Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

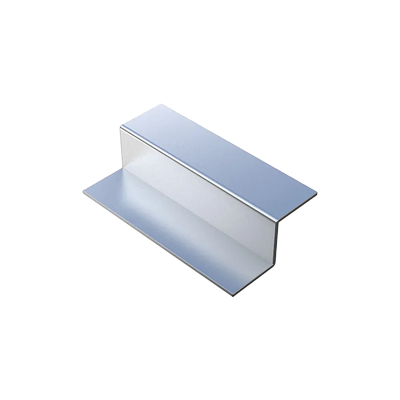

- Steel

- Carbon Steel Long Products

- Merchant Bar

.....Read More

Frequently Asked Questions

What are merchant bars used for?

Merchant bars are versatile steel products used in a variety of construction and industrial applications. They are typically produced in various shapes such as rounds, squares, flats, angles, and channels, each serving specific purposes.

1. **Construction**: Merchant bars are widely used in the construction industry for structural support. They are employed in the fabrication of frames, beams, and columns, providing essential strength and stability to buildings and infrastructure projects.

2. **Manufacturing**: In manufacturing, merchant bars are used to produce machinery parts, tools, and equipment. Their adaptability allows them to be cut, welded, and formed into various components necessary for industrial machinery and vehicles.

3. **Fabrication**: These bars are essential in metal fabrication processes. They are used to create custom metal structures, gates, railings, and other architectural elements, offering both functional and aesthetic benefits.

4. **Reinforcement**: Merchant bars are often used as reinforcement in concrete structures. They enhance the tensile strength of concrete, making it more durable and resistant to cracking under stress.

5. **Agricultural Equipment**: In the agricultural sector, merchant bars are used to manufacture equipment such as plows, harrows, and other farming implements, contributing to the efficiency and durability of agricultural operations.

6. **Transportation**: The transportation industry utilizes merchant bars in the production of trailers, truck bodies, and railway components, where strength and reliability are crucial.

7. **General Repairs and Maintenance**: Due to their availability and ease of use, merchant bars are frequently used in repair and maintenance tasks across various industries, providing quick and effective solutions for structural and mechanical issues.

Overall, merchant bars are integral to numerous sectors due to their strength, versatility, and adaptability, making them a fundamental component in both large-scale projects and everyday applications.

What sizes do merchant bars come in?

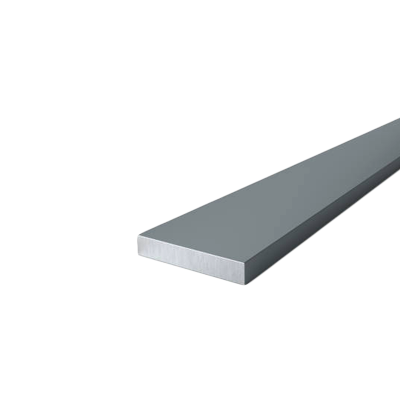

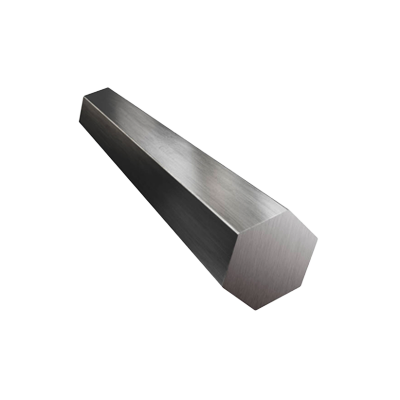

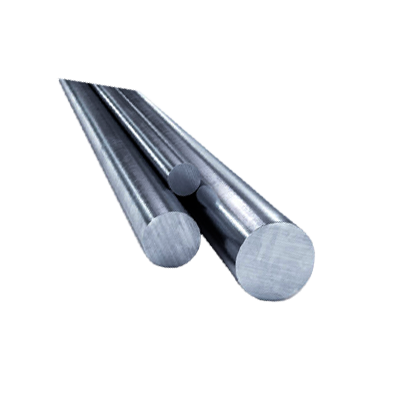

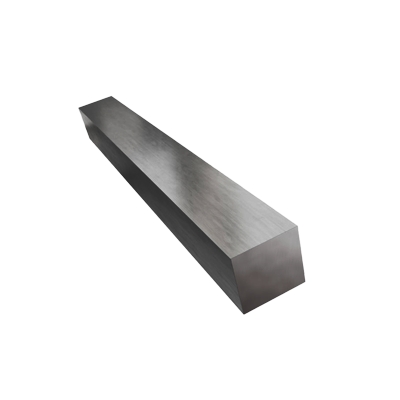

Merchant bars come in a variety of sizes, typically defined by their cross-sectional dimensions and lengths. These bars are commonly used in construction, manufacturing, and fabrication industries. The sizes can vary based on the type of merchant bar, which includes flat bars, round bars, square bars, and angle bars.

