Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Material Handling

- Lifting Pulling Positioning

- Lifting Rigging Hardware

.....Read More

Frequently Asked Questions

What are the different types of lifting and rigging hardware?

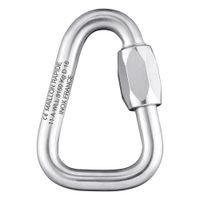

Lifting and rigging hardware are essential components in material handling, ensuring safe and efficient movement of loads. Key types include:

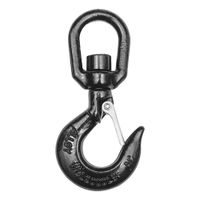

1. **Hooks**: Used to connect lifting slings to loads, available in various designs like eye hooks, clevis hooks, and swivel hooks, each suited for specific applications.

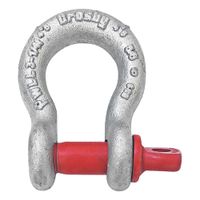

2. **Shackles**: U-shaped devices with a pin or bolt across the opening, used to connect lifting slings, chains, or ropes. Types include anchor (bow) shackles and chain (D) shackles.

3. **Slings**: Flexible lifting devices made from materials like wire rope, chain, or synthetic fibers. Types include wire rope slings, chain slings, and synthetic web or round slings.

4. **Eyebolts and Eye Nuts**: Threaded fasteners with a looped end, used for attaching ropes or cables to a load. Variants include shoulder eyebolts and plain eyebolts.

5. **Turnbuckles**: Used to adjust tension in ropes, cables, or tie rods, consisting of a metal frame with threaded ends. Types include jaw-jaw, eye-eye, and hook-eye configurations.

6. **Blocks and Pulleys**: Used to change the direction of a rope or cable, reducing the force needed to lift a load. They consist of a wheel with a groove for the rope and are used in conjunction with slings and hooks.

7. **Hoists**: Devices used to lift or lower loads, available in manual, electric, or pneumatic versions. Types include chain hoists, wire rope hoists, and lever hoists.

8. **Load Binders**: Used to secure loads on transport vehicles, typically used with chains. Types include ratchet binders and lever binders.

9. **Swivels**: Allow rotation of the load without twisting the lifting medium, used in conjunction with hooks or slings.

10. **Snatch Blocks**: A type of pulley block that can open to accept a loop of rope, used to redirect a rope or increase lifting capacity.

These components are crucial for ensuring safety and efficiency in lifting operations.

How do you choose the right lifting hook for a specific application?

To choose the right lifting hook for a specific application, consider the following factors:

1. **Load Capacity**: Determine the maximum weight the hook will need to lift. Choose a hook with a working load limit (WLL) that exceeds this weight to ensure safety.

2. **Material**: Select a hook made from durable materials like alloy steel, which offers high strength and resistance to wear and tear.

3. **Type of Hook**: Choose the appropriate type based on the application:

- **Eye Hooks**: For permanent connections.

- **Clevis Hooks**: For easy attachment and detachment.

- **Swivel Hooks**: For applications requiring rotation to prevent twisting of the load.

- **Grab Hooks**: For shortening or adjusting chain lengths.

4. **Design and Safety Features**: Look for hooks with safety latches to prevent accidental detachment of the load. Consider self-locking hooks for added security.

5. **Environment**: Consider environmental factors such as temperature, humidity, and exposure to chemicals. Choose hooks with coatings or materials that resist corrosion and withstand environmental conditions.

6. **Compatibility**: Ensure the hook is compatible with the lifting equipment and accessories, such as chains, slings, or ropes.

7. **Regulations and Standards**: Ensure the hook complies with relevant industry standards and regulations, such as those from OSHA or ASME, to ensure safety and reliability.

8. **Frequency of Use**: For frequent use, select a hook designed for durability and long service life.

9. **Inspection and Maintenance**: Choose a hook that is easy to inspect and maintain to ensure ongoing safety and performance.

