Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What are end mills used for?

End mills are cutting tools used in milling applications, primarily in the manufacturing and metalworking industries. They are designed to remove material from a workpiece by advancing into the material in a variety of directions, unlike drill bits which can only cut axially. End mills are used for a wide range of operations, including:

1. **Profiling**: Creating complex shapes and contours on a workpiece. End mills can move in multiple axes, allowing for intricate designs and detailed surface finishes.

2. **Slotting**: Cutting slots or grooves into a material. This is often used in the creation of keyways or channels.

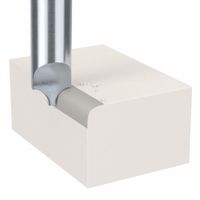

3. **Plunging**: Unlike drill bits, end mills can plunge directly into the material, making them suitable for creating pockets or cavities.

4. **Face Milling**: Producing a flat surface on the workpiece. End mills can be used to achieve a smooth finish on the face of a material.

5. **Contour Milling**: Following the outline of a part to create a specific shape or profile. This is often used in the production of complex parts.

6. **Chamfering**: Creating beveled edges on a workpiece. End mills can be used to add chamfers to parts for aesthetic or functional purposes.

7. **Reaming and Boring**: Enlarging or finishing holes to precise dimensions. End mills can refine the size and finish of pre-drilled holes.

End mills come in various shapes, sizes, and materials, including high-speed steel, carbide, and cobalt, each suited for different materials and applications. They can have different flute designs, such as two-flute, four-flute, or variable flute, which affect the cutting action and finish. The versatility and precision of end mills make them essential tools in CNC machining and other milling operations.

How do I choose the right end mill for my project?

1. **Material**: Match the end mill material to the workpiece. Use high-speed steel (HSS) for softer materials, carbide for harder materials, and coatings like TiN or TiAlN for increased durability and heat resistance.

2. **End Mill Type**: Choose between square end mills for flat-bottomed cuts, ball nose end mills for rounded cuts, and corner radius end mills for a blend of both. Use roughing end mills for fast material removal and finishing end mills for fine surface finishes.

3. **Flute Count**: Select fewer flutes (2-3) for softer materials and better chip evacuation. Use more flutes (4-6) for harder materials and smoother finishes.

4. **Helix Angle**: A higher helix angle (40°-60°) provides a smoother finish and is better for harder materials, while a lower angle (30°) is suitable for softer materials and aggressive cutting.

5. **Coating**: Consider coatings like TiN, TiCN, or TiAlN for increased tool life and performance, especially in high-speed or high-temperature applications.

6. **Size and Length**: Choose the appropriate diameter and length based on the depth and width of the cut. Larger diameters provide more rigidity, while longer lengths offer deeper reach but may reduce stability.

7. **Shank Type**: Ensure the shank type (straight or tapered) matches your machine's collet or holder for secure mounting.

8. **Machine Capability**: Match the end mill to your machine's capabilities, considering spindle speed, feed rate, and horsepower.

9. **Application**: Consider the specific application, such as slotting, profiling, or contouring, and choose an end mill designed for that purpose.

10. **Budget**: Balance cost with performance needs. Higher-quality end mills may have a higher upfront cost but offer longer tool life and better results.

What is the difference between a ball end mill and a square end mill?

A ball end mill and a square end mill are both types of cutting tools used in milling operations, but they have distinct differences in design and application.

A ball end mill features a hemispherical cutting tip. This design allows it to create rounded profiles, contours, and 3D shapes. It is particularly useful for machining complex surfaces, such as molds and dies, where smooth, curved surfaces are required. The ball end mill is also effective in reducing stress concentration, which can be beneficial in applications involving high-stress components. Its geometry allows for a more gradual engagement with the material, which can result in a smoother finish and less tool wear.

In contrast, a square end mill has a flat cutting tip with sharp corners. This design is ideal for creating flat surfaces, sharp edges, and 90-degree corners. It is commonly used for slotting, profiling, and finishing operations where precise, straight edges are needed. The square end mill is versatile and can be used for a wide range of materials and applications, making it a staple in many machining operations.

The choice between a ball end mill and a square end mill depends on the specific requirements of the machining task. For applications requiring smooth, contoured surfaces, a ball end mill is preferred. For tasks needing precise, flat surfaces and sharp edges, a square end mill is more suitable. Each type of end mill has its own advantages and is selected based on the desired outcome of the milling process.

How do I maintain and care for end mills?

To maintain and care for end mills, follow these steps:

1. **Proper Storage**: Store end mills in a clean, dry environment. Use protective cases or holders to prevent damage and contamination. Ensure they are organized by size and type for easy access.

2. **Regular Inspection**: Frequently inspect end mills for wear, chipping, or damage. Check the cutting edges and shank for any signs of deterioration. Replace or regrind dull or damaged tools to maintain cutting efficiency.

3. **Cleaning**: After use, clean end mills thoroughly to remove chips, debris, and coolant residues. Use a soft brush or compressed air to clean the flutes and cutting edges. Avoid using harsh chemicals that may damage the tool.

4. **Lubrication**: Apply a light coat of rust-preventive oil to the end mills before storage to protect against corrosion. Ensure the oil is compatible with the tool material.

5. **Proper Usage**: Use end mills within their specified parameters, including speed, feed rate, and material compatibility. Avoid excessive heat and stress by using appropriate coolant and cutting conditions.