1. **Flat Bars**: These are available in widths ranging from 10 mm to 300 mm and thicknesses from 3 mm to 50 mm. Lengths typically range from 6 meters to 12 meters.

2. **Round Bars**: These bars come in diameters ranging from 5 mm to 100 mm. Standard lengths are usually 6 meters, but they can also be found in lengths up to 12 meters.

3. **Square Bars**: Sizes for square bars range from 6 mm x 6 mm to 100 mm x 100 mm. Like other bars, they are commonly available in lengths of 6 meters.

4. **Angle Bars**: These are available in equal and unequal angles. Sizes for equal angles range from 20 mm x 20 mm to 200 mm x 200 mm, with thicknesses from 3 mm to 20 mm. Unequal angles can range from 30 mm x 20 mm to 200 mm x 150 mm, with similar thicknesses. Standard lengths are typically 6 meters or 12 meters.

These sizes can vary slightly based on regional standards and manufacturer specifications. Custom sizes may also be available upon request for specific projects.

What materials are merchant bars made from?

Merchant bars are typically made from carbon steel, which is an alloy of iron and carbon. The carbon content in these steels usually ranges from 0.05% to 0.25%, which provides a balance of strength and ductility. In addition to carbon, other elements such as manganese, silicon, and sometimes small amounts of copper, nickel, chromium, or molybdenum may be added to enhance specific properties like strength, corrosion resistance, or machinability.

The steel used for merchant bars is often hot-rolled, a process that involves rolling the steel at a high temperature, which makes it easier to shape and form. This process also helps in refining the grain structure and improving the mechanical properties of the steel.

Merchant bars can come in various shapes and sizes, including rounds, squares, flats, angles, and channels, and are used in a wide range of applications such as construction, manufacturing, and fabrication. The choice of material and specific alloy composition can vary depending on the intended use and required properties, such as tensile strength, yield strength, and elongation.

In some cases, low-alloy steels may be used for merchant bars to provide additional strength and toughness. These steels contain small amounts of alloying elements, typically less than 5% by weight, which can significantly enhance the mechanical properties without compromising weldability or formability.

Overall, the materials used for merchant bars are selected to provide a combination of strength, durability, and cost-effectiveness, making them suitable for a variety of structural and industrial applications.

How are merchant bars manufactured?

Merchant bars are manufactured through a series of processes in a steel mill. The process begins with the melting of raw materials, primarily iron ore, scrap metal, and other alloying elements, in a furnace to produce molten steel. This molten steel is then poured into a casting machine to form billets, which are long, rectangular pieces of steel.

Once the billets are formed, they are reheated in a reheat furnace to a temperature suitable for rolling. The heated billets are then passed through a series of rolling stands in a rolling mill. These stands progressively reduce the cross-sectional area of the billets and shape them into the desired profile of merchant bars, such as rounds, squares, flats, or angles.

During the rolling process, the steel is subjected to mechanical working, which improves its mechanical properties and surface finish. The rolling process may involve several passes through different sets of rolls to achieve the precise dimensions and surface quality required.

After rolling, the merchant bars are cooled, typically on a cooling bed, to room temperature. This controlled cooling process helps in achieving the desired mechanical properties and prevents defects such as warping or cracking.

Once cooled, the bars are cut to the required lengths using shearing machines. They are then inspected for quality, ensuring they meet the specified standards and dimensions. Any defective bars are removed from the production line.

Finally, the merchant bars are bundled, tagged, and prepared for shipment to customers. They are used in various applications, including construction, manufacturing, and fabrication, due to their versatility and strength.

What are the different grades of merchant bars?

Merchant bars are categorized based on their shape, size, and the specific standards they meet. Here are the different grades:

1. **ASTM A36**: This is the most common grade for merchant bars. It is a low carbon steel with good strength and formability, suitable for welding and machining.

