Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Material Handling

- Lifting Pulling Positioning

- Lifting Rigging Hardware

- Lifting Rigging Hooks

.....Read More

Frequently Asked Questions

What are the different types of lifting hooks?

There are several types of lifting hooks, each designed for specific applications and load requirements:

1. **Eye Hooks**: These hooks have a circular eye at the top for easy attachment to chains or ropes. They are versatile and commonly used in various lifting operations.

2. **Clevis Hooks**: Featuring a U-shaped attachment point secured with a pin, clevis hooks are ideal for quick connections and disconnections. They are often used in rigging and towing applications.

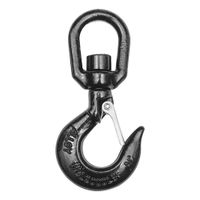

3. **Swivel Hooks**: Equipped with a swivel mechanism, these hooks can rotate 360 degrees, preventing twisting of the load. They are useful in applications where load rotation is necessary.

4. **Grab Hooks**: Designed with a narrow throat, grab hooks securely hold onto chains without slipping. They are typically used for shortening or adjusting chain lengths.

5. **Slip Hooks**: These hooks have a wider throat, allowing chains to slip through easily. They are often used in towing and load binding applications.

6. **Self-Locking Hooks**: Featuring a latch that automatically closes under load, self-locking hooks provide enhanced safety by preventing accidental detachment.

7. **Foundry Hooks**: With a wide throat and no latch, foundry hooks are used for lifting large, bulky items like molds and castings.

8. **Sorting Hooks**: These hooks have a long, narrow design, making them suitable for sorting and separating materials.

9. **Drum Hooks**: Specifically designed for lifting drums, these hooks have a shape that fits securely around the drum's rim.

10. **C-Hooks**: Shaped like the letter "C," these hooks are used for lifting coils of materials such as steel or wire.

11. **J-Hooks**: With a J-shaped design, these hooks are used for lifting and securing loads in various industrial applications.

Each type of hook is selected based on the specific requirements of the lifting task, including load type, weight, and safety considerations.

How do you determine the load capacity of a lifting hook?

To determine the load capacity of a lifting hook, follow these steps:

1. **Material Properties**: Identify the material of the hook, as different materials have varying strength characteristics. Obtain the tensile strength and yield strength from material specifications.

2. **Design Standards**: Refer to relevant standards such as ASME B30.10, DIN 15401, or ISO standards, which provide guidelines for hook design and load capacity.

3. **Hook Geometry**: Measure the critical dimensions of the hook, including the throat opening, hook depth, and cross-sectional area at the narrowest point. These dimensions are crucial for calculating stress distribution.

4. **Stress Analysis**: Perform a stress analysis using the hook's geometry and material properties. Calculate the maximum stress using the formula:

\[

\text{Stress} = \frac{\text{Load}}{\text{Cross-sectional Area}}

\]

Ensure that the calculated stress does not exceed the material's yield strength.

5. **Safety Factor**: Apply an appropriate safety factor, typically ranging from 4 to 5, to account for dynamic loads, wear, and potential defects. The safety factor reduces the maximum allowable load to ensure safe operation.

6. **Load Testing**: Conduct a load test by applying a load to the hook, usually 1.25 to 1.5 times the rated capacity, to verify its performance under controlled conditions.

7. **Inspection and Maintenance**: Regularly inspect the hook for signs of wear, deformation, or damage. Ensure that the hook is maintained according to manufacturer guidelines to preserve its load capacity.

8. **Manufacturer Specifications**: Consult the manufacturer's documentation for specific load ratings and recommendations, as they may have conducted extensive testing and analysis.

By following these steps, you can accurately determine the load capacity of a lifting hook, ensuring safe and efficient lifting operations.

What safety precautions should be taken when using lifting hooks?

1. **Inspection**: Regularly inspect lifting hooks for wear, deformation, cracks, or corrosion. Replace any damaged hooks immediately.

