Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Test Instruments

- Temperature And Environmental Measurement

- Temperature Probes Components

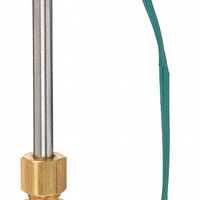

- High Accuracy Thermistor Probes

.....Read More

Frequently Asked Questions

What is a high-accuracy thermistor probe?

A high-accuracy thermistor probe is a temperature-sensing device that utilizes a thermistor, a type of resistor whose resistance varies significantly with temperature. These probes are designed to provide precise temperature measurements, often with an accuracy of ±0.1°C or better.

Thermistors are typically made from ceramic materials, such as metal oxides, that exhibit a predictable change in resistance with temperature. There are two main types: Negative Temperature Coefficient (NTC) thermistors, which decrease in resistance as temperature increases, and Positive Temperature Coefficient (PTC) thermistors, which increase in resistance with rising temperature. High-accuracy thermistor probes usually employ NTC thermistors due to their higher sensitivity and better linearity over a specific temperature range.

The probe consists of the thermistor element housed in a protective sheath, often made of stainless steel or other durable materials, to ensure stability and protection from environmental factors. The probe may also include a cable for connecting to a temperature measurement device or data logger.

High-accuracy thermistor probes are used in applications where precise temperature monitoring is critical, such as in medical devices, laboratory equipment, environmental monitoring, and industrial processes. They are favored for their rapid response time, high sensitivity, and ability to provide stable and repeatable measurements.

Calibration is essential for maintaining the accuracy of these probes. They are often calibrated against a known temperature standard to ensure their readings remain precise over time. Additionally, high-accuracy thermistor probes may include features like interchangeable elements, which allow for easy replacement without recalibration, and digital interfaces for integration with modern data acquisition systems.

How do thermistor probes measure temperature?

Thermistor probes measure temperature by utilizing the temperature-dependent resistance properties of thermistors, which are semiconductor devices. A thermistor is made from a mixture of metal oxides, such as manganese, nickel, or cobalt, which are sintered to form a ceramic-like material. There are two main types of thermistors: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC). NTC thermistors decrease in resistance as temperature increases, while PTC thermistors increase in resistance with rising temperature.

When a thermistor probe is exposed to a temperature change, the resistance of the thermistor changes accordingly. This change in resistance is measured by passing a small, constant current through the thermistor and measuring the resulting voltage drop across it. The voltage drop is directly related to the resistance, which can be calculated using Ohm's Law (V = IR, where V is voltage, I is current, and R is resistance).

The resistance value is then converted into a temperature reading using a calibration curve or a mathematical equation specific to the thermistor's material properties. This relationship is often non-linear, so precise temperature measurement requires accurate calibration and sometimes the use of linearization techniques or lookup tables.

Thermistor probes are valued for their high sensitivity, fast response time, and accuracy over a limited temperature range. They are commonly used in applications such as medical devices, environmental monitoring, and consumer electronics. However, their non-linear response and limited temperature range compared to other sensors like thermocouples or RTDs can be a limitation in some applications.

What are the advantages of using thermistor probes over other types of probes?

Thermistor probes offer several advantages over other types of temperature probes:

1. **High Sensitivity**: Thermistors have a high temperature coefficient of resistance, making them extremely sensitive to small temperature changes. This allows for precise temperature measurements.

2. **Accuracy**: They provide accurate readings over a limited temperature range, which is ideal for applications requiring precise temperature control.

3. **Fast Response Time**: Due to their small size and low thermal mass, thermistors can quickly respond to temperature changes, making them suitable for dynamic temperature monitoring.

4. **Cost-Effectiveness**: Thermistors are generally less expensive than other types of temperature sensors, such as RTDs (Resistance Temperature Detectors) and thermocouples, making them a cost-effective choice for many applications.

5. **Compact Size**: Their small size allows for easy integration into compact devices and systems, which is beneficial in applications with space constraints.

6. **Durability**: Thermistors are robust and can withstand mechanical stress and harsh environmental conditions, enhancing their longevity and reliability.

7. **Wide Range of Applications**: They are versatile and can be used in various applications, including medical devices, automotive systems, and consumer electronics.

8. **Simple Circuitry**: The electrical circuitry required to use thermistors is relatively simple, which can reduce the complexity and cost of the overall system.

9. **Non-linearity**: While often seen as a disadvantage, the non-linear resistance-temperature relationship of thermistors can be beneficial in certain applications where non-linear response is desired.

10. **Self-Heating**: Thermistors can self-heat when a current passes through them, which can be used advantageously in some applications to maintain a constant temperature.

These advantages make thermistor probes a preferred choice in many scenarios where precise, rapid, and cost-effective temperature measurement is required.

What is the difference between threaded and flex-wire thermistor probes?

Threaded thermistor probes and flex-wire thermistor probes differ primarily in their design and application.

Threaded thermistor probes are designed with a threaded fitting, allowing them to be securely mounted into equipment or systems. This design is ideal for applications requiring stable and fixed positioning, such as in industrial processes or HVAC systems. The threaded design ensures a tight seal, which can be crucial for maintaining system integrity and preventing leaks in pressurized environments. These probes are typically more robust and can withstand harsher conditions, making them suitable for environments where durability is essential.