6. **Sharpening**: Regularly sharpen end mills to maintain cutting performance. Use a professional sharpening service or a precision tool grinder. Ensure the correct angles and dimensions are maintained during sharpening.

7. **Tool Holders**: Use high-quality tool holders to ensure proper alignment and stability during machining. Regularly check and maintain the tool holders to prevent runout and vibration.

8. **Training**: Ensure operators are trained in the correct handling and usage of end mills. Proper technique can significantly extend tool life and improve machining quality.

By following these maintenance and care practices, you can extend the life of your end mills and ensure optimal performance in machining operations.

What materials can end mills cut?

End mills are versatile cutting tools used in milling applications to remove material from a workpiece. They can cut a wide range of materials, including:

1. **Metals**:

- **Steel**: End mills can cut various types of steel, including carbon steel, alloy steel, and stainless steel.

- **Aluminum**: Due to its softness, aluminum is easily machined with end mills, often requiring specific coatings to prevent material buildup.

- **Brass and Copper**: These softer metals are also suitable for end milling, often used in decorative and electrical applications.

- **Titanium**: Specialized end mills with appropriate coatings and geometries are used for this tough, heat-resistant metal.

- **Cast Iron**: End mills can efficiently cut cast iron, though the material's brittleness requires careful handling.

2. **Plastics**:

- **Acrylic and Polycarbonate**: End mills can cut through these clear plastics, often used in prototyping and display applications.

- **Nylon and Delrin**: These engineering plastics are commonly machined with end mills for mechanical components.

3. **Composites**:

- **Fiberglass and Carbon Fiber**: Specialized end mills with specific geometries and coatings are used to cut these abrasive materials without fraying.

4. **Wood**:

- End mills can be used to cut various types of wood, from softwoods like pine to hardwoods like oak, often in cabinetry and furniture making.

5. **Ceramics and Glass**:

- While more challenging, certain end mills with diamond coatings can cut these brittle materials, typically in specialized applications.

End mills are selected based on the material's hardness, abrasiveness, and thermal properties, with considerations for tool geometry, coating, and cutting speed to optimize performance and tool life.

How do I determine the correct speed and feed rate for end mills?

To determine the correct speed and feed rate for end mills, consider the following factors:

1. **Material**: Identify the material of the workpiece. Different materials require different speeds and feeds. For example, aluminum typically allows for higher speeds compared to steel.

2. **Tool Material**: Consider the material of the end mill (e.g., high-speed steel, carbide). Carbide tools can generally handle higher speeds.

3. **Tool Diameter**: Larger diameter tools require slower speeds but can handle higher feed rates.

4. **Cutting Speed (SFM)**: Use the formula: SFM = (π × Diameter × RPM) / 12. Reference material-specific SFM charts to find the recommended SFM for your material and tool.

5. **RPM Calculation**: Calculate the spindle speed (RPM) using: RPM = (SFM × 12) / (π × Diameter).

6. **Feed Rate**: Determine the feed rate using: Feed Rate = RPM × Number of Flutes × Chip Load. Chip load is the thickness of the material removed by each cutting edge per revolution, found in manufacturer charts.

7. **Depth of Cut**: Consider the axial and radial depth of cut. Deeper cuts require slower speeds and feeds.

8. **Machine Capability**: Ensure the machine can handle the calculated speeds and feeds without excessive vibration or load.

9. **Coolant Use**: Use coolant to reduce heat and improve tool life, especially at higher speeds.

10. **Trial and Adjustment**: Start with conservative values and adjust based on tool wear, surface finish, and machine performance.

11. **Software and Calculators**: Utilize CNC software or online calculators for precise calculations based on specific parameters.

By considering these factors and using the appropriate formulas and charts, you can determine the optimal speed and feed rate for your end milling operation.

What are the different types of end mills and their applications?

End mills are cutting tools used in milling applications, and they come in various types, each designed for specific tasks:

1. **Square End Mills**: These have a flat bottom and are used for general-purpose milling, including slotting, profiling, and plunge cutting.

2. **Ball Nose End Mills**: Featuring a rounded tip, these are ideal for 3D contouring and machining complex surfaces, such as molds and dies.

3. **Corner Radius End Mills**: These have rounded edges, which reduce chipping and extend tool life, making them suitable for roughing and finishing operations.

4. **Roughing End Mills**: Also known as hog mills, they have serrated cutting edges for rapid material removal in heavy-duty milling tasks.

5. **Finishing End Mills**: Designed for fine surface finishes, these have a smooth cutting edge and are used after roughing operations.

6. **Tapered End Mills**: With a conical shape, these are used for machining angled surfaces and are common in die and mold making.

7. **Chamfer End Mills**: These create beveled edges or chamfers on a workpiece, useful for deburring and edge finishing.

8. **Double-End End Mills**: Featuring cutting edges on both ends, they offer cost efficiency by doubling the tool life.

9. **Single Flute End Mills**: With one cutting edge, they are ideal for high-speed machining of soft materials like aluminum.

10. **Multi-Flute End Mills**: With more than two flutes, these provide a smoother finish and are used for finishing operations on harder materials.

11. **Carbide End Mills**: Made from carbide, they offer high wear resistance and are suitable for high-speed applications.

12. **High-Speed Steel (HSS) End Mills**: These are versatile and cost-effective, used for general-purpose milling in softer materials.

Each type of end mill is selected based on the material being machined, the desired finish, and the specific milling operation required.