Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

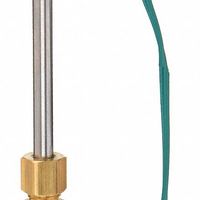

- Test Instruments

- Temperature And Environmental Measurement

- Temperature Probes Components

.....Read More

Frequently Asked Questions

What is the difference between thermocouples, RTDs, and thermistors?

Thermocouples, RTDs (Resistance Temperature Detectors), and thermistors are all temperature sensors, but they differ in their construction, operation, and applications.

**Thermocouples**: These are made of two different metals joined at one end, creating a junction. When this junction experiences a temperature change, it generates a voltage due to the Seebeck effect. The voltage is then measured and converted to temperature. Thermocouples are known for their wide temperature range, from -200°C to 1750°C, depending on the type. They are robust, inexpensive, and have a fast response time, making them suitable for industrial applications. However, they are less accurate than RTDs and thermistors, with typical accuracies of ±1°C to ±2°C.

**RTDs**: These sensors use the principle that the electrical resistance of a metal changes with temperature. RTDs are typically made from pure platinum, offering high accuracy and stability. They have a linear response over a temperature range of -200°C to 850°C. RTDs are more accurate than thermocouples, with typical accuracies of ±0.1°C to ±0.5°C, but they are more expensive and have a slower response time. They are ideal for precision applications in laboratories and industries where accuracy is critical.

**Thermistors**: These are made from ceramic materials that exhibit a large change in resistance with temperature. They are highly sensitive and provide excellent accuracy over a limited temperature range, typically -50°C to 150°C. Thermistors are less expensive than RTDs and are used in applications requiring precise temperature control, such as in household appliances and medical devices. However, they have a nonlinear response and are less suitable for high-temperature applications.

In summary, thermocouples are best for high-temperature and industrial applications, RTDs for precision and stability, and thermistors for sensitivity and cost-effectiveness in limited temperature ranges.

How do I choose the right temperature probe for my application?

1. **Application Requirements**: Determine the temperature range, accuracy, and response time needed for your application. Consider the environment (e.g., corrosive, high-pressure) and whether the probe will be in contact with liquids, gases, or solids.

2. **Probe Type**: Choose between thermocouples, RTDs (Resistance Temperature Detectors), thermistors, or infrared sensors. Thermocouples are suitable for wide temperature ranges and harsh environments. RTDs offer high accuracy and stability. Thermistors are ideal for precise measurements over a limited range. Infrared sensors are non-contact and useful for moving or inaccessible objects.

3. **Material Compatibility**: Ensure the probe material is compatible with the environment. Stainless steel is common for its corrosion resistance. For aggressive chemicals, consider Teflon or other specialized coatings.

4. **Size and Shape**: Select the appropriate probe size and shape for your installation. Consider immersion depth, mounting options, and space constraints.

5. **Response Time**: Choose a probe with a response time that matches your process dynamics. Smaller probes generally respond faster.

6. **Calibration and Accuracy**: Verify the probe’s calibration and accuracy specifications. Consider if recalibration is necessary and feasible for your application.

7. **Cost and Durability**: Balance cost with durability and performance. Higher initial costs may be justified by longer lifespan and reduced maintenance.

8. **Regulatory Compliance**: Ensure the probe meets any industry-specific standards or certifications required for your application.

9. **Supplier Support**: Choose a reputable supplier who offers technical support, warranty, and after-sales service.

10. **Integration**: Ensure compatibility with existing systems, including connectors and data acquisition equipment.

What are the advantages and disadvantages of using thermocouples?

Advantages of Thermocouples:

1. **Wide Temperature Range**: Thermocouples can measure a broad range of temperatures, from as low as -200°C to over 2000°C, depending on the type.

2. **Durability**: They are robust and can withstand harsh environments, including high pressure, vibration, and corrosive conditions.

3. **Fast Response Time**: Thermocouples have a quick response to temperature changes, making them suitable for dynamic processes.

4. **Simplicity and Size**: They are simple in design, compact, and can be easily integrated into various systems.

5. **Cost-Effective**: Generally, thermocouples are inexpensive compared to other temperature sensors, especially for high-temperature applications.

6. **Self-Powered**: They generate their own voltage and do not require an external power source.

Disadvantages of Thermocouples:

1. **Non-linear Output**: The voltage output is non-linear, requiring complex calibration and compensation for accurate readings.

2. **Low Sensitivity**: Thermocouples have lower sensitivity compared to other sensors like RTDs, which can affect precision in low-temperature applications.

3. **Reference Junction Compensation**: They require a reference junction compensation (cold junction compensation) to provide accurate measurements, adding complexity to the system.

4. **Drift**: Over time, thermocouples can drift due to oxidation or contamination, leading to inaccurate readings.

5. **Interference**: They are susceptible to electromagnetic interference, which can affect the accuracy of the measurements.

6. **Limited Accuracy**: While suitable for many applications, they are not as accurate as other temperature sensors like RTDs or thermistors, especially in critical applications requiring high precision.

How do I calibrate a temperature probe?

To calibrate a temperature probe, follow these steps:

1. **Gather Equipment**: Obtain a reference thermometer with a known accuracy, an ice bath, and a boiling water bath. Ensure the probe and reference thermometer are clean and dry.

2. **Ice Bath Calibration**:

- Fill a container with crushed ice and add distilled water to create a slushy mixture.

- Insert the temperature probe and the reference thermometer into the ice bath, ensuring they do not touch the sides or bottom of the container.

- Wait for the readings to stabilize. The probe should read 0°C (32°F). If not, note the deviation.

3. **Boiling Water Calibration**:

- Boil distilled water in a pot. Once boiling, insert the probe and reference thermometer, ensuring they are submerged but not touching the pot.

