Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

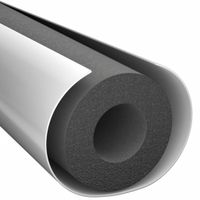

- Pipe Hose Tube Fittings

.....Read More

Frequently Asked Questions

What is the difference between a pipe, hose, and tube?

Pipes are rigid, typically used for structural applications or transporting fluids, gases, or slurries. Their dimensions are defined by nominal pipe size (NPS) and schedule for wall thickness. Hoses are flexible, reinforced, and often used for conveying fluids under pressure in dynamic applications, with dimensions based on inside diameter. Tubes are semi-rigid or flexible, characterized by their precise outside diameter and wall thickness, and are common in instrumentation, medical, and small-bore fluid transfer where exact sizing is critical. The key distinctions lie in their rigidity, typical applications, and how their sizes are measured.

How do I choose the right pipe fittings for my project?

Choosing the right pipe fittings depends on several factors. First, consider the material: PVC, copper, PEX, and steel each have different strengths for specific applications like plumbing, irrigation, or industrial use. Next, assess the pipe size and pressure requirements; fittings must match to ensure a secure, leak-free connection. The type of joint (threaded, soldered, crimped, or compression) is also crucial, impacting installation difficulty and needed tools. Finally, think about the environment—temperature, chemical exposure, and regulatory codes will guide your selection for safety and longevity.

What materials are best for pipes and hoses in plumbing?

For plumbing pipes, common materials include copper, known for its durability and corrosion resistance; PEX (cross-linked polyethylene), favored for its flexibility, ease of installation, and cost-effectiveness; and PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride), often used for drainage or cold-water lines due to their affordability and chemical resistance. For hoses, rubber and braided stainless steel are popular for their flexibility and pressure tolerance, commonly seen in supply lines for fixtures. The best material depends on specific application, water conditions, and local building codes.

How do I measure pipe or tube diameter accurately?

To accurately measure pipe or tube diameter, an outside caliper or a measuring tape is typically used. For precise internal diameter, a specialized bore gauge or an inside caliper is recommended. Ensure the measuring tool is perpendicular to the pipe's axis and take multiple readings across different points to account for any irregularities. For even greater accuracy, especially in industrial applications, consider using a laser micrometer or a ultrasonic thickness gauge, which can provide non-contact and highly reliable measurements of both internal and external diameters.

What are the common types of pipe fittings and their uses?

Common pipe fittings include elbows for changing direction, tees for splitting flow, reducers for changing pipe size, couplings for connecting pipes, and caps/plugs for sealing ends. They are used in plumbing, HVAC, and industrial systems to create complete pipelines for fluid or gas transfer, ensuring proper flow, pressure, and containment.

How do I prevent leaks in pipe and hose connections?

To prevent leaks in pipe and hose connections, ensure proper installation and maintenance. Use the correct size and type of fittings for the application, and make sure all connections are clean and free of debris before assembly. Apply thread sealant or PTFE tape to threaded connections to create a tight seal. For hose connections, use appropriate clamps and ensure they are tightened sufficiently. Regularly inspect connections for signs of wear, corrosion, or damage, and replace worn components promptly. Avoid over-tightening, which can strip threads or damage seals, and under-tightening, which can lead to seepage.

What is the best way to cut and install tubing?

To cut tubing, use a specialized tubing cutter for clean, burr-free edges, or a fine-tooth hacksaw with a miter box for precision. Deburr the inside and outside of the cut end to ensure smooth flow and a proper seal. When installing, ensure the tubing is fully inserted into fittings until it bottoms out. For compression fittings, tighten the nut until snug, then an additional one-quarter to one-half turn, depending on the material and fitting type. For push-to-connect fittings, simply push the tube firmly into the fitting until it clicks into place, ensuring it's fully seated for a leak-proof connection.

How do I select the correct hose for high-pressure applications?

Selecting the correct hose for high-pressure applications is crucial for safety and efficiency. First, determine the maximum working pressure the hose will experience; this is the most critical factor. The hose's rated working pressure must always exceed this. Next, consider the fluid being conveyed and its temperature, as this impacts the hose's material compatibility. Ensure the hose material can withstand the fluid's chemical properties without degradation. The hose's inner diameter (ID) should match the required flow rate to prevent pressure drops or excessive velocity. Finally, evaluate the application's environmental conditions, such as abrasion, temperature extremes, and chemical exposure, to choose a hose with suitable outer protection and reinforcement.

What are the standard sizes for pipes and fittings?

Standard pipe and fitting sizes are primarily defined by two common systems: Nominal Pipe Size (NPS) and Diameter Nominal (DN). NPS is a North American standard, while DN is a European and international standard. These systems refer to the pipe's approximate inside diameter, not its actual outside diameter, which can vary based on the pipe schedule (wall thickness). Common NPS sizes include 1/2-inch, 3/4-inch, 1-inch, 2-inch, 4-inch, and so on. Corresponding DN sizes are in millimeters, such as DN15, DN20, DN25, etc. Fittings are designed to match these standard pipe sizes to ensure proper connection and flow.

How do I repair a damaged hose or pipe?

To repair a damaged hose or pipe, first identify the type of damage. For small punctures in rubber or plastic hoses, a hose repair kit with a patch and sealant can be effective. Cut out the damaged section for more severe damage and insert a hose mender with clamps. For rigid pipes, a temporary fix might involve epoxy putty or repair clamps, but a permanent solution usually requires cutting out the damaged section and replacing it with new pipe using appropriate fittings and adhesive or soldering, depending on the material. Always ensure the water supply is turned off before starting repairs.