Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Metals

- Stainless Steel

.....Read More

Frequently Asked Questions

What are the different grades of stainless steel?

Stainless steel grades are categorized based on their composition and properties, primarily focusing on corrosion resistance, strength, and formability. The main grades include:

1. **Austenitic Stainless Steel**:

- **300 Series**: Most common, includes 304 and 316.

- **304**: Contains 18% chromium and 8% nickel, offering excellent corrosion resistance and formability.

- **316**: Similar to 304 but with 2-3% molybdenum for enhanced corrosion resistance, especially against chlorides.

- **200 Series**: Lower nickel content, often replaced with manganese and nitrogen, less corrosion-resistant than 300 series.

2. **Ferritic Stainless Steel**:

- **400 Series**: Includes grades like 430 and 409.

- **430**: Contains 17% chromium, good corrosion resistance, and formability, often used in automotive and appliance applications.

- **409**: Contains 11% chromium, used in automotive exhaust systems due to its high-temperature resistance.

3. **Martensitic Stainless Steel**:

- **400 Series**: Includes grades like 410 and 420.

- **410**: Contains 12% chromium, offers high strength and moderate corrosion resistance, used in cutlery and tools.

- **420**: Higher carbon content than 410, used for surgical instruments and cutlery.

4. **Duplex Stainless Steel**:

- Combines austenitic and ferritic properties, offering high strength and excellent corrosion resistance. Common grades include 2205 and 2507.

5. **Precipitation-Hardening Stainless Steel**:

- Known for high strength and hardness, includes grades like 17-4 PH, used in aerospace and other high-performance applications.

6. **Specialty Grades**:

- Include high-alloyed stainless steels for specific applications, such as super austenitic and super duplex grades, offering superior corrosion resistance in extreme environments.

How does stainless steel resist corrosion?

Stainless steel resists corrosion primarily due to the presence of chromium, which constitutes at least 10.5% of its composition. When exposed to oxygen, chromium forms a thin, stable layer of chromium oxide on the surface of the steel. This passive film acts as a protective barrier, preventing further oxidation and corrosion of the underlying metal. Unlike iron oxide, which flakes off and exposes fresh metal to corrosion, chromium oxide adheres tightly to the surface, effectively sealing it from environmental factors.

The self-healing nature of this passive layer is crucial. If the surface is scratched or damaged, the exposed chromium reacts with oxygen to quickly reform the protective oxide layer, maintaining the steel's resistance to corrosion. This process is known as passivation.

Other alloying elements, such as nickel, molybdenum, and nitrogen, can enhance the corrosion resistance of stainless steel. Nickel stabilizes the austenitic structure, improving toughness and resistance to acidic environments. Molybdenum increases resistance to pitting and crevice corrosion, particularly in chloride-rich environments like seawater. Nitrogen enhances mechanical strength and further improves resistance to pitting.

The specific type of stainless steel and its resistance to corrosion depend on its composition and the environment in which it is used. For instance, austenitic stainless steels, such as the 300 series, are highly resistant to corrosion and are commonly used in food processing and medical equipment. Ferritic and martensitic stainless steels, with lower chromium content, offer moderate resistance and are used in applications like automotive exhausts and cutlery.

Overall, the combination of chromium and other alloying elements, along with the self-repairing passive film, enables stainless steel to maintain its integrity and appearance in a wide range of corrosive environments.

What are the applications of stainless steel sheets and plates?

Stainless steel sheets and plates are versatile materials used across various industries due to their durability, corrosion resistance, and aesthetic appeal. In the construction industry, they are employed for structural components, roofing, and cladding, providing both strength and a modern look. In the automotive sector, stainless steel is used for manufacturing exhaust systems, trim, and structural components, offering resistance to heat and corrosion.

In the food and beverage industry, stainless steel sheets and plates are essential for manufacturing equipment like tanks, countertops, and processing machinery, ensuring hygiene and ease of cleaning. The chemical and petrochemical industries utilize them for storage tanks, pipelines, and heat exchangers due to their ability to withstand harsh chemicals and high temperatures.

In the medical field, stainless steel is used for surgical instruments, implants, and hospital equipment, benefiting from its non-reactive and easy-to-sterilize nature. The aerospace industry employs stainless steel for components that require high strength and resistance to extreme temperatures and pressures.

In the energy sector, stainless steel sheets and plates are used in the construction of power plants, including nuclear reactors, due to their ability to endure high stress and corrosive environments. Additionally, they are used in the production of renewable energy systems, such as solar panels and wind turbines.

In the realm of consumer goods, stainless steel is popular for kitchen appliances, cookware, and cutlery, valued for its aesthetic appeal and durability. Lastly, in the art and architecture fields, stainless steel is used for sculptures and decorative elements, offering a sleek, modern finish that withstands the elements.

How is stainless steel tubing used in construction?

Stainless steel tubing is extensively used in construction due to its durability, corrosion resistance, and aesthetic appeal. It is employed in structural applications, such as in the framework of buildings, bridges, and other infrastructure, where its strength and ability to withstand harsh environmental conditions are crucial. Stainless steel tubing is also used in architectural elements, including handrails, balustrades, and facades, providing both functional support and a modern, sleek appearance.

In plumbing and piping systems, stainless steel tubing is favored for its resistance to corrosion and ability to handle high temperatures and pressures, making it ideal for transporting water, gas, and other fluids. Its hygienic properties make it suitable for use in hospitals, laboratories, and food processing facilities.

