Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Metals

- Stainless Steel

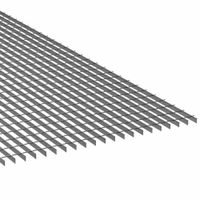

- Stainless Steel Grating Stair Treads

.....Read More

Frequently Asked Questions

What are the benefits of using stainless steel grating in industrial settings?

Stainless steel grating offers numerous benefits in industrial settings:

1. **Corrosion Resistance**: Stainless steel is highly resistant to corrosion, making it ideal for environments exposed to moisture, chemicals, and other corrosive elements. This ensures longevity and reduces maintenance costs.

2. **Durability**: It is known for its strength and durability, capable of withstanding heavy loads and harsh conditions without deforming or breaking.

3. **Hygiene**: Stainless steel is easy to clean and does not harbor bacteria, making it suitable for industries like food processing and pharmaceuticals where hygiene is critical.

4. **Aesthetic Appeal**: It provides a sleek, modern look, which can be important in settings where appearance matters, such as public spaces or commercial facilities.

5. **Temperature Resistance**: Stainless steel can withstand extreme temperatures, both hot and cold, making it versatile for various industrial applications.

6. **Non-slip Surface**: Many stainless steel gratings are designed with a non-slip surface, enhancing safety by reducing the risk of slips and falls in wet or oily conditions.

7. **Low Maintenance**: Its resistance to rust and staining means it requires minimal maintenance, saving time and costs over its lifespan.

8. **Recyclability**: Stainless steel is 100% recyclable, making it an environmentally friendly choice that supports sustainability initiatives.

9. **Versatility**: Available in various sizes, shapes, and configurations, stainless steel grating can be customized to fit specific industrial needs, from flooring to drainage systems.

10. **Fire Resistance**: It does not combust, adding an extra layer of safety in environments where fire hazards are a concern.

These benefits make stainless steel grating a preferred choice in many industrial applications, offering a combination of performance, safety, and cost-effectiveness.

How do you install stainless steel stair treads?

1. **Measure and Plan**: Determine the dimensions of the stairs and the number of treads needed. Ensure the treads fit the width and depth of each step.

2. **Prepare the Surface**: Clean the existing stair surface thoroughly to remove dirt, grease, or debris. Ensure the surface is dry and smooth.

3. **Cut the Treads**: If necessary, cut the stainless steel treads to fit the dimensions of each step using a metal cutting saw or grinder. Wear safety gear during this process.

4. **Drill Holes**: Mark and drill holes in the treads for screws or bolts, ensuring they align with the stair structure. Use a drill bit suitable for metal.

5. **Position the Treads**: Place the treads on the stairs, ensuring they are centered and aligned properly. Use a level to check for evenness.

6. **Secure the Treads**: Attach the treads using stainless steel screws or bolts. Tighten them securely to prevent movement. If using adhesive, apply a high-strength construction adhesive to the underside of the treads before positioning them.

7. **Seal the Edges**: Apply a silicone sealant around the edges of the treads to prevent moisture ingress and provide a finished look.

8. **Check Stability**: Ensure each tread is firmly attached and does not shift. Walk on the stairs to test stability and make any necessary adjustments.

9. **Finish and Clean**: Wipe down the treads with a stainless steel cleaner to remove fingerprints and debris. Polish for a shiny finish.

10. **Regular Maintenance**: Periodically check the treads for any signs of wear or loosening and clean them regularly to maintain their appearance and safety.

What are the differences between serrated and smooth surface stainless steel grating?

Serrated and smooth surface stainless steel gratings differ primarily in texture, application, and safety features.

1. **Texture**:

- **Serrated Grating**: Features a series of notches or teeth on the surface, providing a rough texture.

- **Smooth Grating**: Has a flat, even surface without any additional texture.

2. **Slip Resistance**:

- **Serrated Grating**: Offers enhanced slip resistance due to its textured surface, making it ideal for environments where safety is a concern, such as wet or oily conditions.

- **Smooth Grating**: Provides less traction, suitable for areas where slip resistance is not a primary concern.

3. **Applications**:

- **Serrated Grating**: Commonly used in industrial settings, such as factories, oil rigs, and outdoor walkways, where slip hazards are prevalent.

- **Smooth Grating**: Often used in areas where aesthetics are important, such as architectural applications, or where the grating is not exposed to slippery substances.

4. **Maintenance**:

- **Serrated Grating**: May require more frequent cleaning to remove debris that can accumulate in the notches.

- **Smooth Grating**: Easier to clean due to its flat surface, reducing maintenance efforts.

5. **Cost**:

- **Serrated Grating**: Typically more expensive due to the additional manufacturing process required to create the serrations.

- **Smooth Grating**: Generally less costly, as it involves a simpler production process.

6. **Load Bearing**:

- Both types can be designed to handle various load requirements, but the choice between serrated and smooth often depends on the specific environmental and safety needs rather than load capacity alone.

How do you maintain and clean stainless steel grating and stair treads?

To maintain and clean stainless steel grating and stair treads, follow these steps:

1. **Regular Cleaning**: Use a soft brush or broom to remove loose debris and dirt. For routine cleaning, wash with warm water and a mild detergent. Rinse thoroughly with clean water to prevent residue buildup.

2. **Stain Removal**: For stubborn stains, use a mixture of baking soda and water to form a paste. Apply it to the stain, let it sit for a few minutes, then scrub gently with a non-abrasive pad. Rinse thoroughly.

