Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What is rebar used for?

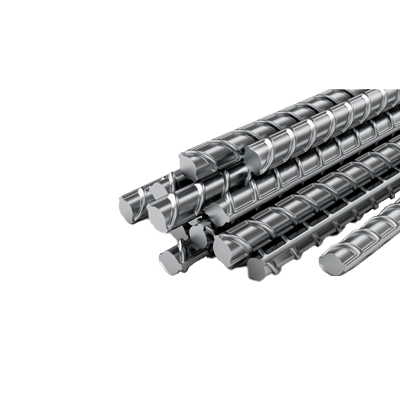

Rebar, short for reinforcing bar, is used to enhance the tensile strength of concrete, which is inherently strong in compression but weak in tension. By embedding rebar within concrete structures, engineers can significantly improve their load-bearing capacity and durability. Rebar is typically made from steel, which has excellent tensile properties, making it ideal for this purpose.

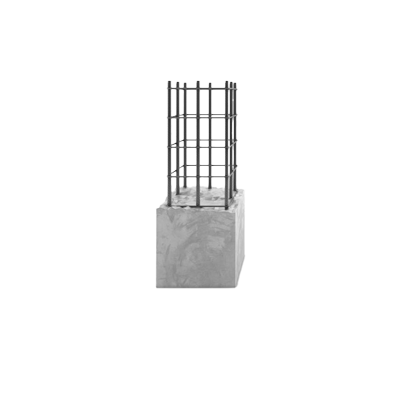

In construction, rebar is used in a variety of applications, including the reinforcement of concrete slabs, beams, columns, and foundations. It is essential in the construction of buildings, bridges, roads, and other infrastructure projects. The use of rebar helps prevent cracking and structural failure by distributing tensile forces across a wider area, thus increasing the overall stability and longevity of the structure.

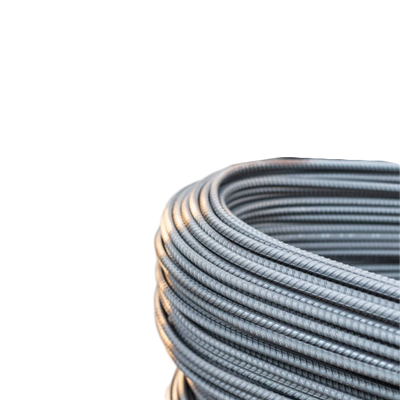

Rebar is available in different sizes and grades, allowing for customization based on specific project requirements. It is often arranged in a grid pattern and tied together with wire to form a reinforcing cage before concrete is poured. This ensures that the rebar is properly positioned within the concrete to provide maximum reinforcement.

Additionally, rebar can be coated with materials such as epoxy to protect it from corrosion, especially in environments exposed to moisture or chemicals. This extends the lifespan of the concrete structure by preventing rust, which can lead to structural degradation.

Overall, rebar is a critical component in modern construction, providing the necessary tensile strength to concrete structures, ensuring their safety, stability, and longevity.

How is rebar made?

Rebar, or reinforcing bar, is made through a series of steps involving the processing of steel. The process begins with the selection of raw materials, primarily iron ore, coal, and limestone. These materials are melted together in a blast furnace to produce molten iron. This molten iron is then converted into steel in a basic oxygen furnace or an electric arc furnace, where impurities are removed, and alloying elements are added to achieve the desired chemical composition.

Once the steel is produced, it is cast into billets, which are long rectangular blocks. These billets are then heated in a reheat furnace to a temperature suitable for hot rolling. The hot billets are passed through a series of rolling stands, which progressively shape them into the desired diameter and length of rebar. During this process, the steel is elongated and reduced in cross-section, forming the characteristic ribbed pattern on the surface of the rebar, which enhances its bonding with concrete.

After rolling, the rebar is cooled, typically using a controlled cooling process known as quenching and tempering. This process involves rapid cooling followed by reheating, which improves the mechanical properties of the rebar, such as its strength and ductility.

The final step involves cutting the rebar to the required lengths and bundling them for shipment. Quality control measures, including testing for tensile strength, yield strength, and elongation, ensure that the rebar meets industry standards and specifications.