By considering these factors, you can select a lifting hook that is safe, efficient, and suitable for your specific lifting application.

What are the safety guidelines for using shackles in rigging?

1. **Selection**: Choose the right type and size of shackle for the load. Ensure the Working Load Limit (WLL) is appropriate for the task.

2. **Inspection**: Before use, inspect shackles for wear, deformation, cracks, and corrosion. Check the pin for straightness and ensure threads are not damaged.

3. **Pin Security**: Use the correct pin type (screw pin, bolt-type, or round pin) for the application. Ensure the pin is fully engaged and secured. For screw pin shackles, hand-tighten and then back off slightly to prevent binding.

4. **Load Alignment**: Ensure the load is applied in-line with the shackle body. Avoid side loading, which can reduce the shackle's capacity and cause failure.

5. **Avoid Overloading**: Never exceed the shackle's WLL. Consider dynamic forces and shock loading, which can increase the effective load.

6. **Temperature and Environment**: Be aware of environmental factors. Extreme temperatures and corrosive environments can affect shackle performance.

7. **Avoid Modifications**: Do not modify shackles. Alterations can compromise their integrity and safety.

8. **Proper Storage**: Store shackles in a dry, clean area to prevent corrosion and damage.

9. **Use with Compatible Equipment**: Ensure shackles are compatible with other rigging equipment. Mismatched sizes or types can lead to unsafe conditions.

10. **Training**: Ensure personnel are trained in the proper use and inspection of shackles.

11. **Documentation**: Keep records of inspections and maintenance. Follow manufacturer guidelines and industry standards.

12. **Replacement**: Replace shackles that show signs of wear, damage, or have been overloaded.

13. **Avoid Shock Loading**: Gradually apply loads to avoid sudden forces that can exceed the shackle's capacity.

How do you properly install and use hoist rings?

To properly install and use hoist rings, follow these steps:

1. **Selection**: Choose the appropriate hoist ring based on load weight, type, and lifting angle. Ensure it meets the required safety standards and has a load capacity greater than the weight of the object being lifted.

2. **Inspection**: Before installation, inspect the hoist ring for any signs of wear, corrosion, or damage. Check that the swivel and pivot points move freely.

3. **Installation**:

- **Positioning**: Align the hoist ring with the load's center of gravity to ensure balanced lifting.

- **Mounting Surface**: Ensure the mounting surface is flat, clean, and capable of supporting the load.

- **Fastening**: Use the correct size and grade of bolts as specified by the manufacturer. Tighten bolts to the recommended torque using a calibrated torque wrench. Avoid using washers unless specified.

- **Orientation**: Install the hoist ring so it can swivel and pivot freely without obstruction.

4. **Pre-Lift Check**:

- Verify that the hoist ring is securely fastened and properly aligned.

- Ensure the load is evenly distributed and the hoist ring is not subjected to side loading.

5. **Lifting**:

- Use a slow and steady lift to avoid shock loading.

- Maintain a clear area around the load and ensure all personnel are at a safe distance.

- Continuously monitor the hoist ring and load for any signs of instability or unusual movement.

6. **Post-Use**:

- After use, inspect the hoist ring for any damage or wear.

- Store in a clean, dry place to prevent corrosion.

Regular maintenance and adherence to manufacturer guidelines are crucial for safe operation.

What is the purpose of pulley blocks and sheaves in lifting operations?

Pulley blocks and sheaves are essential components in lifting operations, primarily used to facilitate the movement and control of heavy loads. Their primary purpose is to change the direction of the applied force and to multiply the force exerted, making it easier to lift heavy objects with less effort.

Pulley blocks consist of one or more sheaves, which are the grooved wheels that guide the rope or cable. When a rope is threaded through the sheaves, it creates a mechanical advantage by distributing the weight of the load across multiple segments of the rope. This setup allows for a significant reduction in the amount of force needed to lift the load, effectively multiplying the input force. The more sheaves used in a block and tackle system, the greater the mechanical advantage, allowing for the lifting of heavier loads with the same amount of input force.

