Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Steel

- Carbon Steel Long Products

- Structural Steel

.....Read More

Frequently Asked Questions

What are the different types of structural steel shapes?

Structural steel shapes are categorized based on their cross-sectional profiles and are used in construction and engineering projects. The primary types include:

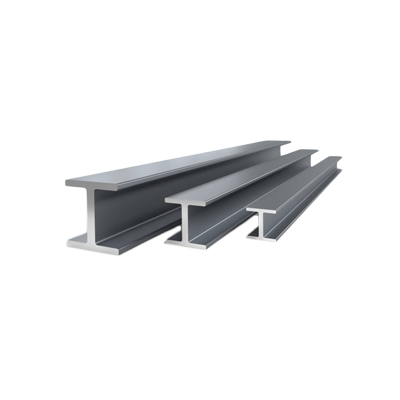

1. **I-Beam (or H-Beam):** Characterized by its I-shaped cross-section, it is used for beams and columns. The flanges are parallel, and it is known for its strength and efficiency in load-bearing.

2. **W-Beam (Wide Flange):** Similar to I-beams but with wider flanges, providing better load distribution. They are versatile and used in various structural applications.

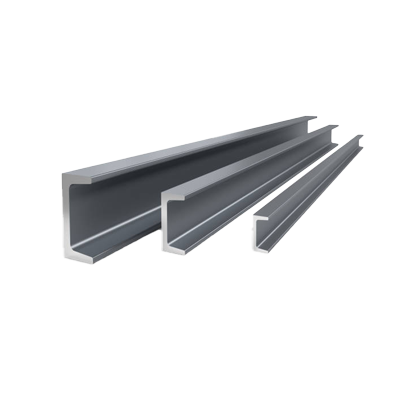

3. **Channel (C-Shaped):** Features a C-shaped cross-section with a vertical web and two horizontal flanges. It is used for structural support in building frames and bridges.

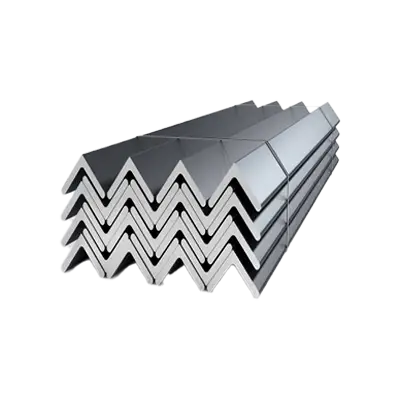

4. **Angle (L-Shaped):** Comprises two legs that form a 90-degree angle. It is used in bracing, framing, and as a support structure.

5. **Tee (T-Shaped):** Resembles the letter T and is used in load-bearing applications. It is often used in manufacturing and construction.

6. **Pipe:** Circular in cross-section, used for structural purposes and as conduits for fluids. They are known for their ability to withstand pressure.

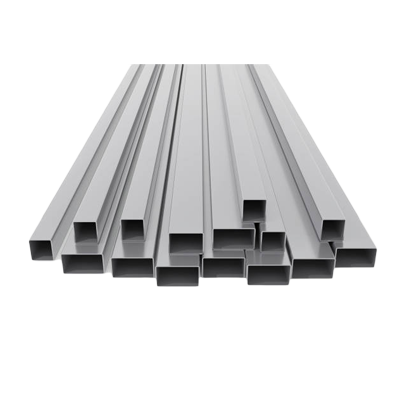

7. **Tube (Hollow Structural Section - HSS):** Available in square, rectangular, and circular shapes. They are used in welded steel frames and are known for their aesthetic appeal and strength.

8. **Flat Bar:** A flat, rectangular section used in a variety of applications, including braces, supports, and frames.

9. **Plate:** A flat, thick piece of steel used in structural applications, often as a base plate or gusset plate.

10. **Z-Shape:** Features a Z-shaped cross-section and is used in roofing and siding applications.

These shapes are selected based on the specific requirements of the project, including load-bearing capacity, aesthetic considerations, and construction methods.

What are the advantages of using structural steel in construction?

Structural steel offers several advantages in construction:

1. **Strength and Durability**: Structural steel is known for its high strength-to-weight ratio, making it ideal for large-scale structures. It can withstand significant stress and pressure, ensuring longevity and stability.

