Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Material Handling

- Storage Workspace

- Drums Pails Ibc Totes Tanks

.....Read More

Frequently Asked Questions

What are the different types of drums and their uses?

Drums are diverse percussion instruments used across various musical genres and cultural contexts. Here are some common types and their uses:

1. **Snare Drum**: Known for its sharp staccato sound, the snare drum is central to marching bands, orchestras, and drum kits. It provides rhythm and accents in rock, pop, and jazz music.

2. **Bass Drum**: This large drum produces deep, low tones and is a staple in drum kits, orchestras, and marching bands. It maintains the beat and adds depth to musical compositions.

3. **Tom-Toms**: Used in drum kits, tom-toms come in various sizes and are played to add fills and rhythmic variations in rock, jazz, and pop music.

4. **Floor Tom**: A larger tom-tom placed on the floor, it provides deeper tones and is used for dramatic fills and accents in drum solos.

5. **Bongos**: These small, paired drums are played with the hands and are essential in Latin music, providing rhythmic patterns and lively beats.

6. **Congas**: Taller than bongos, congas are played with the hands and are integral to Afro-Cuban music, salsa, and Latin jazz, offering rich, resonant sounds.

7. **Djembe**: Originating from West Africa, the djembe is played with bare hands and is used in traditional African music, drum circles, and world music for its versatile tones.

8. **Tabla**: A pair of drums from India, the tabla is used in classical Indian music, providing intricate rhythms and complex patterns.

9. **Timpani**: Also known as kettle drums, timpani are used in orchestras and concert bands, offering powerful, resonant tones that enhance dramatic musical passages.

10. **Electronic Drums**: These mimic acoustic drum sounds and are used in various music genres for their versatility and ability to produce a wide range of sounds.

Each drum type contributes unique sounds and rhythms, enriching musical compositions and performances across cultures and genres.

How do I choose the right IBC tote for my needs?

To choose the right IBC tote, consider the following factors:

1. **Material Compatibility**: Ensure the tote material is compatible with the contents. Common materials include high-density polyethylene (HDPE) for chemicals and food-grade products, and stainless steel for corrosive or high-purity substances.

2. **Capacity**: Determine the volume you need. Standard IBC totes range from 275 to 330 gallons, but smaller or larger sizes may be available.

3. **Regulatory Compliance**: Check for compliance with relevant regulations, such as UN/DOT for hazardous materials or FDA for food products.

4. **Design Type**: Choose between rigid, flexible, or collapsible IBCs based on storage and transport needs. Rigid IBCs offer durability, flexible IBCs save space when empty, and collapsible IBCs provide easy storage.

5. **Temperature Requirements**: Consider if the contents require temperature control. Some IBCs offer insulation or heating options.

6. **Reusability and Lifecycle**: Decide if you need a single-use or reusable tote. Reusable IBCs are cost-effective for long-term use, while single-use may be suitable for one-time shipments.

7. **Handling and Transport**: Ensure the IBC is compatible with your handling equipment, such as forklifts or pallet jacks, and consider the ease of stacking and transport.

8. **Discharge and Filling**: Evaluate the valve and opening types for ease of filling and discharging contents. Common options include ball valves and butterfly valves.

9. **Cost**: Balance your budget with the features you need. While initial costs may be higher for certain types, long-term savings from reusability or reduced product loss can be significant.

10. **Supplier Reputation**: Choose a reputable supplier with good customer service and support to ensure quality and reliability.

By considering these factors, you can select an IBC tote that meets your specific requirements efficiently.

What equipment is needed for safe drum handling?

For safe drum handling, the following equipment is essential:

1. **Drum Dollies**: These are wheeled platforms designed to transport drums easily. They reduce manual lifting and allow for smooth movement across flat surfaces.

2. **Drum Trucks**: These are specialized hand trucks with a curved back and straps to secure the drum, allowing for easy tilting and rolling.

3. **Drum Lifts and Hoists**: These devices are used to lift drums vertically. They can be manual or powered and are essential for stacking or loading drums onto shelves or vehicles.

