- Home

- Test Instruments

- Temperature And Environmental Measurement

.....Read More

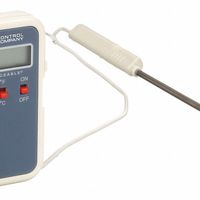

Benchtop & Handheld Temperature Meters

Clip-On & Pocket Thermometers

Controlled Critical Environment Thermometers & Monitoring

Digital Temperature & Humidity Switches

Environmental Measurement

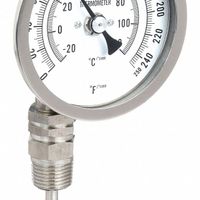

Fixed-Location Thermometers & Thermowells

Infrared Temperature Measurement

Liquid-in-Glass & Laboratory Thermometers

Temperature Calibrators

Temperature & Humidity Transmitters

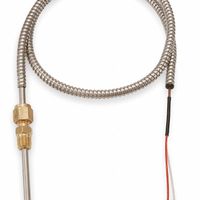

Temperature Probes & Components

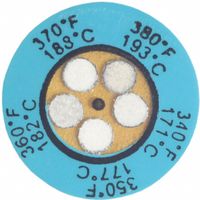

Temperature Strips & Dots

Frequently Asked Questions

What are the best devices for measuring humidity and temperature?

How do infrared temperature measurement devices work?

What is the difference between fixed-location thermometers and portable thermometers?

How accurate are liquid-in-glass thermometers compared to digital ones?

What are the benefits of using temperature probes and components?

How do environmental measurement products track changes in pressure?

What are the applications of controlled critical environment thermometers?

How do you calibrate benchtop and handheld temperature meters?

What factors should be considered when choosing a thermometer for industrial use?

How do clip-on and pocket thermometers differ in functionality?