Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What are carbon steel long products?

Carbon steel long products are a category of steel products that are characterized by their elongated shapes and are primarily made from carbon steel, which is an alloy of iron and carbon. These products are typically used in construction, infrastructure, and manufacturing due to their strength, durability, and versatility.

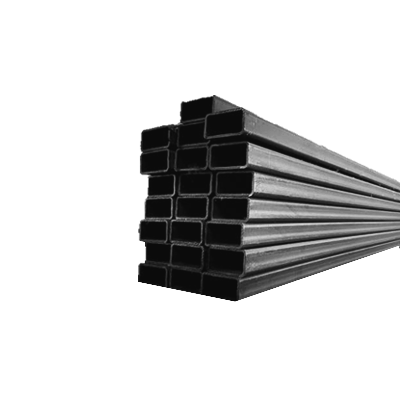

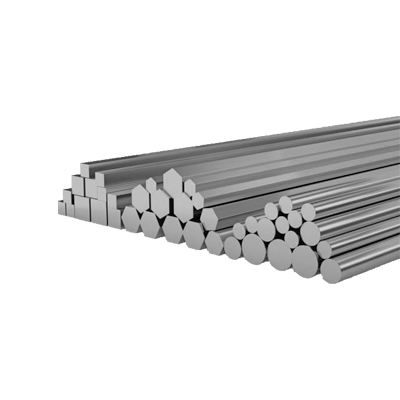

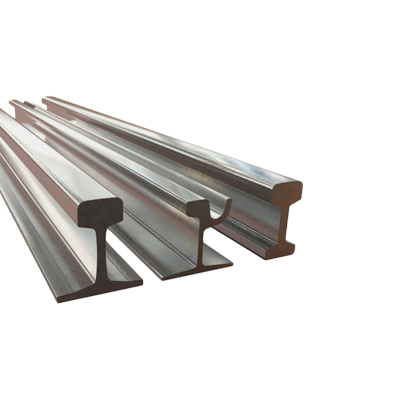

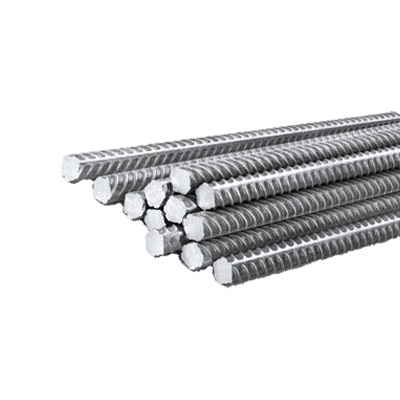

The main types of carbon steel long products include:

1. **Bars**: These are solid, long pieces of steel that can be round, square, or hexagonal in shape. They are used in the manufacturing of machinery, automotive components, and construction reinforcements.

2. **Rods**: Similar to bars, rods are long, cylindrical pieces of steel. They are often used in construction for reinforcing concrete structures, as well as in the production of bolts and fasteners.

3. **Beams**: These are structural elements that primarily resist loads applied laterally to the beam's axis. They are commonly used in building construction and civil engineering projects.

4. **Angles**: These are L-shaped steel pieces used in various structural applications, including frameworks and supports.

5. **Channels**: These are U-shaped steel products used in construction and manufacturing for structural support and framing.

6. **Rails**: Specifically designed for railway tracks, these long steel products are crucial for the transportation industry.

Carbon steel long products are produced through processes such as hot rolling, which involves heating steel billets and shaping them into the desired form. The carbon content in these products can vary, affecting their hardness, ductility, and tensile strength. Low-carbon steel is more ductile and easier to work with, while high-carbon steel is harder and stronger but less ductile. These properties make carbon steel long products essential in various industries, providing the necessary support and strength for numerous applications.

What are the main uses of carbon steel long products in construction?

Carbon steel long products are extensively used in construction due to their strength, durability, and versatility. The main uses include:

1. **Structural Frameworks**: Carbon steel beams, columns, and channels form the backbone of buildings and bridges, providing essential support and stability.

2. **Reinforcement**: Rebar (reinforcing bars) made from carbon steel is embedded in concrete to enhance its tensile strength, crucial for constructing foundations, walls, and slabs.

3. **Infrastructure**: Used in the construction of roads, railways, and tunnels, carbon steel long products offer the necessary strength and resilience to withstand heavy loads and environmental stress.