4. **Drum Grabs and Tongs**: These are attachments for forklifts or cranes that grip the drum securely, allowing for safe lifting and moving without manual handling.

5. **Drum Rotators and Tilters**: These are used to rotate or tilt drums for mixing contents or emptying them safely. They can be manual or powered.

6. **Spill Containment Pallets**: These are platforms with built-in sumps to catch leaks or spills, preventing environmental contamination and ensuring workplace safety.

7. **Drum Pumps**: These are used to safely transfer liquids from drums, minimizing the risk of spills and exposure to hazardous substances.

8. **Personal Protective Equipment (PPE)**: Depending on the drum contents, PPE such as gloves, goggles, and aprons may be necessary to protect against chemical exposure.

9. **Drum Cradles**: These are used to hold drums securely in place during transport or storage, preventing rolling or tipping.

10. **Forklift Attachments**: Specialized attachments for forklifts can handle drums safely, including drum clamps and rotators.

11. **Drum Wrenches**: These are used to open and close drum bungs and lids safely, reducing the risk of spills or exposure.

Using the appropriate equipment ensures the safe handling of drums, reducing the risk of injury and environmental hazards.

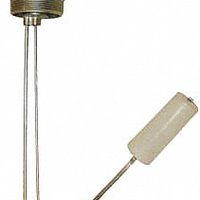

How do liquid level gauges work in sealed containers?

Liquid level gauges in sealed containers work by using various principles to measure the level of liquid without opening the container. Common methods include:

1. **Float-Type Gauges**: These use a float that rises and falls with the liquid level. The float is connected to a mechanical indicator or a magnet that moves along a calibrated scale outside the container.

2. **Hydrostatic Pressure Gauges**: These measure the pressure exerted by the liquid column. The pressure is proportional to the liquid level, and sensors convert this pressure into a readable level indication.

3. **Capacitance Gauges**: These use the principle of capacitance change. A probe inside the container acts as one plate of a capacitor, and the liquid acts as the dielectric. As the liquid level changes, the capacitance changes, which is measured and converted into a level reading.

4. **Ultrasonic Gauges**: These emit ultrasonic waves from a transducer at the top of the container. The waves reflect off the liquid surface and return to the sensor. The time taken for the waves to return is used to calculate the liquid level.

5. **Radar Gauges**: Similar to ultrasonic gauges, radar gauges use microwave radar signals. They are highly accurate and unaffected by temperature, pressure, or vapor.

6. **Conductivity Probes**: These use the electrical conductivity of the liquid. Probes at different levels detect the presence or absence of liquid, providing a level indication.

7. **Magnetostrictive Gauges**: These use a magnetic float and a waveguide. A current pulse creates a magnetic field, and the interaction with the float's magnetic field generates a torsional wave. The time taken for the wave to return is used to determine the liquid level.

Each method has its advantages and is chosen based on factors like the type of liquid, container material, required accuracy, and environmental conditions.

What are the benefits of using heaters and insulators for liquid storage?

Heaters and insulators play crucial roles in the efficient storage of liquids, offering several benefits:

1. **Temperature Control**: Heaters maintain the desired temperature of stored liquids, preventing freezing or excessive cooling, which is essential for substances like oils, chemicals, or beverages that require specific temperature ranges for stability and usability.

2. **Energy Efficiency**: Insulators minimize heat loss, reducing the energy required to maintain the temperature. This leads to cost savings and a smaller environmental footprint by decreasing the need for continuous heating.

3. **Quality Preservation**: Maintaining consistent temperatures helps preserve the quality and integrity of sensitive liquids, such as food products, pharmaceuticals, and chemicals, by preventing degradation or spoilage.

4. **Operational Continuity**: In industrial settings, heaters ensure that processes relying on liquid flow are not disrupted by temperature-induced viscosity changes, which can impede pumping and processing.

5. **Safety**: Proper temperature management reduces the risk of accidents related to freezing or overheating, such as pipe bursts or chemical reactions, enhancing overall safety in storage facilities.