2. **Flexibility and Versatility**: Steel can be molded into various shapes and sizes, allowing for innovative architectural designs. Its versatility makes it suitable for a wide range of applications, from skyscrapers to bridges.

3. **Speed of Construction**: Prefabricated steel components can be quickly assembled on-site, reducing construction time. This efficiency can lead to cost savings and faster project completion.

4. **Cost-Effectiveness**: Although the initial cost of steel may be higher than some materials, its durability and low maintenance requirements can result in long-term savings. Steel structures also have a high salvage value.

5. **Sustainability**: Steel is 100% recyclable, making it an environmentally friendly choice. It can be reused without loss of quality, reducing the carbon footprint of construction projects.

6. **Fire Resistance**: With proper treatment, structural steel can offer excellent fire resistance, enhancing the safety of buildings. Fireproofing materials can be applied to steel to meet safety standards.

7. **Seismic Resistance**: Steel's ductility allows it to absorb and dissipate energy during seismic events, making it a preferred material in earthquake-prone areas.

8. **Precision and Quality Control**: Steel components are manufactured under controlled conditions, ensuring high precision and quality. This reduces the likelihood of errors during construction.

9. **Adaptability**: Steel structures can be easily modified or expanded, accommodating future changes in building use or design.

These advantages make structural steel a popular choice in modern construction, offering a combination of strength, efficiency, and sustainability.

How is structural steel manufactured?

Structural steel is manufactured through a series of processes:

1. **Raw Material Preparation**: Iron ore, coal, and limestone are the primary raw materials. Iron ore is mined and processed to remove impurities. Coal is converted into coke, and limestone acts as a flux.

2. **Blast Furnace**: The raw materials are fed into a blast furnace. The coke burns to produce carbon monoxide, which reduces the iron ore to molten iron. Limestone helps remove impurities, forming slag.

3. **Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF)**: The molten iron is transferred to a BOF, where pure oxygen is blown through it to reduce carbon content, or to an EAF, where scrap steel is melted using electric arcs. Both methods produce molten steel.

4. **Secondary Refining**: The molten steel undergoes further refining to adjust its chemical composition and remove impurities. This may involve processes like degassing, desulfurization, and alloying.

5. **Continuous Casting**: The refined molten steel is cast into semi-finished shapes like slabs, blooms, or billets through continuous casting. The steel solidifies as it cools.

6. **Hot Rolling**: The semi-finished shapes are heated and passed through rolling mills to form structural shapes like beams, channels, and angles. This process refines the grain structure and improves mechanical properties.

7. **Cooling and Cutting**: The rolled steel is cooled and cut to desired lengths. Controlled cooling can enhance specific properties like strength and toughness.

8. **Surface Treatment**: The steel may undergo surface treatments such as galvanizing or painting to enhance corrosion resistance.

9. **Quality Control**: Throughout the process, rigorous quality control measures ensure the steel meets required standards and specifications.

10. **Distribution**: The finished structural steel is then distributed to construction sites or manufacturers for use in building and infrastructure projects.

What are the common grades of structural steel?

Common grades of structural steel include:

1. **ASTM A36**: Widely used in construction, it offers good weldability and machinability. It is suitable for bolted, riveted, or welded structures.

2. **ASTM A572**: Available in grades 42, 50, 55, 60, and 65, it provides high strength and is used in bridges, buildings, and other structural applications.

3. **ASTM A992**: Predominantly used in the United States for wide-flange beams, it offers improved weldability and is often used in building frames.

4. **EN 10025 S275**: A European standard, it is used in construction and offers good weldability and machinability.

5. **EN 10025 S355**: Known for its high strength, it is used in construction and engineering applications, available in grades like S355JR, S355J0, and S355J2.

6. **EN 10025 S235**: A lower strength grade than S275 and S355, it is used in less demanding applications.

7. **BS 4360**: A British standard, it includes grades like 43A, 50B, and 55C, used in structural applications.

8. **JIS G3101 SS400**: A Japanese standard, it is used in general structural applications and offers good weldability.

9. **CSA G40.21**: A Canadian standard, it includes grades like 44W, 50W, and 50A, used in construction and engineering.

10. **IS 2062**: An Indian standard, it includes grades like E250, E350, and E410, used in structural applications.