4. **Industrial Buildings**: In factories and warehouses, carbon steel is used for constructing frameworks, roofing, and cladding, ensuring durability and resistance to wear and tear.

5. **High-rise Buildings**: The high strength-to-weight ratio of carbon steel makes it ideal for skyscrapers, allowing for taller structures with reduced material usage.

6. **Bridges**: Carbon steel is used in the construction of bridges due to its ability to support large spans and resist dynamic loads from traffic and environmental factors.

7. **Pipelines**: Carbon steel pipes are used for transporting water, gas, and other fluids, essential for urban infrastructure and industrial applications.

8. **Fencing and Railings**: Durable and resistant to impact, carbon steel is used for security fencing, railings, and barriers in both residential and commercial settings.

9. **Utility Poles and Transmission Towers**: Carbon steel provides the necessary strength and durability for supporting electrical and telecommunication lines.

10. **Miscellaneous Applications**: Includes the construction of staircases, ladders, and other architectural elements where strength and longevity are required.

These applications highlight the critical role of carbon steel long products in ensuring the safety, functionality, and longevity of construction projects.

How does carbon content affect the properties of carbon steel long products?

Carbon content significantly influences the properties of carbon steel long products. As carbon content increases, the hardness and strength of the steel also increase due to the formation of iron carbide (Fe3C), which impedes dislocation movement within the steel's crystal lattice. This results in enhanced wear resistance, making high-carbon steels suitable for applications requiring durability, such as cutting tools and springs.

However, increased carbon content also reduces ductility and toughness. High-carbon steels become more brittle and are prone to cracking under stress, limiting their use in applications where flexibility and impact resistance are crucial. This brittleness is due to the reduced ability of the steel to deform plastically before fracturing.

Weldability is another property affected by carbon content. Higher carbon steels are more challenging to weld because they are susceptible to cracking in the heat-affected zone. Preheating and post-weld heat treatments are often necessary to mitigate these issues.

Machinability is also impacted, with higher carbon steels being more difficult to machine due to their increased hardness. This can lead to higher tool wear and the need for specialized cutting tools and techniques.

In summary, carbon content in carbon steel long products is a critical factor that determines their mechanical properties and suitability for various applications. Low-carbon steels are more ductile and weldable, making them ideal for construction and structural applications, while high-carbon steels offer superior hardness and strength for wear-resistant applications but at the cost of reduced ductility and weldability.

What is the typical carbon content range in carbon steel long products?

The typical carbon content range in carbon steel long products is between 0.05% and 1.70% by weight. This range allows for a variety of mechanical properties and applications.

- **Low Carbon Steel (Mild Steel):** Contains approximately 0.05% to 0.30% carbon. It is highly ductile, malleable, and easy to weld, making it suitable for products like structural beams, rebar, and wire rods.

- **Medium Carbon Steel:** Contains about 0.30% to 0.60% carbon. It offers a balance between strength and ductility, making it ideal for applications such as railway tracks, gears, and axles.

- **High Carbon Steel:** Contains approximately 0.60% to 1.00% carbon. It is known for its high strength and hardness but lower ductility, suitable for products like springs and high-strength wires.

- **Ultra-High Carbon Steel:** Contains 1.00% to 1.70% carbon. It is extremely hard and brittle, used in specialized applications like cutting tools and knives.

The carbon content significantly influences the steel's hardness, tensile strength, and ductility, with higher carbon content generally increasing hardness and strength while reducing ductility.

How are carbon steel long products manufactured?

Carbon steel long products are manufactured through a series of processes that transform raw materials into finished goods. The process begins with the extraction of iron ore, which is then smelted in a blast furnace to produce molten iron. This molten iron is combined with carbon and other alloying elements to form carbon steel.

The next step is casting, where the molten steel is poured into molds to form billets, blooms, or slabs. These semi-finished products are then subjected to hot rolling, a process where they are heated and passed through a series of rolling mills to reduce their thickness and shape them into long products such as bars, rods, and structural sections.

After hot rolling, the products may undergo further processing such as cold rolling, which involves rolling the steel at room temperature to achieve tighter tolerances and improved surface finish. Cold drawing may also be used to produce wire and other precision products.

