- Home

- Power Transmission

.....Read More

Bearings

Belt & Chain Guides, Tensioners & Tighteners

Belts & Pulleys

Brakes, Clutches & Torque Limiters

Bushings

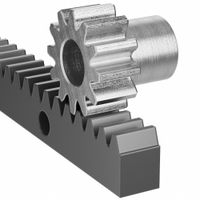

Gearing

Gearmotors

Linear Motion

Roller Chains & Sprockets

Rotary Shafts & Accessories

Rotary Shaft Sealing

Shaft Collars

Shaft Couplings & Universal Joints

Speed Reducers & Gearboxes

Spherical Rod Ends, Fixed Rod Ends, & Yoke Ends

Vibrators

Frequently Asked Questions

What are the main types of power transmission products?

How do rotary motion devices differ from linear motion devices?

What are the advantages of using belts and pulleys in power transmission?

How do gears function in power transmission systems?

What factors should be considered when selecting a chain for power transmission?

What role do bearings play in power transmission systems?

How do actuators contribute to linear motion in industrial applications?

What are the common materials used in manufacturing power transmission products?

How can the efficiency of a power transmission system be improved?

What maintenance practices are recommended for power transmission components?