Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Test Instruments

- Temperature And Environmental Measurement

- Temperature Probes Components

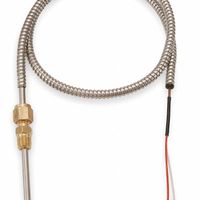

- Wide Application Thermocouple Probes

.....Read More

Frequently Asked Questions

What is a thermocouple probe and how does it work?

A thermocouple probe is a temperature measurement device consisting of two dissimilar metal wires joined at one end, forming a junction. This junction is exposed to the temperature to be measured, while the other ends of the wires are connected to a measurement device. The principle behind its operation is the Seebeck effect, which states that a voltage (thermoelectric EMF) is generated when there is a temperature difference between the junction and the other ends of the wires.

The two metals used in a thermocouple are selected based on their thermoelectric properties and the temperature range they can measure. Common types include Type K (Nickel-Chromium/Nickel-Alumel), Type J (Iron/Constantan), and Type T (Copper/Constantan), each suitable for different temperature ranges and environments.

When the junction is heated or cooled, a voltage is produced that is proportional to the temperature difference between the junction and the reference ends. This voltage is then interpreted by a thermocouple thermometer or a data acquisition system, which converts it into a temperature reading using standard thermocouple reference tables.

Thermocouple probes are valued for their wide temperature range, durability, and fast response time. They are used in various applications, from industrial processes to scientific research, due to their ability to measure extreme temperatures and their robustness in harsh environments. However, they require proper calibration and compensation for accurate readings, as the voltage output is influenced by the reference junction temperature and the specific characteristics of the metals used.

What are the different types of thermocouple probes?

Thermocouple probes come in various types, each suited for specific applications and environments. The main types include:

1. **Type K (Chromel-Alumel):** Widely used due to its wide temperature range (-200°C to 1260°C) and good oxidation resistance. Suitable for general-purpose applications.

2. **Type J (Iron-Constantan):** Suitable for temperatures ranging from -40°C to 750°C. It is cost-effective and commonly used in older equipment.

3. **Type T (Copper-Constantan):** Ideal for low-temperature applications (-200°C to 350°C) and offers good accuracy and stability.

4. **Type E (Chromel-Constantan):** Offers a high output (68 µV/°C) and is suitable for cryogenic applications due to its range (-200°C to 900°C).

5. **Type N (Nicrosil-Nisil):** Designed for high-temperature stability and oxidation resistance, with a range of -200°C to 1300°C. It is often used in the petrochemical industry.

6. **Type S (Platinum-Rhodium):** Used for high-temperature applications up to 1600°C, such as in the glass and metal industries. It is highly stable but expensive.

7. **Type R (Platinum-Rhodium):** Similar to Type S but with a slightly higher temperature range, up to 1600°C. It is also used in high-temperature applications.

8. **Type B (Platinum-Rhodium):** Suitable for extremely high temperatures, up to 1700°C. It is used in high-temperature research and industrial processes.

9. **Type C (Tungsten-Rhenium):** Used for very high temperatures, up to 2315°C, in inert or vacuum environments, such as in aerospace applications.

10. **Type M (Nickel-Molybdenum/Nickel-Cobalt):** Used in vacuum furnaces with a range of 0°C to 1400°C.

Each type of thermocouple probe is selected based on factors like temperature range, environment, accuracy, and cost, ensuring optimal performance for specific applications.

How do you choose the right thermocouple probe for an application?

1. **Temperature Range**: Select a thermocouple type that can handle the specific temperature range of your application. For example, Type K is suitable for -200°C to 1260°C, while Type R is better for high temperatures up to 1600°C.

2. **Environment**: Consider the environment where the thermocouple will be used. For corrosive or oxidizing environments, choose materials like Inconel or stainless steel. For vacuum or inert environments, a less robust material may suffice.

3. **Accuracy and Sensitivity**: Different thermocouple types offer varying levels of accuracy and sensitivity. Type T is known for high accuracy at low temperatures, while Type S is used for high precision at elevated temperatures.

4. **Response Time**: The probe's diameter and construction affect response time. Thinner probes respond faster but may be less durable. Choose based on the required speed of temperature measurement.

5. **Durability and Longevity**: Consider the mechanical strength and wear resistance needed. For harsh conditions, a robust sheath material like stainless steel or ceramic may be necessary.

6. **Installation Requirements**: Ensure the probe's size and shape fit the installation site. Consider whether a flexible or rigid probe is needed and the type of mounting or fitting required.

7. **Cost**: Balance the cost with performance needs. More durable and accurate thermocouples may be more expensive but offer better long-term value.

8. **Regulatory and Industry Standards**: Ensure compliance with any relevant standards or regulations specific to your industry or application.

9. **Interference and Noise**: For environments with electrical interference, consider using shielded cables or twisted pair wires to minimize noise.

10. **Calibration and Maintenance**: Consider ease of calibration and maintenance. Some applications may require frequent recalibration to maintain accuracy.

What are the advantages of using thermocouple probes over other temperature sensors?

Thermocouple probes offer several advantages over other temperature sensors:

1. **Wide Temperature Range**: Thermocouples can measure a broad range of temperatures, from as low as -200°C to as high as 2500°C, depending on the type. This makes them suitable for various industrial applications.

2. **Fast Response Time**: Due to their small size and low thermal mass, thermocouples can quickly respond to temperature changes, which is crucial in dynamic environments.