- Wait for the readings to stabilize. The probe should read 100°C (212°F) at sea level. Adjust for altitude if necessary, as boiling point decreases with elevation.

- Note any deviation from the expected reading.

4. **Adjust the Probe**:

- If the probe has an adjustable calibration feature, use the noted deviations to adjust the probe to match the reference thermometer.

- If the probe is non-adjustable, record the deviations for future reference and apply corrections manually when taking measurements.

5. **Documentation**:

- Record the calibration results, including the date, conditions, and any adjustments made.

- Regularly recalibrate the probe, especially if used frequently or in critical applications.

6. **Verification**:

- After adjustment, recheck the probe in both the ice bath and boiling water to ensure accuracy.

By following these steps, you ensure the temperature probe provides accurate readings, essential for precise temperature measurements.

What factors affect the accuracy of temperature probes?

Factors affecting the accuracy of temperature probes include:

1. **Calibration**: Regular calibration against a standard reference is crucial to maintain accuracy. Drift over time can lead to errors if not corrected.

2. **Probe Type**: Different types of probes (thermocouples, RTDs, thermistors) have varying levels of accuracy, sensitivity, and response times.

3. **Environmental Conditions**: Factors such as humidity, pressure, and electromagnetic interference can affect readings. Proper shielding and insulation can mitigate these effects.

4. **Installation**: Incorrect installation, such as improper immersion depth or contact with surfaces, can lead to inaccurate readings. Probes should be installed according to manufacturer guidelines.

5. **Response Time**: The time it takes for a probe to reach thermal equilibrium with its environment can affect accuracy, especially in rapidly changing conditions.

6. **Aging and Wear**: Over time, materials can degrade, affecting the probe's performance. Regular maintenance and replacement are necessary to ensure accuracy.

7. **Self-Heating**: Some probes, especially those with electrical components, can generate heat, affecting the measurement. Minimizing current flow can reduce this effect.

8. **Lead Wire Resistance**: In long cable runs, resistance in the lead wires can introduce errors, particularly in thermocouples. Using appropriate wire gauges and compensating for resistance can help.

9. **Thermal Conductivity**: The material and design of the probe can affect how quickly and accurately it responds to temperature changes.

10. **Signal Conditioning**: The quality of the signal processing equipment, including amplifiers and analog-to-digital converters, can impact the accuracy of the temperature reading.

11. **Hysteresis**: Some probes may exhibit hysteresis, where the path of temperature change affects the reading. This should be minimized through design and material choice.

12. **Chemical Exposure**: Exposure to corrosive or reactive chemicals can degrade probe materials, affecting accuracy. Using appropriate protective coatings can help.

How do I install a temperature probe correctly?

1. **Select the Right Probe**: Choose a temperature probe suitable for your application, considering factors like temperature range, environment, and compatibility with your device.

2. **Read the Manual**: Refer to the manufacturer's instructions for specific installation guidelines and safety precautions.

3. **Prepare the Installation Site**: Ensure the area is clean and free from obstructions. If necessary, drill a hole or prepare a mounting point for the probe.

4. **Position the Probe**: Place the probe in a location that accurately represents the temperature of the area or object you are monitoring. Avoid areas with direct sunlight, drafts, or heat sources unless these are the conditions you wish to measure.

5. **Secure the Probe**: Use appropriate mounting hardware, such as brackets, clamps, or adhesive, to secure the probe. Ensure it is stable and not subject to movement or vibration.

6. **Connect the Probe**: Attach the probe to the monitoring device or control system. This may involve connecting wires to terminals or plugging the probe into a designated port.

7. **Seal and Insulate**: If the probe is exposed to harsh environments, use sealants or protective covers to prevent damage. Insulate the probe if necessary to avoid heat loss or gain from the surroundings.

8. **Calibrate the Probe**: Follow the manufacturer's instructions to calibrate the probe, ensuring accurate readings. This may involve comparing the probe's readings to a known standard and adjusting as needed.

9. **Test the Installation**: Verify the probe is functioning correctly by checking the readings against expected values. Make adjustments if necessary.

10. **Regular Maintenance**: Periodically inspect and recalibrate the probe to maintain accuracy and ensure it remains in good working condition.

What maintenance is required for temperature probes?

Temperature probes require regular maintenance to ensure accurate and reliable measurements. Key maintenance tasks include:

1. **Calibration**: Regular calibration is essential to maintain accuracy. This involves comparing the probe's readings with a known standard and adjusting as necessary. Calibration frequency depends on the probe's usage and manufacturer recommendations.

2. **Cleaning**: Probes should be cleaned regularly to prevent contamination that can affect readings. Use appropriate cleaning agents that do not damage the probe material. For food industry applications, ensure compliance with hygiene standards.

3. **Inspection**: Regularly inspect probes for physical damage, such as cracks, corrosion, or wear. Check the integrity of the probe's cable and connectors, as damaged components can lead to inaccurate readings or failure.

4. **Testing**: Perform functional tests to ensure the probe responds correctly to temperature changes. This can involve immersing the probe in a controlled temperature environment and verifying the readings.

5. **Storage**: Store probes properly when not in use. Avoid extreme temperatures, humidity, and mechanical stress. Use protective covers or cases to prevent physical damage.

6. **Documentation**: Maintain records of calibration, cleaning, and any maintenance performed. This helps track the probe's performance over time and ensures compliance with industry standards.

7. **Replacement**: Replace probes that consistently provide inaccurate readings or show signs of significant wear and tear. Follow manufacturer guidelines for the expected lifespan of the probe.

By adhering to these maintenance practices, temperature probes can provide reliable and accurate measurements, ensuring the efficiency and safety of processes that depend on precise temperature monitoring.