Additionally, pulley blocks and sheaves help in redirecting the force applied, enabling loads to be lifted vertically while the pulling force is applied horizontally. This flexibility is crucial in various industrial and construction settings where space and direction constraints exist.

Furthermore, these components contribute to safety and efficiency in lifting operations. By reducing the physical strain on workers and minimizing the risk of overloading equipment, pulley blocks and sheaves help prevent accidents and equipment failure. They also allow for more precise control over the movement of loads, enhancing the accuracy and reliability of lifting operations.

In summary, pulley blocks and sheaves are vital for improving the efficiency, safety, and effectiveness of lifting operations by providing mechanical advantage, changing force direction, and enabling precise load control.

How do swivels and turnbuckles function in rigging systems?

Swivels and turnbuckles are essential components in rigging systems, each serving distinct functions to ensure stability, adjustability, and safety.

Swivels are used to allow rotation without twisting the attached cables or ropes. They consist of two end fittings connected by a central pivot, enabling 360-degree rotation. This rotation capability is crucial in applications where the load or the rigging system may rotate, such as in cranes or hoisting operations. By preventing the cables from twisting, swivels reduce stress and wear on the rigging components, enhancing their longevity and reliability. They also help in maintaining the correct orientation of the load, which is vital for precise positioning and safety.

Turnbuckles, on the other hand, are used to adjust the tension or length of cables, ropes, or rods in rigging systems. They consist of a metal frame with two threaded end fittings, one with a left-hand thread and the other with a right-hand thread. By rotating the frame, the end fittings move closer together or further apart, effectively tightening or loosening the connected lines. This adjustability is crucial for ensuring the correct tension in guy wires, suspension cables, and other rigging applications. Proper tensioning helps in maintaining structural integrity, preventing sagging, and ensuring that loads are evenly distributed.

Together, swivels and turnbuckles enhance the functionality and safety of rigging systems. Swivels prevent twisting and allow for free movement, while turnbuckles provide precise tension adjustments. Their combined use ensures that rigging systems can handle dynamic loads and environmental conditions effectively, making them indispensable in construction, maritime, and industrial applications.

What are the best practices for maintaining and inspecting lifting and rigging equipment?

Best practices for maintaining and inspecting lifting and rigging equipment include:

1. **Regular Inspections**: Conduct pre-use inspections to check for wear, damage, or defects. Schedule periodic thorough inspections by qualified personnel to ensure compliance with safety standards.

2. **Documentation**: Maintain detailed records of inspections, maintenance, and repairs. This includes logging dates, findings, corrective actions, and the personnel involved.

3. **Training**: Ensure all personnel involved in lifting and rigging operations are properly trained in equipment use, inspection procedures, and safety protocols.

4. **Proper Storage**: Store equipment in a clean, dry environment to prevent damage from environmental factors. Use racks or designated areas to avoid tangling or crushing.

5. **Load Testing**: Perform load tests as required by regulations or manufacturer guidelines to verify the equipment's capacity and integrity.

6. **Lubrication and Cleaning**: Regularly clean and lubricate moving parts to prevent rust and ensure smooth operation. Use appropriate cleaning agents that do not degrade the equipment material.

7. **Replacement of Damaged Parts**: Immediately replace any damaged or worn components. Do not attempt to repair critical components unless specified by the manufacturer.

8. **Use of Manufacturer Guidelines**: Follow the manufacturer's instructions for maintenance, inspection, and operation. Use only approved parts and accessories.

9. **Safety Checks**: Implement safety checks before each use, including verifying load limits, checking for proper rigging, and ensuring all safety devices are functional.

10. **Risk Assessment**: Conduct risk assessments for lifting operations to identify potential hazards and implement control measures.

11. **Compliance with Standards**: Adhere to relevant industry standards and regulations, such as OSHA, ANSI, or ISO, to ensure safety and compliance.

12. **Communication**: Foster clear communication among team members to ensure everyone is aware of procedures, hazards, and responsibilities.