the plasma gas evenly around the electrode and nozzle, ensuring consistent arc formation and stability.

These components work together to create and maintain the plasma arc, which is essential for efficient and precise cutting. Regular inspection and replacement of these consumables are necessary to maintain optimal performance and prolong the life of the plasma torch.

How often should plasma torch consumables be replaced?

The frequency of replacing plasma torch consumables depends on several factors, including the type of material being cut, the thickness of the material, the quality of the consumables, the amperage used, and the overall condition of the plasma cutting system. Generally, consumables should be inspected regularly and replaced as needed to maintain optimal cutting performance and quality.

1. **Electrode and Nozzle**: These are the most frequently replaced consumables. They should be replaced when there is noticeable wear, such as a pit in the electrode or an enlarged nozzle orifice. Typically, electrodes and nozzles can last anywhere from a few hours to several days of cutting, depending on usage and material.

2. **Swirl Ring**: This component directs the plasma gas flow and should be replaced if it shows signs of wear or damage. It usually lasts longer than electrodes and nozzles but should be checked regularly.

3. **Shield Cap**: The shield cap protects the nozzle and should be replaced if it becomes damaged or worn. Its lifespan is generally longer than that of the electrode and nozzle.

4. **Retaining Cap**: This holds the consumables in place and should be replaced if it shows signs of wear or damage.

To maximize consumable life, ensure proper setup and maintenance of the plasma cutting system, use the correct consumables for the material and thickness, and operate within the recommended parameters. Regular inspection and maintenance, such as cleaning the torch and checking for leaks, can also extend consumable life. Monitoring cut quality and listening for changes in the sound of the arc can help identify when consumables need replacement.

What factors affect the lifespan of plasma torch consumables?

Several factors influence the lifespan of plasma torch consumables:

1. **Cutting Parameters**: Incorrect settings for current, gas flow, and cutting speed can lead to premature wear. Optimal settings ensure efficient cutting and prolong consumable life.

2. **Material Type and Thickness**: Harder materials and thicker workpieces require more power, increasing wear on consumables. Adjusting settings to match material properties is crucial.

3. **Piercing Technique**: Improper piercing, such as piercing too close to the material, can cause molten metal to splash back onto the consumables, leading to damage.

4. **Torch-to-Work Distance**: Maintaining the correct standoff distance is essential. Too close can cause double arcing, while too far can lead to inefficient cutting and increased wear.

5. **Gas Quality and Type**: Impurities in the plasma gas can erode consumables. Using the correct type and quality of gas is vital for optimal performance.

6. **Cooling System**: Adequate cooling prevents overheating, which can degrade consumables. Ensuring the cooling system is functioning properly is important.

7. **Consumable Quality**: High-quality consumables are designed to withstand wear better than cheaper alternatives. Investing in quality can lead to longer lifespan and better performance.

8. **Maintenance and Handling**: Regular maintenance and careful handling prevent damage. Proper cleaning and storage of consumables can extend their life.

9. **Operator Skill**: Experienced operators are more likely to use the equipment correctly, reducing unnecessary wear on consumables.

10. **Machine Condition**: A well-maintained machine operates more efficiently, reducing stress on consumables. Regular checks and servicing are necessary to keep the machine in optimal condition.

How do I know when to replace my plasma torch consumables?

To determine when to replace your plasma torch consumables, monitor the following signs:

1. **Cut Quality Deterioration**: Noticeable decline in cut quality, such as increased dross, rough edges, or imprecise cuts, indicates worn consumables.

2. **Pierce Quality**: Difficulty in piercing or irregular pierce holes suggest the need for replacement.

3. **Visual Inspection**: Regularly inspect consumables for wear and tear. Look for signs like pitting, erosion, or deformation on the nozzle, electrode, and shield.

4. **Electrode Wear**: Check the electrode for a pit depth exceeding 1mm (0.04 inches). Excessive wear can lead to arc instability.

5. **Nozzle Wear**: Examine the nozzle orifice for roundness. An out-of-round or enlarged orifice affects arc precision and cut quality.

6. **Cutting Speed**: A decrease in cutting speed without changes in settings may indicate worn consumables.

7. **Arc Starting Issues**: Difficulty in starting the arc or frequent misfires can be a sign of worn electrodes or nozzles.

8. **Increased Gas Consumption**: If gas consumption rises unexpectedly, it may be due to worn consumables causing inefficient operation.

9. **Torch Standoff**: Inconsistent standoff distance during cutting can be a result of consumable wear.

10. **Regular Maintenance Schedule**: Follow a maintenance schedule based on manufacturer recommendations and your usage patterns to preemptively replace consumables.

By keeping an eye on these indicators, you can ensure optimal performance and longevity of your plasma cutting system.

What are the signs of worn-out plasma torch consumables?