These grades vary in terms of yield strength, tensile strength, and composition, making them suitable for different structural applications.

How does structural steel compare to other building materials like concrete or wood?

Structural steel offers several advantages over concrete and wood. It has a high strength-to-weight ratio, allowing for lighter structures and longer spans, which can reduce foundation costs and increase usable space. Steel is also highly ductile, providing excellent performance under dynamic loads such as wind or earthquakes, and it can be easily prefabricated, reducing construction time and labor costs.

In contrast, concrete is known for its compressive strength and durability. It is fire-resistant and can be molded into various shapes, making it versatile for different architectural designs. However, concrete structures are generally heavier, which can increase foundation requirements and construction time. Concrete also requires formwork and curing, which can add to labor and time costs.

Wood is a renewable resource and offers aesthetic and environmental benefits. It is lightweight and easy to work with, making it suitable for residential and low-rise buildings. However, wood is less durable than steel and concrete, being susceptible to fire, pests, and moisture-related issues. It also has lower strength, limiting its use in high-rise or heavy-load structures.

Steel is recyclable, contributing to sustainability, but it can be prone to corrosion if not properly maintained. Concrete has a high carbon footprint due to cement production, but innovations like carbon capture and alternative cements are addressing this. Wood is the most sustainable in terms of carbon sequestration, but responsible sourcing is crucial to prevent deforestation.

Overall, the choice between these materials depends on factors like structural requirements, environmental conditions, budget, and sustainability goals. Each material has its own set of advantages and limitations, making them suitable for different types of projects.

What are the standards and specifications for structural steel?

Structural steel standards and specifications ensure quality, safety, and consistency in construction. Key standards include:

1. **ASTM International (American Society for Testing and Materials):**

- **ASTM A36/A36M:** Standard for carbon structural steel.

- **ASTM A992/A992M:** Specification for steel wide-flange shapes for use in building framing.

- **ASTM A572/A572M:** High-strength low-alloy columbium-vanadium structural steel.

2. **AISC (American Institute of Steel Construction):**

- **AISC 360:** Specification for structural steel buildings, covering design, fabrication, and erection.

- **AISC 341:** Seismic provisions for structural steel buildings.

3. **EN (European Norms):**

- **EN 10025:** Specification for hot-rolled products of structural steels.

- **EN 1993 (Eurocode 3):** Design of steel structures, providing comprehensive guidelines for structural design.

4. **BSI (British Standards Institution):**

- **BS 5950:** Structural use of steelwork in building.

- **BS EN 1090:** Execution of steel structures and aluminum structures.

5. **CSA (Canadian Standards Association):**

- **CSA G40.21:** General requirements for rolled or welded structural quality steel.

- **CSA S16:** Design of steel structures.

6. **IS (Indian Standards):**

- **IS 2062:** Hot rolled medium and high tensile structural steel.

- **IS 800:** General construction in steel, code of practice.

These standards cover material properties, dimensions, tolerances, testing methods, and design criteria, ensuring that structural steel components meet necessary performance and safety requirements.

How is structural steel recycled and what are its environmental benefits?

Structural steel is recycled through a process that involves collection, sorting, shredding, melting, and reforming. First, steel is collected from demolition sites, scrap yards, and manufacturing waste. It is then sorted to separate it from other materials. The sorted steel is shredded into smaller pieces to facilitate melting. These pieces are melted in an electric arc furnace, which uses high temperatures to liquefy the steel. Impurities are removed during this process, and alloying elements may be added to achieve desired properties. The molten steel is then cast into new shapes, such as beams or bars, and cooled for reuse in construction and manufacturing.

The environmental benefits of recycling structural steel are significant. Recycling steel reduces the need for raw material extraction, conserving natural resources like iron ore, coal, and limestone. It also decreases energy consumption, as recycling steel uses about 60-74% less energy compared to producing new steel from raw materials. This reduction in energy use leads to lower greenhouse gas emissions, helping to mitigate climate change. Additionally, recycling steel minimizes landfill waste, as steel is diverted from disposal sites and reused. The process also reduces air and water pollution associated with mining and processing raw materials. Overall, recycling structural steel contributes to a more sustainable construction industry by conserving resources, reducing emissions, and minimizing environmental impact.