- Home

- Steel

.....Read More

Alloy Steel - Low-Alloy Steel (e.g., 4140, 4340, 6150)

Carbon Steel - Flat Products

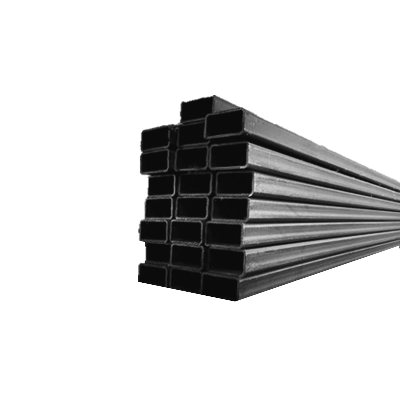

Carbon Steel - Long Products

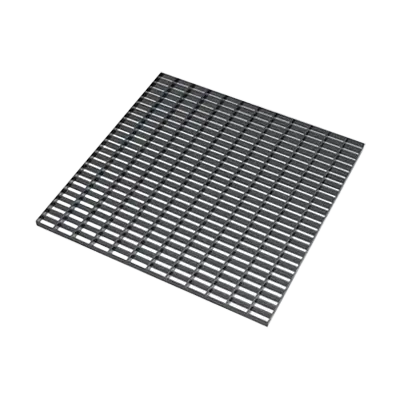

Fabricated Products - Grating

Special Steel - Case-Hardening Steel (Low-Carbon, e.g., 1018, 8620)

Special Steel - Machining Steel

Special Steel - Spring Steel

Special Steel - Tempered Steel

Special Steel - Tool Steel

Special Steel - Transmission Bar

Stainless Steel - Flat Products

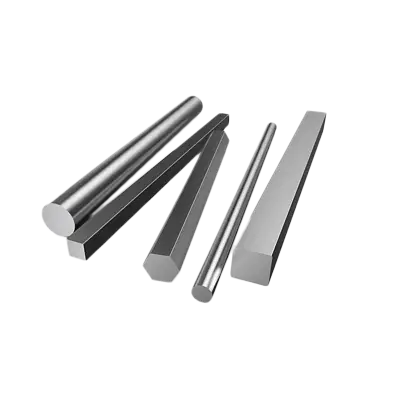

Stainless Steel - Long Products

Wire and Fence Products - Fence Products

Wire and Fence Products - Wires

Frequently Asked Questions

What are the different types of steel?

How is steel made?

What are the properties of steel?

What is the difference between steel and iron?

What are the uses of steel in construction?

How strong is steel compared to other materials?

What is stainless steel and its applications?

How is steel recycled?

What are the environmental impacts of steel production?

How much does steel cost per ton?