3. **Grease and Oil**: Use a degreaser or a solution of vinegar and water to tackle grease and oil. Apply the solution, scrub with a soft brush, and rinse well.

4. **Rust and Corrosion**: Use a commercial stainless steel cleaner or a mixture of lemon juice and baking soda. Apply, scrub gently, and rinse. For severe rust, consider using a stainless steel passivation product.

5. **Polishing**: To restore shine, use a stainless steel polish or olive oil. Apply with a soft cloth, buff in the direction of the grain, and wipe off excess.

6. **Preventive Measures**: Regularly inspect for damage or wear. Ensure proper drainage to prevent water accumulation. Avoid using steel wool or abrasive cleaners that can scratch the surface.

7. **Environmental Considerations**: In corrosive environments, increase the frequency of cleaning and consider applying a protective coating.

8. **Safety**: Always wear gloves and protective eyewear when using chemical cleaners. Ensure adequate ventilation.

By following these steps, you can maintain the appearance and longevity of stainless steel grating and stair treads.

What are the standard sizes and dimensions for stainless steel grating and stair treads?

Standard sizes and dimensions for stainless steel grating and stair treads vary based on application and manufacturer specifications, but generally adhere to industry norms.

**Stainless Steel Grating:**

1. **Bar Spacing:** Common bar spacing includes 19-w-4 (19/16" on center) and 15-w-4 (15/16" on center).

2. **Load Bar Size:** Typically ranges from 1" to 3" in height and 1/8" to 1/4" in thickness.

3. **Panel Size:** Standard panel sizes are often 2' x 20' or 3' x 24', but custom sizes are available.

4. **Material Grade:** Common grades include 304 and 316 stainless steel for corrosion resistance.

**Stair Treads:**

1. **Width:** Standard widths range from 8" to 12", but can be customized.

2. **Length:** Typically matches the width of the stairway, often 24" to 48".

3. **Nosing:** Treads often include a nosing for safety, which can be plain or serrated.

4. **Thickness:** Usually 1" to 1.5" thick, depending on load requirements.

5. **Finish:** Available in mill finish, electro-polished, or custom finishes for aesthetic and functional purposes.

Both grating and stair treads are designed to meet specific load and safety standards, such as those set by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). Customization is common to meet specific project requirements, including load capacity, environmental conditions, and aesthetic preferences.

How do you choose the right clips for securing stainless steel grating?

To choose the right clips for securing stainless steel grating, consider the following factors:

1. **Grating Type**: Identify the type of grating (e.g., bar, plank, or expanded metal) as different types may require specific clips.

2. **Load Requirements**: Determine the load-bearing requirements. Heavier loads may necessitate stronger clips or additional clips for stability.

3. **Environmental Conditions**: Consider the environment where the grating will be installed. Corrosive environments may require clips made from materials like stainless steel or with protective coatings.

4. **Clip Material**: Choose clips made from materials compatible with stainless steel to prevent galvanic corrosion. Stainless steel clips are often preferred for their durability and corrosion resistance.

5. **Clip Design**: Select the appropriate clip design (e.g., saddle clips, hold-down clips, or J-clips) based on the grating and support structure. The design should ensure a secure fit and ease of installation.

6. **Fastening Method**: Decide on the fastening method (e.g., bolted, welded, or clamped). Bolted clips are common for easy installation and removal, while welded clips provide a permanent solution.

7. **Size and Fit**: Ensure the clips are the correct size for the grating bars and support structure. They should fit snugly without causing deformation.

8. **Installation Ease**: Consider clips that are easy to install and require minimal tools, especially for large projects or difficult-to-access areas.

9. **Compliance and Standards**: Ensure the clips meet relevant industry standards and regulations for safety and performance.

10. **Cost and Availability**: Balance cost with quality and availability. Opt for reputable manufacturers to ensure reliability.

By evaluating these factors, you can select the most suitable clips for securing stainless steel grating effectively.

What are the safety features of stainless steel stair treads?

Stainless steel stair treads offer several safety features:

1. **Slip Resistance**: Stainless steel treads often have textured surfaces, such as diamond plate or raised patterns, to enhance grip and reduce the risk of slipping, especially in wet or oily conditions.

2. **Durability**: Stainless steel is highly resistant to corrosion, wear, and impact, ensuring that the treads maintain their structural integrity and safety features over time, even in harsh environments.

3. **Load Bearing Capacity**: Stainless steel treads are designed to support significant weight, providing a stable and secure surface for foot traffic, which is crucial in both residential and commercial settings.

4. **Fire Resistance**: Stainless steel is non-combustible and can withstand high temperatures, offering an added layer of safety in case of fire by not contributing to the spread of flames.

5. **Hygienic Surface**: The smooth, non-porous surface of stainless steel is easy to clean and does not harbor bacteria or mold, contributing to a safer environment, particularly in food processing or healthcare facilities.

6. **Visibility**: Some stainless steel treads come with integrated nosing or contrasting strips to enhance visibility, reducing the risk of missteps or falls, especially in low-light conditions.

7. **Edge Protection**: The edges of stainless steel treads are often rounded or beveled to prevent injuries from sharp corners, enhancing safety for users.

8. **Customization**: Stainless steel treads can be customized with additional safety features like anti-slip coatings or integrated lighting, tailored to specific safety requirements.

9. **Compliance**: Many stainless steel stair treads are designed to meet safety standards and building codes, ensuring they provide adequate protection and performance in various applications.