Rebar can also be produced from recycled steel, which involves melting scrap steel in an electric arc furnace and following similar steps of casting, rolling, and cooling. This method is more environmentally friendly and cost-effective.

What are the different types of rebar?

Rebar, or reinforcing bar, is a crucial component in construction, providing tensile strength to concrete structures. There are several types of rebar, each suited for specific applications:

1. **Carbon Steel Rebar**: The most common type, known for its strength and cost-effectiveness. It is used in a wide range of construction projects but is susceptible to corrosion.

2. **Epoxy-Coated Rebar**: This is carbon steel rebar coated with epoxy to resist corrosion. It is ideal for environments exposed to moisture and chemicals, such as marine structures and bridges.

3. **Stainless Steel Rebar**: Offers superior corrosion resistance and durability, making it suitable for highly corrosive environments. It is more expensive but provides long-term benefits in terms of maintenance and longevity.

4. **Galvanized Rebar**: Coated with a layer of zinc to protect against corrosion. It is less effective than epoxy-coated rebar but more cost-effective and easier to handle.

5. **Glass-Fiber-Reinforced-Polymer (GFRP) Rebar**: Made from fiberglass, it is non-corrosive and lightweight, making it ideal for structures exposed to harsh chemicals or electromagnetic fields.

6. **Basalt Rebar**: Composed of basalt rock fibers, it is non-corrosive, lightweight, and has a high strength-to-weight ratio. It is used in applications where weight reduction is crucial.

7. **Welded Wire Fabric (WWF)**: A grid of steel wires welded together, used for reinforcing slabs and walls. It provides uniform stress distribution and is easy to install.

8. **Expanded Metal or Wire Mesh Rebar**: Used for reinforcing thin concrete sections, it is made by expanding metal sheets into a mesh pattern.

Each type of rebar has unique properties that make it suitable for specific construction needs, balancing factors like cost, strength, and environmental resistance.

How do you calculate the amount of rebar needed for a project?

To calculate the amount of rebar needed for a project, follow these steps:

1. **Determine the Structural Requirements**: Review the structural drawings and specifications to understand the rebar requirements, including size, spacing, and placement.

2. **Calculate the Volume of Concrete**: Measure the dimensions of the concrete elements (slabs, beams, columns, etc.) to calculate the volume of concrete. Use the formula: Volume = Length × Width × Height.

3. **Identify Rebar Density**: Refer to the design specifications or building codes to determine the rebar density, typically expressed as weight per cubic meter or foot of concrete.

4. **Calculate Total Rebar Weight**: Multiply the concrete volume by the rebar density to find the total weight of rebar needed.

5. **Determine Rebar Length**: Based on the structural design, calculate the total length of each rebar size required. Consider the spacing and overlap (lap splice) requirements.

6. **Account for Waste and Overlaps**: Add a percentage (commonly 5-10%) to account for cutting waste, overlaps, and bends.

7. **Convert Weight to Length**: If needed, convert the total weight of rebar to length using the weight per unit length of the rebar, which depends on the rebar size (e.g., kg/m or lb/ft).

8. **Create a Rebar Schedule**: List all rebar types, sizes, lengths, and quantities in a rebar schedule for ordering and installation.

9. **Verify with Structural Engineer**: Ensure calculations align with structural requirements and consult with a structural engineer for validation.

10. **Order Rebar**: Based on the rebar schedule, order the required quantities from a supplier.

By following these steps, you can accurately calculate the amount of rebar needed for a construction project.

What are the standard sizes of rebar?

Rebar, or reinforcing bar, is used in construction to provide tensile strength to concrete structures. The standard sizes of rebar are typically designated by numbers that correspond to the nominal diameter of the bar in eighths of an inch in the United States. Here are the standard sizes:

1. **#3 Rebar**: 3/8 inch in diameter.

2. **#4 Rebar**: 1/2 inch in diameter.

3. **#5 Rebar**: 5/8 inch in diameter.

4. **#6 Rebar**: 3/4 inch in diameter.