Heat treatment processes like annealing, quenching, and tempering may be applied to enhance the mechanical properties of the steel, such as strength and ductility. Surface treatments, including galvanizing or coating, can be applied to improve corrosion resistance.

Quality control measures are implemented throughout the manufacturing process to ensure the products meet specified standards and customer requirements. This includes chemical analysis, mechanical testing, and dimensional inspections.

Finally, the finished long products are cut to length, bundled, and prepared for shipment to various industries, including construction, automotive, and manufacturing, where they are used in applications ranging from reinforcing bars in concrete to components in machinery and equipment.

What are the benefits of using carbon steel long products in manufacturing?

Carbon steel long products offer several benefits in manufacturing:

1. **Strength and Durability**: Carbon steel is known for its high tensile strength, making it ideal for applications requiring durability and resistance to wear and tear. This makes it suitable for construction, automotive, and heavy machinery industries.

2. **Cost-Effectiveness**: Compared to other metals like stainless steel or aluminum, carbon steel is more affordable. Its cost-effectiveness makes it a popular choice for large-scale manufacturing projects where budget constraints are a concern.

3. **Versatility**: Carbon steel long products, such as bars, rods, and beams, can be easily fabricated into various shapes and sizes. This versatility allows manufacturers to use them in a wide range of applications, from structural components to intricate machinery parts.

4. **Weldability and Machinability**: Carbon steel is relatively easy to weld and machine, which simplifies the manufacturing process. This property reduces production time and costs, enhancing overall efficiency.

5. **Recyclability**: Carbon steel is 100% recyclable, making it an environmentally friendly option. Its recyclability helps manufacturers reduce waste and lower their carbon footprint, aligning with sustainable practices.

6. **Corrosion Resistance**: While not as corrosion-resistant as stainless steel, carbon steel can be treated with coatings or galvanization to enhance its resistance to rust and corrosion, extending the lifespan of the products.

7. **Thermal Conductivity**: Carbon steel has good thermal conductivity, which is beneficial in applications requiring heat transfer, such as in heat exchangers and radiators.

8. **Availability**: Carbon steel is widely available, ensuring a steady supply for manufacturers. This availability helps in maintaining consistent production schedules without delays.

These benefits make carbon steel long products a preferred choice in various manufacturing sectors, balancing performance, cost, and sustainability.

How does hot rolling improve the properties of carbon steel long products?

Hot rolling improves the properties of carbon steel long products through several mechanisms. Firstly, it refines the grain structure. During hot rolling, the steel is heated above its recrystallization temperature, which allows new grains to form without the pre-existing grain boundaries. This results in a finer and more uniform grain structure, enhancing the mechanical properties such as toughness and ductility.

Secondly, hot rolling reduces the porosity and eliminates internal voids. The high temperature and pressure during the process help to close up any internal defects, leading to a denser and more homogeneous material. This improves the overall strength and integrity of the steel.

Thirdly, hot rolling enhances the steel's mechanical properties by work hardening. As the steel is deformed, dislocations within the crystal structure increase, which strengthens the material. This process also aligns the microstructure in the direction of rolling, improving directional properties like tensile strength and impact resistance.

Additionally, hot rolling improves surface finish and dimensional accuracy. The process smooths out surface irregularities and allows for precise control over the final dimensions of the product, which is crucial for applications requiring tight tolerances.

Finally, hot rolling can improve the steel's weldability and machinability. The refined grain structure and reduced impurities make the steel easier to weld and machine, which is beneficial for manufacturing and construction applications.

Overall, hot rolling enhances the mechanical properties, surface quality, and workability of carbon steel long products, making them suitable for a wide range of industrial applications.

What factors drive the demand for carbon steel long products?

The demand for carbon steel long products is driven by several key factors:

1. **Construction Industry**: The construction sector is a major consumer of carbon steel long products, such as beams, bars, and rods, used in infrastructure projects, residential buildings, and commercial structures. Urbanization and government investments in infrastructure development significantly boost demand.

2. **Automotive Industry**: Carbon steel long products are used in manufacturing automotive components like axles, chassis, and suspension systems. The growth of the automotive industry, driven by increasing vehicle production and technological advancements, influences demand.

3. **Industrialization and Economic Growth**: Rapid industrialization in emerging economies leads to increased demand for machinery and equipment, which in turn drives the need for carbon steel long products. Economic growth stimulates construction and manufacturing activities, further boosting demand.

