.....Read More

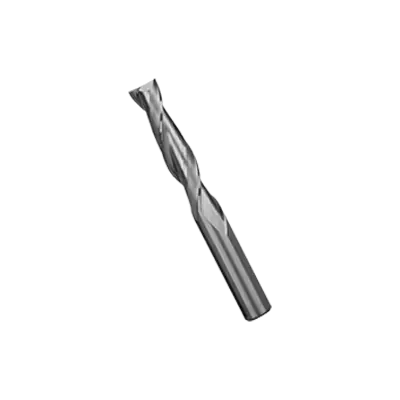

Cobalt Corner-Radius End Mills

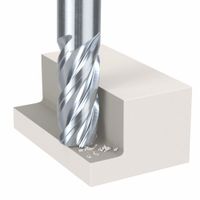

General Purpose Finishing Bright Finish Carbide Corner-Radius End Mills

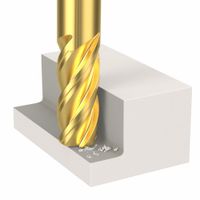

General Purpose Finishing Coated Carbide Corner-Radius End Mills

General Purpose Roughing Carbide Corner-Radius End Mills

General Purpose Roughing/Finishing Carbide Corner-Radius End Mills

High-Performance Finishing Bright Finish Carbide Corner-Radius End Mills

High-Performance Finishing Coated Carbide Corner-Radius End Mills

High-Performance Roughing Carbide Corner-Radius End Mills

High-Performance Roughing/Finishing Bright Finish Carbide Corner-Radius End Mills

High-Performance Roughing/Finishing Coated Carbide Corner-Radius End Mills

High-Speed Steel Corner-Radius End Mills

Powdered-Metal Corner-Radius End Mills

Frequently Asked Questions

What is a corner-radius end mill used for?

How does a corner-radius end mill differ from a standard end mill?

What materials can be machined with corner-radius end mills?

How do you select the right corner radius for an end mill?

What are the benefits of using a corner-radius end mill?

How do you maintain and care for corner-radius end mills?

What are the common sizes and specifications for corner-radius end mills?