5. **#7 Rebar**: 7/8 inch in diameter.

6. **#8 Rebar**: 1 inch in diameter.

7. **#9 Rebar**: 1 1/8 inches in diameter.

8. **#10 Rebar**: 1 1/4 inches in diameter.

9. **#11 Rebar**: 1 3/8 inches in diameter.

10. **#14 Rebar**: 1 3/4 inches in diameter.

11. **#18 Rebar**: 2 1/4 inches in diameter.

These sizes are standardized by the American Society for Testing and Materials (ASTM) and are commonly used in the United States. The metric system, used in many other countries, designates rebar sizes differently, typically by the nominal diameter in millimeters. For example, a #10 rebar in the U.S. is approximately equivalent to a 32 mm rebar in the metric system.

Rebar is also categorized by its grade, which indicates the yield strength of the steel. Common grades include Grade 40, Grade 60, and Grade 75, with the number representing the yield strength in ksi (kilo-pound per square inch).

These standard sizes and grades ensure that rebar can be used effectively in various construction applications, providing the necessary support and stability to concrete structures.

How do you cut and bend rebar?

To cut and bend rebar, follow these steps:

1. **Preparation**:

- Wear safety gear: gloves, goggles, and steel-toed boots.

- Measure and mark the rebar using chalk or a permanent marker where cuts and bends are needed.

2. **Cutting Rebar**:

- **Manual Method**: Use a hacksaw or bolt cutters for small diameter rebar. Position the rebar on a stable surface, align the tool with the marked line, and apply steady pressure to cut through.

- **Power Tools**: For larger projects, use a rebar cutter or an angle grinder with a metal cutting disc. Secure the rebar in a vise or clamp, align the tool with the mark, and cut through with controlled movements.

3. **Bending Rebar**:

- **Manual Bending**: Use a rebar bender or a bending tool. Insert the rebar into the bender, align it with the desired angle, and pull the handle to bend. For small adjustments, a pipe or a cheater bar can be used to gain leverage.

- **Hydraulic Bender**: For thicker rebar, use a hydraulic rebar bender. Place the rebar in the machine, set the desired angle, and activate the hydraulic system to bend the rebar precisely.

4. **Quality Check**:

- Ensure cuts are clean and bends are at the correct angle.

- Use a protractor or angle finder to verify the accuracy of bends.

5. **Safety and Maintenance**:

- Regularly inspect tools for wear and tear.

- Store tools properly to maintain their condition.

By following these steps, rebar can be cut and bent efficiently and safely for construction projects.

What is the difference between rebar grades?

Rebar, or reinforcing bar, is used to reinforce concrete structures, and its grades indicate the strength and composition of the steel. The primary differences between rebar grades are based on their yield strength, tensile strength, and chemical composition.

1. **Yield Strength**: This is the stress at which a material begins to deform plastically. Rebar grades are often denoted by their yield strength in thousands of pounds per square inch (ksi). For example, Grade 40 rebar has a yield strength of 40 ksi, while Grade 60 has 60 ksi. Higher grades like Grade 75, 80, or 100 have even greater yield strengths, making them suitable for more demanding applications.

2. **Tensile Strength**: This is the maximum stress that a material can withstand while being stretched or pulled before breaking. Higher-grade rebars typically have higher tensile strengths, which means they can handle more stress before failing.

3. **Chemical Composition**: Different grades may have varying chemical compositions, affecting their ductility, weldability, and corrosion resistance. For instance, some grades include additional elements like chromium or vanadium to enhance specific properties.

4. **Application**: Lower-grade rebars (e.g., Grade 40) are often used in residential construction, where the loads are lighter. Higher grades (e.g., Grade 60, 75, or 100) are used in commercial and industrial projects, such as bridges and high-rise buildings, where greater strength is required.

5. **Cost**: Higher-grade rebars are typically more expensive due to their enhanced properties and the additional processing required to achieve those properties.

Understanding these differences is crucial for selecting the appropriate rebar grade for specific construction needs, ensuring structural integrity and cost-effectiveness.