2. **ASTM A572**: This grade offers higher strength compared to A36 and is available in several yield strength levels, such as 42, 50, 55, 60, and 65 ksi. It is used in applications requiring increased strength.

3. **ASTM A529**: Similar to A572, this grade is used for high-strength applications and is available in yield strengths of 50 and 55 ksi.

4. **ASTM A588**: Known for its weathering properties, this grade is used in environments where resistance to atmospheric corrosion is important.

5. **ASTM A992**: Primarily used in structural applications, this grade offers high strength and is commonly used in the construction of buildings and bridges.

6. **ASTM A500**: This grade is used for cold-formed welded and seamless carbon steel structural tubing in round, square, and rectangular shapes.

7. **ASTM A615**: This grade is used for deformed and plain carbon-steel bars for concrete reinforcement.

8. **ASTM A706**: This grade is used for low-alloy steel deformed and plain bars for concrete reinforcement, offering improved ductility and weldability.

9. **ASTM A615/A615M**: This is a specification for deformed and plain carbon-steel bars for concrete reinforcement, available in various grades based on yield strength.

10. **ASTM A996**: This grade is used for rail-steel and axle-steel deformed bars for concrete reinforcement.

These grades are selected based on the specific requirements of the project, including strength, ductility, weldability, and resistance to environmental factors.

How do you cut and weld merchant bars?

To cut and weld merchant bars, follow these steps:

1. **Cutting:**

- **Tools Required:** Use a metal cutting saw, angle grinder with a cutting disc, or a band saw.

- **Preparation:** Measure and mark the desired length on the merchant bar using a tape measure and a marker or scribe.

- **Safety Gear:** Wear safety goggles, gloves, and protective clothing.

- **Cutting Process:** Secure the bar in a vise or clamp to prevent movement. Align the cutting tool with the marked line and proceed to cut slowly and steadily to ensure a clean cut. For thicker bars, a band saw may be more efficient.

2. **Welding:**

- **Tools Required:** Use a MIG welder, TIG welder, or stick welder depending on the material and thickness.

- **Preparation:** Clean the edges of the bars to be welded using a wire brush or grinder to remove rust, paint, or any contaminants.

- **Alignment:** Position the bars in the desired configuration, using clamps or a jig to hold them in place.

- **Tack Welding:** Apply tack welds at intervals to hold the bars together temporarily. This helps maintain alignment during the welding process.

- **Welding Process:** Weld along the joint using the appropriate welding technique. For MIG welding, adjust the voltage and wire feed speed according to the material thickness. For TIG welding, use a filler rod if necessary. For stick welding, select the correct electrode.

- **Cooling:** Allow the welded joint to cool naturally to prevent warping.

- **Finishing:** Grind the welds if a smooth finish is required.

Always follow safety protocols and manufacturer guidelines for equipment use.

Where can I buy merchant bars?

You can purchase merchant bars from a variety of sources, including:

1. **Steel Manufacturers and Mills**: Many steel manufacturers produce merchant bars and sell them directly to consumers or through distributors. Companies like ArcelorMittal, Nucor, and Gerdau are well-known producers.

2. **Metal Distributors and Suppliers**: These companies specialize in distributing various metal products, including merchant bars. Examples include Ryerson, Kloeckner Metals, and Reliance Steel & Aluminum Co.

3. **Online Metal Marketplaces**: Websites like OnlineMetals.com, Metal Supermarkets, and Industrial Metal Supply offer a wide range of metal products, including merchant bars, which can be ordered online and shipped directly to you.

4. **Local Metal Fabrication Shops**: Many local metal shops keep an inventory of merchant bars for their fabrication projects and may sell directly to the public.

5. **Construction Supply Stores**: Some construction supply companies stock merchant bars as part of their inventory for building materials.

6. **Industrial Auctions and Surplus Sales**: Occasionally, industrial auctions or surplus sales may offer merchant bars at discounted prices.

7. **Trade Shows and Expos**: Attending industry trade shows can provide opportunities to connect with manufacturers and distributors who sell merchant bars.

8. **B2B Marketplaces**: Platforms like Alibaba or Global Sources allow you to connect with international suppliers who offer merchant bars.

When purchasing merchant bars, consider factors such as the required specifications, quantity, delivery options, and pricing. It's also advisable to verify the credibility of the supplier and ensure they meet industry standards for quality.