Additionally, stainless steel tubing is used in HVAC systems for ductwork and exhausts, where its thermal conductivity and resistance to corrosion ensure efficient and long-lasting performance. In the construction of industrial facilities, it is used for process piping and equipment, where its strength and resistance to chemical exposure are essential.

The versatility of stainless steel tubing allows for its use in both interior and exterior applications, contributing to the longevity and sustainability of construction projects. Its recyclability further enhances its appeal in environmentally conscious construction practices. Overall, stainless steel tubing is a vital component in modern construction, offering a combination of strength, durability, and aesthetic value.

What are the benefits of using stainless steel in industrial machinery?

Stainless steel offers numerous benefits in industrial machinery, making it a preferred material in various applications. Its primary advantage is its exceptional corrosion resistance, which is crucial in environments exposed to moisture, chemicals, and other corrosive elements. This resistance extends the lifespan of machinery, reducing maintenance costs and downtime.

The material's high strength-to-weight ratio allows for the construction of robust yet lightweight components, enhancing the efficiency and performance of machinery. Stainless steel also maintains its strength at high temperatures, making it suitable for applications involving heat exposure.

Hygiene is another significant benefit, particularly in industries like food processing and pharmaceuticals. Stainless steel's non-porous surface is easy to clean and sterilize, preventing contamination and ensuring compliance with health standards.

Additionally, stainless steel is highly durable and resistant to wear and tear, which is essential for machinery subjected to constant use and mechanical stress. Its aesthetic appeal, with a sleek and modern finish, is a bonus in industries where appearance matters.

The material is also environmentally friendly, being 100% recyclable, which aligns with sustainable practices and reduces the environmental impact of industrial operations.

Finally, stainless steel's versatility allows it to be fabricated into various shapes and sizes, accommodating diverse industrial needs. Its compatibility with other materials and ability to be welded, machined, and formed further enhance its applicability in complex machinery designs.

Overall, the use of stainless steel in industrial machinery results in long-lasting, efficient, and reliable equipment, offering a balance of performance, safety, and cost-effectiveness.

How do you maintain and clean stainless steel surfaces?

To maintain and clean stainless steel surfaces, follow these steps:

1. **Regular Dusting**: Use a soft microfiber cloth to dust the surface regularly, preventing dirt accumulation.

2. **Gentle Cleaning**: For routine cleaning, use warm water and a soft cloth. Wipe in the direction of the grain to avoid scratches.

3. **Mild Detergent**: For more thorough cleaning, mix a few drops of mild dish soap with warm water. Apply with a soft cloth, then rinse with clean water and dry immediately to prevent water spots.

4. **Vinegar Solution**: For fingerprints and smudges, mix equal parts of water and white vinegar in a spray bottle. Spray onto the surface, wipe with a microfiber cloth, and dry.

5. **Baking Soda Paste**: For stubborn stains, make a paste of baking soda and water. Apply gently with a soft cloth, rinse, and dry.

6. **Commercial Cleaners**: Use stainless steel cleaners or polishes for a shiny finish. Follow the product instructions and always wipe in the grain's direction.

7. **Avoid Abrasives**: Never use steel wool, abrasive pads, or harsh chemicals like bleach, as they can scratch and damage the surface.

8. **Rinse and Dry**: Always rinse thoroughly with clean water after cleaning to remove any residue, and dry with a soft cloth to prevent water spots.

9. **Polishing**: Occasionally, apply a small amount of olive oil or a specialized stainless steel polish to a cloth and buff the surface to enhance shine and protect against fingerprints.

10. **Preventive Measures**: Use coasters, mats, or trivets to protect surfaces from heat and scratches. Regularly inspect and address any signs of rust or damage promptly.

By following these steps, you can maintain the appearance and longevity of stainless steel surfaces.

What are the differences between stainless steel bars, rods, and discs?

Stainless steel bars, rods, and discs differ primarily in shape, application, and manufacturing processes.

**Shape and Dimensions:**

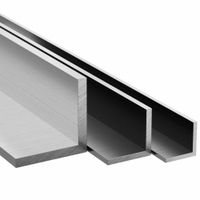

- **Bars:** Typically have a rectangular or square cross-section. They come in various lengths and thicknesses, often used in construction and structural applications.

- **Rods:** Generally have a circular cross-section. They are long and cylindrical, used in applications requiring precision and strength, such as in machinery and automotive components.

- **Discs:** Flat and circular, discs are often used in applications requiring a flat surface, such as in flanges, valves, and fittings.

**Applications:**

- **Bars:** Used in construction, infrastructure, and heavy machinery. They provide structural support and are often used in frameworks, bridges, and buildings.

- **Rods:** Common in manufacturing, machining, and as fasteners. They are used in shafts, spindles, and as reinforcement in concrete.

- **Discs:** Utilized in manufacturing processes that require circular components. They are often used in the production of gaskets, seals, and as base plates.

**Manufacturing Processes:**

- **Bars and Rods:** Typically produced through hot rolling, cold drawing, or extrusion. The choice of process affects the mechanical properties and surface finish.

- **Discs:** Often cut from larger sheets or plates using methods like laser cutting, water jet cutting, or stamping, ensuring precision in diameter and thickness.

**Material Properties:**

All three forms share the inherent properties of stainless steel, such as corrosion resistance, strength, and durability. However, the specific grade of stainless steel used can vary based on the intended application, affecting properties like hardness and machinability.

In summary, while bars, rods, and discs are all made from stainless steel, their differences lie in their shape, specific applications, and the processes used to manufacture them.