Flex-wire thermistor probes, on the other hand, feature flexible leads or wires, allowing for more versatile placement and easier integration into systems where space is limited or where the probe needs to be maneuvered into position. This flexibility makes them ideal for applications requiring frequent repositioning or where the probe needs to be inserted into hard-to-reach areas. Flex-wire probes are often used in laboratory settings, consumer electronics, or any application where ease of installation and adaptability are prioritized.

In summary, the main differences lie in their mounting and application suitability: threaded probes offer secure, fixed installation for industrial use, while flex-wire probes provide flexibility and ease of use for more adaptable applications.

How do you install a flange-mounted thermistor probe?

1. **Select Location**: Choose an appropriate location for the thermistor probe where it can accurately measure the desired temperature. Ensure the area is free from obstructions and provides good thermal contact.

2. **Prepare Surface**: Clean the mounting surface to remove any dirt, grease, or debris. This ensures proper contact and accurate temperature readings.

3. **Drill Hole**: If necessary, drill a hole in the mounting surface to accommodate the probe. The hole should match the diameter of the probe for a snug fit.

4. **Position Flange**: Align the flange of the thermistor probe with the pre-drilled holes on the mounting surface. Ensure the probe is positioned correctly for optimal temperature measurement.

5. **Secure Flange**: Use appropriate fasteners (e.g., screws or bolts) to secure the flange to the mounting surface. Tighten them evenly to avoid any stress on the probe.

6. **Seal Joints**: Apply a suitable sealant or gasket between the flange and the mounting surface to prevent any air or fluid leaks, which could affect temperature readings.

7. **Connect Wiring**: Connect the thermistor probe's wiring to the monitoring system or control unit. Ensure proper electrical connections and insulation to prevent short circuits.

8. **Test Installation**: Power on the system and verify that the thermistor probe is functioning correctly. Check for accurate temperature readings and ensure there are no leaks or loose connections.

9. **Calibration**: If necessary, calibrate the thermistor probe according to the manufacturer's instructions to ensure precise temperature measurements.

10. **Documentation**: Record the installation details, including location, date, and any calibration data, for future reference and maintenance.

By following these steps, you can ensure a proper and effective installation of a flange-mounted thermistor probe.

What applications are handheld thermistor probes best suited for?

Handheld thermistor probes are best suited for applications requiring precise temperature measurements in a portable and convenient format. They are commonly used in the following scenarios:

1. **Food Safety and Quality Control**: In the food industry, handheld thermistor probes are used to monitor the temperature of perishable goods during storage, transportation, and preparation to ensure compliance with safety standards and prevent spoilage.

2. **HVAC Systems**: Technicians use these probes to measure air and surface temperatures in heating, ventilation, and air conditioning systems to ensure optimal performance and energy efficiency.

3. **Medical and Laboratory Settings**: In medical environments, thermistor probes are used to measure body temperature or the temperature of samples and reagents in laboratories, ensuring accurate and reliable results.

4. **Industrial Processes**: They are employed in various industrial applications to monitor the temperature of machinery, equipment, and processes, helping to maintain operational efficiency and prevent overheating or damage.

5. **Environmental Monitoring**: Handheld thermistor probes are used in environmental studies to measure soil, water, and air temperatures, providing critical data for research and analysis.

6. **Electronics Testing**: In electronics, these probes help in testing and troubleshooting by measuring the temperature of components and circuits, ensuring they operate within safe limits.

7. **Research and Development**: Scientists and engineers use thermistor probes in R&D to gather precise temperature data for experiments and product development.

8. **Automotive Industry**: They are used to check engine and component temperatures, aiding in diagnostics and maintenance.

Overall, handheld thermistor probes are valued for their accuracy, ease of use, and versatility across various fields where temperature monitoring is crucial.

How do strap-mounted thermistor probes work?

Strap-mounted thermistor probes work by utilizing the temperature-sensitive resistance properties of thermistors, which are semiconductor devices. These probes are designed to be attached to the surface of pipes or other cylindrical objects using a strap, allowing them to measure the surface temperature indirectly.

The thermistor itself is typically made from a ceramic or polymer material that exhibits a significant change in resistance with temperature variations. There are two main types of thermistors: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC). NTC thermistors decrease in resistance as temperature increases, while PTC thermistors increase in resistance with rising temperature. NTC thermistors are more commonly used in strap-mounted probes.

When the strap-mounted thermistor probe is secured to a pipe, it comes into thermal equilibrium with the pipe's surface. As the temperature of the pipe changes, the thermistor's resistance changes correspondingly. This change in resistance is measured by a connected electronic circuit, often a Wheatstone bridge or a simple voltage divider, which converts the resistance change into a readable electrical signal, typically a voltage or current.

The electronic circuit is usually calibrated to correlate specific resistance values to temperature readings, allowing for accurate temperature monitoring. The strap ensures good thermal contact between the thermistor and the pipe, minimizing the effects of ambient temperature and ensuring that the thermistor accurately reflects the pipe's temperature.

Strap-mounted thermistor probes are widely used in HVAC systems, industrial processes, and other applications where non-invasive temperature measurement is required. They offer advantages such as ease of installation, cost-effectiveness, and the ability to measure temperature without penetrating the pipe or vessel.