4. **Energy Sector**: The energy sector, including oil and gas, wind, and solar power, requires carbon steel long products for pipelines, transmission towers, and other infrastructure. Expansion in energy projects, especially renewable energy, contributes to demand.

5. **Technological Advancements**: Innovations in steel production and processing technologies enhance the quality and performance of carbon steel long products, making them more attractive to various industries.

6. **Global Trade Policies**: Tariffs, trade agreements, and import-export regulations impact the availability and pricing of carbon steel long products, influencing demand in different regions.

7. **Raw Material Prices**: Fluctuations in the prices of raw materials like iron ore and coal affect production costs and, consequently, the pricing and demand for carbon steel long products.

8. **Sustainability Trends**: Increasing focus on sustainable construction practices and the recyclability of steel can drive demand, as industries seek environmentally friendly materials.

9. **Supply Chain Dynamics**: The efficiency and reliability of supply chains, including transportation and distribution networks, play a crucial role in meeting demand for carbon steel long products.

Who are the key producers of carbon steel long products?

Key producers of carbon steel long products include:

1. **ArcelorMittal**: As the world's leading steel and mining company, ArcelorMittal produces a wide range of steel products, including long products such as bars, rods, and structural sections. They have operations in over 60 countries and a significant presence in Europe, the Americas, Asia, and Africa.

2. **Nippon Steel Corporation**: Based in Japan, Nippon Steel is one of the largest steel producers globally. They manufacture a variety of long products, including wire rods and bars, catering to construction and industrial sectors.

3. **Tata Steel**: Headquartered in India, Tata Steel is a major player in the global steel industry. They produce long products like rebars, wire rods, and structural steel, serving markets in India, Europe, and Southeast Asia.

4. **POSCO**: A South Korean steel-making company, POSCO is known for its advanced technology and high-quality steel products. They produce long products such as wire rods and bars, primarily for the construction and automotive industries.

5. **Gerdau**: A leading producer in the Americas, Gerdau is based in Brazil and specializes in long steel products. They supply rebars, wire rods, and structural shapes to the construction and industrial sectors.

6. **Nucor Corporation**: As the largest steel producer in the United States, Nucor manufactures a wide range of long products, including beams, bars, and rebar, primarily for the North American market.

7. **JSW Steel**: An Indian multinational, JSW Steel is a significant producer of long products, including TMT bars and wire rods, with a strong presence in the Indian market and growing international operations.

8. **EVRAZ**: A multinational vertically integrated steel making and mining company, EVRAZ is based in the UK and Russia, producing long products like rails, beams, and rebars for construction and infrastructure projects.

How are producers addressing sustainability in the production of carbon steel long products?

Producers are addressing sustainability in the production of carbon steel long products through several key strategies. Firstly, they are optimizing energy efficiency by upgrading to more efficient technologies and processes, such as electric arc furnaces (EAFs), which use recycled scrap steel and consume less energy compared to traditional blast furnaces. This shift not only reduces energy consumption but also lowers greenhouse gas emissions.

Secondly, the industry is increasing the use of recycled materials. By maximizing the use of scrap steel, producers minimize the need for virgin raw materials, thereby conserving natural resources and reducing the environmental impact associated with mining and raw material extraction.

Thirdly, producers are investing in research and development to innovate new production techniques that reduce carbon emissions. This includes the development of low-carbon steelmaking processes, such as hydrogen-based direct reduction, which replaces carbon-intensive methods with cleaner alternatives.

Additionally, companies are implementing circular economy principles by designing products for longer life cycles and recyclability. This approach ensures that steel products can be reused or recycled at the end of their life, further reducing waste and resource consumption.

Moreover, producers are adopting environmental management systems and certifications, such as ISO 14001, to systematically manage their environmental responsibilities. These systems help in monitoring and improving environmental performance, ensuring compliance with regulations, and promoting transparency.

Finally, collaboration with stakeholders, including governments, industry groups, and NGOs, is crucial. By working together, producers can develop industry-wide standards and practices that promote sustainability and drive collective action towards reducing the carbon footprint of steel production.

Through these combined efforts, producers are making significant strides towards more sustainable production of carbon steel long products, aligning with global sustainability goals and responding to increasing demand for environmentally responsible manufacturing.