6. **Extended Storage Life**: By preventing temperature fluctuations, heaters and insulators extend the shelf life of stored liquids, reducing waste and ensuring availability when needed.

7. **Versatility**: Heaters and insulators can be adapted to various storage conditions and liquid types, providing flexibility in managing different storage requirements.

8. **Environmental Protection**: Insulation reduces the need for additional heating, lowering emissions and contributing to environmental conservation efforts.

In summary, the use of heaters and insulators in liquid storage ensures temperature stability, energy efficiency, quality preservation, operational continuity, safety, extended storage life, versatility, and environmental protection.

How do mixers and mixing enclosures improve material consistency?

Mixers and mixing enclosures enhance material consistency by ensuring uniform distribution of components within a mixture. They achieve this through several mechanisms:

1. **Homogenization**: Mixers apply mechanical forces to blend materials, breaking down agglomerates and ensuring even distribution. This process reduces variability in the final product, leading to consistent quality.

2. **Controlled Environment**: Mixing enclosures provide a controlled environment that can regulate temperature, humidity, and contamination levels. This control is crucial for materials sensitive to environmental changes, ensuring that the mixing process does not introduce inconsistencies.

3. **Shear and Flow Dynamics**: Different types of mixers, such as paddle, ribbon, or planetary mixers, use specific shear and flow dynamics to achieve thorough mixing. These dynamics ensure that all parts of the material are exposed to the same conditions, promoting uniformity.

4. **Time and Speed Regulation**: Mixers allow precise control over mixing time and speed, which are critical parameters for achieving desired consistency. Adjusting these parameters helps in optimizing the mixing process for different materials.

5. **Scalability**: Mixing enclosures can be designed to handle various batch sizes, ensuring that the consistency achieved in small-scale mixing is replicable in larger batches. This scalability is essential for maintaining quality across production volumes.

6. **Reduction of Segregation**: Enclosures minimize the risk of segregation by containing the materials within a confined space, preventing separation due to external factors like vibration or air currents.

7. **Enhanced Mixing Techniques**: Advanced mixers incorporate techniques like vacuum mixing or the use of baffles to improve the mixing process, ensuring that even challenging materials achieve the desired consistency.

By integrating these elements, mixers and mixing enclosures play a crucial role in achieving and maintaining material consistency, which is vital for product quality and performance.

What are the best practices for storing and transporting liquids in tanks and totes?

Best practices for storing and transporting liquids in tanks and totes include:

1. **Material Compatibility**: Ensure the tank or tote material is compatible with the liquid to prevent reactions or degradation. Use stainless steel, polyethylene, or other suitable materials based on the liquid's properties.

2. **Proper Labeling**: Clearly label tanks and totes with the contents, hazard warnings, and handling instructions to ensure safety and compliance with regulations.

3. **Temperature Control**: Maintain appropriate temperature conditions to prevent freezing, overheating, or chemical reactions. Use insulation or heating systems if necessary.

4. **Secure Sealing**: Ensure all lids, caps, and valves are tightly sealed to prevent leaks, spills, and contamination during storage and transport.

5. **Regular Inspection**: Conduct routine inspections for signs of wear, corrosion, or damage. Address any issues immediately to prevent leaks or failures.

6. **Secondary Containment**: Use secondary containment systems like bunds or spill pallets to catch leaks or spills, protecting the environment and personnel.

7. **Ventilation**: Ensure proper ventilation to prevent pressure build-up and allow for safe release of vapors, especially for volatile or hazardous liquids.

8. **Compliance with Regulations**: Adhere to local, national, and international regulations regarding the storage and transport of liquids, including hazardous materials guidelines.

9. **Training and Safety Protocols**: Train personnel in safe handling, emergency response, and proper use of personal protective equipment (PPE).

10. **Transport Security**: Secure tanks and totes during transport to prevent movement or tipping. Use appropriate strapping and bracing methods.

11. **Documentation**: Maintain accurate records of contents, inspections, and maintenance activities for traceability and compliance.

12. **Emergency Preparedness**: Have spill response kits and emergency plans in place to quickly address any incidents.