2. **Load Limits**: Adhere to the manufacturer's specified load limits. Never exceed the rated capacity of the hook.

3. **Proper Attachment**: Ensure the hook is properly attached to the load and lifting device. The load should be centered in the bowl of the hook to prevent side loading.

4. **Secure Latch**: Use hooks with safety latches to prevent accidental detachment of the load. Ensure the latch is functioning correctly.

5. **Avoid Shock Loading**: Lift loads smoothly to avoid shock loading, which can cause sudden stress and potential failure of the hook.

6. **Correct Angle**: Maintain the correct angle when lifting. Avoid side loading or back hooking, which can lead to hook failure.

7. **Training**: Ensure all personnel involved in lifting operations are properly trained in the use of lifting hooks and understand safety protocols.

8. **Clear Area**: Keep the area around the lifting operation clear of unnecessary personnel and obstacles to prevent accidents.

9. **Communication**: Use clear signals or communication devices to coordinate lifting operations among team members.

10. **Environmental Conditions**: Consider environmental factors such as wind, rain, or ice that may affect the lifting operation and take appropriate precautions.

11. **Storage**: Store hooks properly when not in use to prevent damage and ensure they remain in good condition.

12. **Documentation**: Maintain records of inspections, maintenance, and any incidents involving lifting hooks for accountability and future reference.

How do you inspect lifting hooks for wear and damage?

To inspect lifting hooks for wear and damage, follow these steps:

1. **Visual Inspection**: Examine the hook for any visible signs of wear, deformation, cracks, or corrosion. Pay special attention to the throat opening, which should not be stretched beyond manufacturer specifications.

2. **Check for Deformation**: Measure the hook's throat opening and compare it to the original dimensions. Any increase in size indicates deformation. Also, inspect for twisting or bending of the hook body.

3. **Surface Condition**: Look for nicks, gouges, or sharp edges that could compromise the hook's integrity. Smooth out minor surface imperfections if allowed by the manufacturer.

4. **Inspect the Latch**: Ensure the safety latch is functioning correctly, closing fully and not showing signs of wear or damage. The latch should move freely and spring back into place.

5. **Check for Cracks**: Use a magnifying glass or dye penetrant test to detect fine cracks, especially around high-stress areas like the hook's neck and eye.

6. **Corrosion and Rust**: Identify any rust or corrosion, which can weaken the hook. Clean and treat minor rust, but replace the hook if corrosion is extensive.

7. **Load Test**: If required, perform a load test to ensure the hook can handle its rated capacity without deformation or failure.

8. **Documentation**: Record all findings, including measurements and any maintenance performed. Keep a log for future reference and compliance with safety regulations.

9. **Manufacturer Guidelines**: Always refer to the manufacturer's guidelines for specific inspection criteria and tolerances.

10. **Frequency**: Conduct inspections regularly, with frequency depending on usage, environment, and regulatory requirements.

Replace the hook if any defects are found that compromise safety or if it fails to meet inspection criteria.

What are the common materials used for manufacturing lifting hooks?

Common materials used for manufacturing lifting hooks include:

1. **Carbon Steel**: Known for its strength and durability, carbon steel is a popular choice for lifting hooks. It offers a good balance between cost and performance, making it suitable for various industrial applications.

2. **Alloy Steel**: This material is an enhanced version of carbon steel, with added elements like chromium, nickel, and molybdenum to improve its mechanical properties. Alloy steel lifting hooks are known for their high strength, toughness, and resistance to wear and fatigue.

3. **Stainless Steel**: Stainless steel lifting hooks are used in environments where corrosion resistance is crucial, such as in marine or chemical industries. The presence of chromium in stainless steel provides excellent resistance to rust and corrosion.

4. **Forged Steel**: Forged steel hooks are manufactured through a process that involves shaping the metal using compressive forces. This results in a product with superior strength and structural integrity, making it ideal for heavy-duty lifting applications.

