.....Read More

Miniature CBN Ball End Mills

Miniature Cobalt Ball End Mills

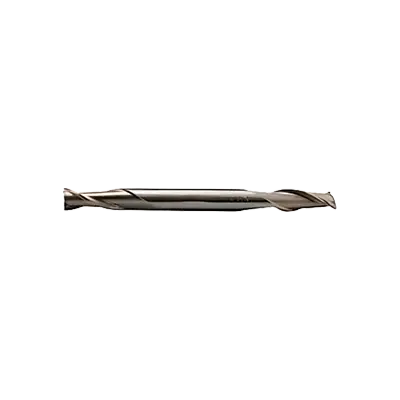

Miniature Cobalt Square End Mills

Miniature Corner-Chamfer End Mills

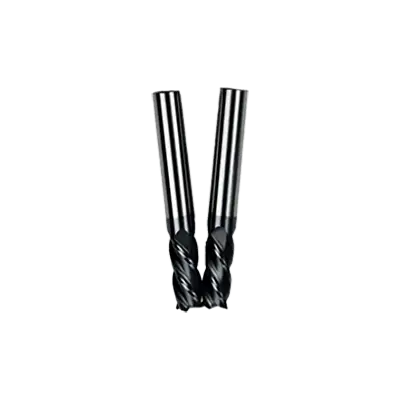

Miniature General Purpose Carbide Ball End Mills

Miniature General Purpose Carbide Corner-Radius End Mills

Miniature General Purpose Carbide Square End Mills

Miniature General Purpose High-Speed Steel Square End Mills

Miniature High-Performance Carbide Ball End Mills

Miniature High-Performance Carbide Corner-Radius End Mills

Miniature High-Performance Carbide Square End Mills

Miniature High-Performance High-Speed Steel Square End Mills

Miniature High-Speed Steel Ball End Mills

Miniature Powdered-Metal Square End Mills

Frequently Asked Questions

What are miniature end mills used for?

How do miniature end mills differ from regular end mills?

What materials can be machined with miniature end mills?

How do you choose the right miniature end mill for a project?

What are the advantages of using miniature end mills?

How do you maintain and care for miniature end mills?

What are the common sizes and types of miniature end mills available?