- Home

- Material Handling

- Storage Workspace

- Drums Pails Ibc Totes Tanks

- Drums Drum Handling Equipment

.....Read More

Closed Head Transport Drums

Covers for Closed Head Drums

Drum Bungs, Capseals & Locks

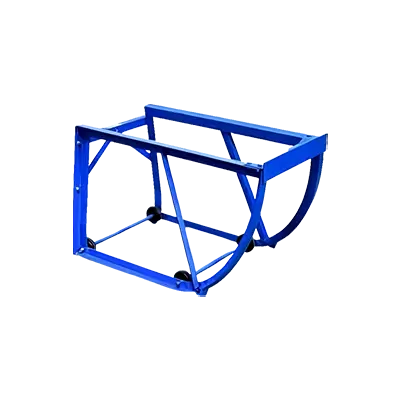

Drum Cradles & Upenders

Drum Crushers & Compactors

Drum Deheaders & Capseal Tools

Drum Dispensing & Palletizing Trucks

Drum Dollies

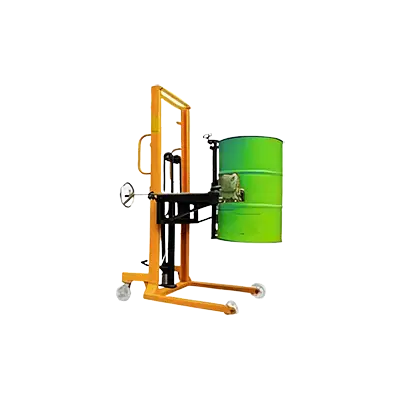

Drum Dumpers & Stackers

Drum Faucets

Drum Funnels & Accessories

Drum Hand Trucks

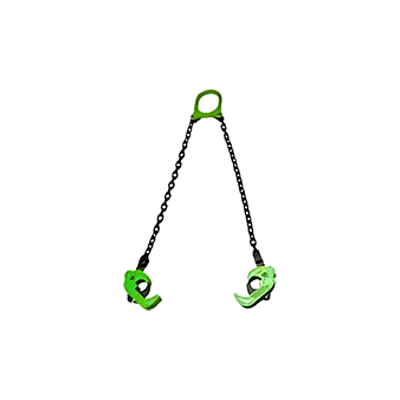

Drum Lifting Hooks & Slings

Drum Liners

Drum Replacement Gaskets & Leak Repair

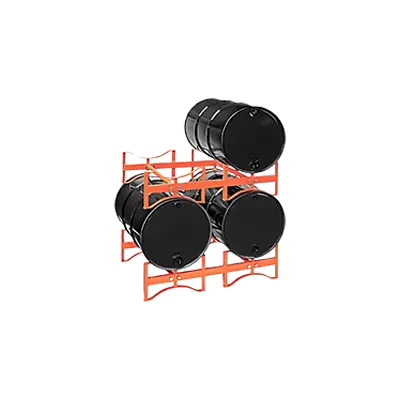

Drum Storage Racks

Drum Vents & Desiccants

Lids, Covers & Rings for Open Head Drums

Lids for Overpack & Salvage Drums

Open Head Transport Drums

Replacement Parts for Drum Handling Equipment

Salvage & Overpack Drums

Frequently Asked Questions

What are the different types of drums used for storing and transporting materials?

How do I choose the right drum handling equipment for my needs?

What are the benefits of using drum liners?

How do drum funnels and faucets work for controlled filling and dispensing?

What is the purpose of drum vents and desiccants?

How do I safely remove the top of a closed-head drum?

What tools are needed to attach or remove capseals on bungholes?