- Home

- Pipe Hose Tube Fittings

- Pipe Pipe Fittings

- Standard Pipe Pipe Fittings

- Steel Iron Pipe Systems

.....Read More

Black Steel & Iron Pipe & Pipe Nipples

Butt Weld Uncoated Black Steel & Iron Pipe Fittings

Compression Zinc Galvanized Steel Pipe Fittings

Ductile Iron Service Saddles

Flanged Uncoated Black Steel & Iron Pipe Fittings

Grooved Ductile Iron Pipe Fittings & Flanges

Grooved Zinc Galvanized Steel Pipe Fittings

No Hub Uncoated Black Iron Pipe Fittings

Socket Weld Uncoated Black Steel & Iron Pipe Fittings

Threaded Uncoated Black Steel & Iron Pipe Fittings

Threaded x Socket Weld Uncoated Black Steel & Iron Pipe Fittings

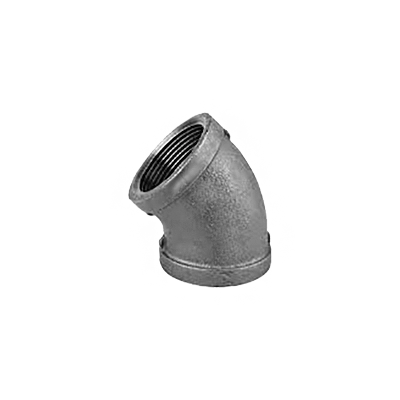

Threaded Zinc Galvanized Steel Pipe Fittings

Uncoated Alloy Steel (Chrome-Moly) Pipe Fittings

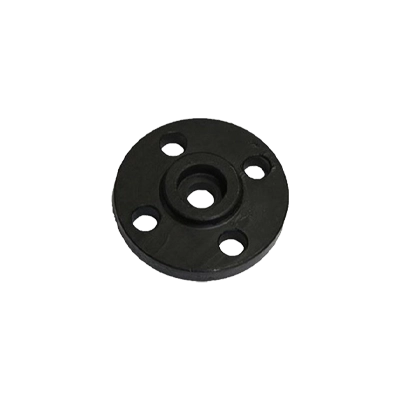

Uncoated Black Steel & Iron Pipe Flanges

Zinc Galvanized Pipe & Pipe Nipples

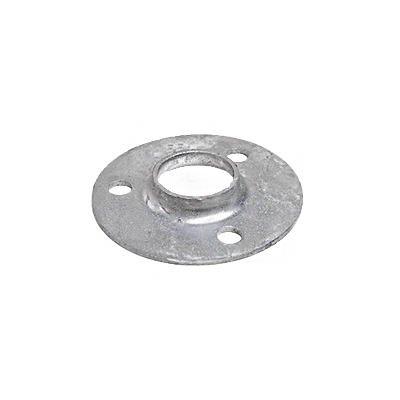

Zinc Galvanized Steel Pipe Flanges

Frequently Asked Questions

What is the difference between iron and steel?

How is steel made from iron?

What are the main uses of steel in construction?

What is black steel and how is it different from galvanized steel?

Why is ductile iron preferred over cast iron?

What are the advantages of using zinc galvanized steel?

How does chrome-moly steel compare to carbon steel in terms of strength?