- Home

- Material Handling

- Lifting Pulling Positioning

.....Read More

Below-the-Hook Lifting Devices

Box Dumpers

Cargo Lifting Nets

Chains

Cranes & Festoon Cable Systems

Drywall Lifts

Hoists & Trolleys

Lifting Magnets

Lifting & Rigging Hardware

Lifting Slings

Lift Tables, Turntables & Pallet Positioners

Manual Lifting Straps

Push-Pull Jacks

Rope & Twine

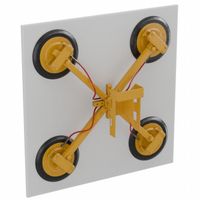

Suction Lifters

Winches

Wire Rope & Fittings

Frequently Asked Questions

What are the different types of hoists and their uses?

How do you properly secure a load with lifting slings?

What safety precautions should be taken when using cranes?

How do you choose the right winch for a specific application?

What are the benefits of using lift tables and turntables in material handling?

How do festoon cable systems work with cranes and hoists?

What is the difference between wire rope and synthetic rope?

How do you maintain and inspect lifting and rigging hardware?

What are the best practices for using drywall lifts?

How do you calculate the load capacity for chains and slings?