3. **Durability and Robustness**: Thermocouples are rugged and can withstand harsh conditions, including high pressure, vibration, and corrosive environments, making them ideal for industrial settings.

4. **Simplicity and Cost-Effectiveness**: They are relatively simple in design and inexpensive compared to other temperature sensors, such as RTDs and thermistors, especially for high-temperature applications.

5. **Self-Powered**: Thermocouples generate a voltage directly from the temperature difference between their junctions, eliminating the need for an external power source.

6. **Versatility**: Available in various types (e.g., Type K, J, T, E), thermocouples can be selected based on specific temperature ranges and environmental conditions.

7. **Compact Size**: Their small size allows for easy integration into systems where space is limited.

8. **Long Distance Transmission**: Thermocouples can transmit signals over long distances with minimal signal degradation, especially when using appropriate extension wires.

9. **Interchangeability**: Standardized thermocouple types allow for easy replacement and interchangeability without significant recalibration.

10. **Non-Contact Measurement**: Some thermocouple designs can measure temperature without direct contact, useful in applications where contamination or interference must be avoided.

These advantages make thermocouples a preferred choice in many industrial, scientific, and commercial applications where reliable and accurate temperature measurement is essential.

How do you install and maintain thermocouple probes?

To install thermocouple probes, first select the appropriate type and size for your application. Ensure the thermocouple is compatible with the temperature range and environment. Begin by identifying the measurement point and prepare the surface, ensuring it is clean and free of contaminants. Drill a hole if necessary, matching the probe's diameter. Insert the thermocouple probe into the hole or attach it to the surface using clamps, brackets, or adhesive, ensuring good thermal contact. Connect the thermocouple wires to the corresponding terminals on the temperature measurement device, observing polarity (red is negative, and the other color is positive). Use extension wires if needed, ensuring they are of the same thermocouple type.

For maintenance, regularly inspect the thermocouple for signs of wear, corrosion, or damage. Check the insulation and connections for integrity. Calibrate the thermocouple periodically to ensure accuracy, using a reference thermometer or calibration equipment. Replace the thermocouple if it shows signs of drift or damage. Keep the installation area clean and free from contaminants that could affect readings. Store spare thermocouples properly to prevent damage.

What are the common applications of thermocouple probes?

Thermocouple probes are widely used for temperature measurement across various industries due to their versatility, durability, and wide temperature range. Common applications include:

1. **Industrial Processes**: Thermocouples are essential in monitoring and controlling temperatures in manufacturing processes such as metal processing, glass production, and chemical manufacturing. They ensure optimal conditions for product quality and safety.

2. **HVAC Systems**: In heating, ventilation, and air conditioning systems, thermocouples help regulate and maintain desired temperatures, ensuring energy efficiency and comfort.

3. **Automotive Industry**: Used in engine testing and exhaust systems, thermocouples measure temperatures to optimize performance and reduce emissions.

4. **Aerospace**: Thermocouples are critical in testing and monitoring aircraft engines and components, ensuring safety and performance under extreme conditions.

5. **Food and Beverage**: In food processing and storage, thermocouples ensure that products are cooked, stored, and transported at safe temperatures, preventing spoilage and contamination.

6. **Medical Equipment**: Thermocouples are used in medical devices like incubators and sterilizers to maintain precise temperature control, crucial for patient safety and equipment efficacy.

7. **Research and Development**: In laboratories, thermocouples are used for experiments requiring precise temperature measurements, such as material testing and chemical reactions.

8. **Energy Sector**: In power plants, thermocouples monitor temperatures in boilers, turbines, and reactors, ensuring efficient energy production and safety.

9. **Consumer Appliances**: Common in household appliances like ovens, water heaters, and refrigerators, thermocouples help maintain desired temperatures for user convenience and safety.

10. **Environmental Monitoring**: Used in weather stations and environmental studies, thermocouples measure atmospheric and water temperatures, contributing to climate research and environmental protection efforts.

How do you troubleshoot issues with thermocouple probes?

1. **Visual Inspection**: Check for physical damage, corrosion, or loose connections. Ensure the probe is properly inserted and secured.

2. **Check Connections**: Verify that all connections are tight and free from corrosion. Ensure the correct polarity is maintained.

3. **Measure Continuity**: Use a multimeter to check for continuity in the thermocouple circuit. A lack of continuity indicates a broken wire.

4. **Verify Calibration**: Ensure the thermocouple is calibrated correctly. Compare readings with a known temperature source.

5. **Check for Interference**: Ensure there is no electromagnetic interference from nearby equipment. Use shielded cables if necessary.

6. **Inspect Insulation**: Check the insulation for wear or damage, which can cause short circuits or inaccurate readings.

7. **Test with a Known Good Thermocouple**: Replace the suspect thermocouple with a known good one to see if the issue persists.

8. **Check the Cold Junction Compensation**: Ensure the cold junction compensation is functioning correctly, as errors here can lead to inaccurate readings.

9. **Examine the Environment**: Ensure the thermocouple is suitable for the environment, considering factors like temperature range and chemical exposure.

10. **Review the Instrumentation**: Check the connected instrumentation for faults or incorrect settings.

11. **Check for Ground Loops**: Ensure there are no ground loops, which can cause erroneous readings.

12. **Inspect the Extension Wire**: Ensure the extension wire is of the same type as the thermocouple and is in good condition.

13. **Temperature Range**: Verify that the thermocouple is being used within its specified temperature range.

14. **Software/Settings**: Check any software or settings related to the thermocouple for errors or misconfigurations.