5. **Cast Steel**: Cast steel hooks are made by pouring molten steel into molds. They are typically used for applications where precise shapes and sizes are required. While not as strong as forged steel, cast steel can be more cost-effective for certain uses.

6. **High-Strength Low-Alloy (HSLA) Steel**: HSLA steel is designed to provide better mechanical properties and greater resistance to atmospheric corrosion than conventional carbon steel. It is often used in lifting hooks for its enhanced strength-to-weight ratio.

7. **Ductile Iron**: Although less common, ductile iron can be used for lifting hooks in specific applications. It offers good strength and ductility, making it suitable for certain lifting tasks.

These materials are selected based on factors such as load capacity, environmental conditions, and specific application requirements.

How do you properly attach a lifting hook to a load?

To properly attach a lifting hook to a load, follow these steps:

1. **Inspect Equipment**: Ensure the lifting hook, sling, and any other lifting equipment are in good condition, free from defects, and rated for the load's weight.

2. **Determine Load Weight and Center of Gravity**: Know the load's weight and identify its center of gravity to ensure stability during lifting.

3. **Select Appropriate Sling**: Choose a sling type (chain, wire rope, synthetic) suitable for the load's weight, shape, and material.

4. **Position the Hook**: Align the hook directly above the load's center of gravity to prevent swinging or tipping.

5. **Attach Sling to Load**: Securely attach the sling to the load using appropriate methods (e.g., choker, basket, or vertical hitch) ensuring even weight distribution.

6. **Engage the Hook**: Place the sling's eye or loop into the hook's saddle, ensuring the hook's latch is closed and locked to prevent accidental release.

7. **Check Sling Angle**: Maintain a sling angle of 60 degrees or more to reduce stress on the sling and ensure safe lifting.

8. **Conduct a Pre-Lift Check**: Verify all connections are secure, the load is balanced, and the lifting path is clear of obstructions.

9. **Lift Slowly and Steadily**: Begin lifting slowly to check for stability and balance, making adjustments if necessary.

10. **Monitor During Lift**: Continuously observe the load for any signs of shifting or instability, and stop immediately if any issues arise.

11. **Lower Carefully**: Once the load is moved, lower it slowly to its destination, ensuring it is stable before detaching the hook.

12. **Detach and Inspect**: After the load is safely placed, detach the hook and inspect all equipment for any damage before storing.

What are the regulations and standards for lifting hooks?

Regulations and standards for lifting hooks are primarily governed by organizations such as the Occupational Safety and Health Administration (OSHA) in the United States, the American Society of Mechanical Engineers (ASME), and the International Organization for Standardization (ISO).

1. **OSHA Standards**: OSHA's regulations for lifting hooks fall under the general industry standards (29 CFR 1910) and construction standards (29 CFR 1926). These regulations require that lifting hooks be inspected regularly for deformation, cracks, and wear. Hooks must have safety latches unless the application makes the use of a latch impractical.

2. **ASME B30.10**: This standard provides guidelines for the inspection, maintenance, and operation of hooks. It categorizes hooks into different service classes based on their usage and outlines specific inspection intervals and criteria for removal from service. Hooks must be marked with the manufacturer's identification and rated load.

3. **ISO 7597**: This international standard specifies the requirements for lifting hooks, including their design, testing, and marking. It ensures that hooks are manufactured to withstand specific loads and stresses, and mandates regular inspections to ensure safety.

4. **Inspection and Maintenance**: Regular inspection is crucial. Hooks should be checked for signs of wear, corrosion, and deformation. Any hook showing a 10% reduction in the original dimension or any visible cracks should be removed from service.

5. **Load Testing**: Hooks must be load-tested to ensure they can handle the specified weight. This is often part of the initial certification process and may be required periodically depending on usage.

6. **Marking and Identification**: Hooks must be clearly marked with the rated load, manufacturer’s identification, and any other relevant information to ensure proper use and traceability.

Compliance with these standards ensures the safety and reliability of lifting operations.