Signs of worn-out plasma torch consumables include:

1. **Poor Cut Quality**: Deterioration in cut quality, such as rough edges, dross formation, and imprecise cuts, often indicates worn consumables.

2. **Increased Piercing Time**: Longer piercing times or failure to pierce through the material can signal that the consumables are no longer efficient.

3. **Inconsistent Arc**: An unstable or flickering arc suggests that the electrode or nozzle may be worn out, affecting the arc's stability.

4. **Nozzle Damage**: Visible damage to the nozzle, such as out-of-round or enlarged orifices, can lead to poor cut quality and should be replaced.

5. **Electrode Wear**: A pit or divot on the electrode's surface indicates wear. Excessive pitting can cause arc instability and should be addressed.

6. **Increased Gas Consumption**: If gas consumption rises without a change in cutting parameters, it may be due to worn consumables causing inefficient operation.

7. **Excessive Sparking**: More sparking than usual during cutting can be a sign of worn consumables, particularly the nozzle and electrode.

8. **Unusual Noises**: Strange noises during operation, such as hissing or popping, can indicate that consumables are not functioning properly.

9. **Frequent Tip-ups**: If the torch frequently tips up or fails to maintain a consistent distance from the workpiece, it may be due to worn consumables.

10. **Visual Inspection**: Regular visual checks can reveal signs of wear, such as discoloration, cracks, or deformation in the consumables.

11. **Increased Operating Costs**: A noticeable increase in operating costs, such as higher electricity or gas usage, can be a result of inefficient consumables.

12. **Shorter Consumable Life**: If consumables are wearing out faster than expected, it may indicate improper usage or the need for replacement.

How do I properly maintain my plasma torch consumables?

To properly maintain your plasma torch consumables, follow these steps:

1. **Regular Inspection**: Frequently inspect consumables for wear and tear. Look for signs of erosion, pitting, or any damage on the nozzle, electrode, and shield. Replace them if necessary to ensure optimal performance.

2. **Proper Installation**: Ensure consumables are installed correctly. Misalignment can lead to uneven wear and reduced lifespan. Follow the manufacturer's guidelines for installation.

3. **Correct Air Pressure**: Maintain the recommended air pressure. Too high or too low pressure can cause premature wear. Use a pressure gauge to monitor and adjust as needed.

4. **Cleanliness**: Keep consumables clean. Dirt and debris can cause arc instability and damage. Use a soft brush or cloth to clean them regularly.

5. **Cooling System Maintenance**: Ensure the cooling system is functioning properly. Overheating can damage consumables. Check coolant levels and clean filters regularly.

6. **Use Quality Consumables**: Invest in high-quality consumables. They may cost more initially but last longer and perform better, reducing overall costs.

7. **Avoid Overuse**: Do not exceed the duty cycle of the torch. Overuse can lead to overheating and damage. Allow the torch to cool down as recommended.

8. **Proper Storage**: Store consumables in a clean, dry place to prevent corrosion and contamination.

9. **Monitor Cutting Parameters**: Use the correct cutting parameters for the material and thickness. Incorrect settings can lead to excessive wear.

10. **Training and Documentation**: Ensure operators are trained in proper handling and maintenance procedures. Keep documentation of maintenance schedules and replacements.

By following these practices, you can extend the life of your plasma torch consumables and maintain efficient cutting performance.

What are the best practices for storing plasma torch consumables?

1. **Clean Environment**: Store consumables in a clean, dry area to prevent contamination from dust, dirt, and moisture, which can affect performance and lifespan.

2. **Temperature Control**: Maintain a stable temperature to avoid thermal expansion or contraction, which can lead to warping or damage.

3. **Humidity Control**: Use dehumidifiers or silica gel packs to keep humidity levels low, preventing corrosion and oxidation.

4. **Organized Storage**: Use labeled bins or drawers to organize consumables by type and size, ensuring easy access and inventory management.

5. **Original Packaging**: Keep consumables in their original packaging until use to protect them from environmental factors and maintain their integrity.

6. **Inventory Rotation**: Implement a first-in, first-out (FIFO) system to ensure older consumables are used before newer ones, reducing the risk of degradation over time.

7. **Regular Inspection**: Periodically inspect consumables for signs of wear, damage, or corrosion, and replace any that are compromised.

8. **Proper Handling**: Use gloves or clean hands when handling consumables to prevent oils and dirt from contaminating them.

9. **Documentation**: Maintain records of consumable usage and storage conditions to track performance and identify any issues related to storage practices.

10. **Training**: Educate staff on proper storage and handling procedures to ensure consistency and prevent mishandling.

11. **Secure Location**: Store consumables in a secure area to prevent unauthorized access and potential damage or loss.

12. **Avoid Overstocking**: Keep inventory levels manageable to reduce the risk of long-term storage issues and ensure consumables are used within their optimal lifespan.