Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Material Handling

- Lifting Pulling Positioning

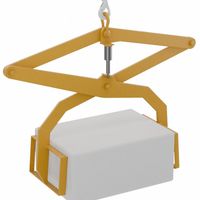

- Below The Hook Lifting Devices

.....Read More

Frequently Asked Questions

What are below-the-hook lifting devices?

Below-the-hook lifting devices are tools or equipment used to attach loads to cranes or other lifting machinery. These devices are essential for safely and efficiently handling materials in various industrial settings. They are positioned between the load and the lifting hook of the crane, hence the name "below-the-hook."

These devices come in various forms, each designed for specific types of loads and lifting requirements. Common types include:

1. **Lifting Beams and Spreaders**: These are horizontal beams that distribute the load evenly, reducing stress on the load and the lifting equipment. Spreaders are used to maintain the load's balance by keeping lifting slings apart.

2. **C-Hooks**: Designed for lifting coils of materials like steel or wire, C-hooks support the load from the inside of the coil.

3. **Grabs and Clamps**: These devices mechanically grip the load, often used for lifting irregularly shaped or heavy items like pipes, drums, or blocks.

4. **Magnets**: Used for lifting ferrous materials, magnetic lifters can be either permanent or electromagnets, providing a secure grip without the need for slings or chains.

5. **Vacuum Lifters**: These use suction to lift non-porous materials such as glass, metal sheets, or stone slabs, offering a non-invasive method of handling delicate items.

6. **Slings**: Made from materials like wire rope, chain, or synthetic fibers, slings are versatile and can be used in various configurations to secure loads.

Safety is paramount when using below-the-hook lifting devices. They must be regularly inspected and maintained to ensure they are in good working condition. Proper training for operators is also crucial to prevent accidents and ensure efficient load handling.

How do below-the-hook lifting devices attach to cranes or hoists?

Below-the-hook lifting devices attach to cranes or hoists through various methods, depending on the design and purpose of the device. These devices are engineered to connect securely to the crane or hoist and safely handle the load. Here are some common attachment methods:

1. **Hooks**: Many below-the-hook devices use hooks to attach to the crane or hoist. The hook on the lifting device engages with the crane's hook, providing a secure connection. Safety latches are often used to prevent accidental disengagement.

2. **Shackles**: Shackles are U-shaped devices with a pin or bolt across the opening. They are used to connect lifting devices to the crane's hook or other rigging equipment. Shackles provide a strong and secure connection.

3. **Lifting Eyes or Lugs**: Some lifting devices have built-in lifting eyes or lugs, which are holes or protrusions designed for attachment. These can be connected to the crane or hoist using shackles, hooks, or other rigging hardware.

4. **Slings**: Slings made of wire rope, chain, or synthetic materials can be used to attach lifting devices to cranes. The sling is looped through the lifting device and connected to the crane's hook or other rigging points.

5. **Clamps**: Certain lifting devices use clamps to attach to the load and the crane. These clamps grip the load securely and are connected to the crane via hooks or shackles.

6. **Magnets or Vacuum Lifters**: For specific applications, magnetic or vacuum lifters can be used. These devices attach to the load using magnetic force or suction and are connected to the crane through hooks or other rigging.

Each method ensures a secure connection, allowing the lifting device to safely handle and transport loads. Proper selection and use of these attachment methods are crucial for safe lifting operations.

What safety standards apply to below-the-hook lifting devices?

Below-the-hook lifting devices are subject to several safety standards to ensure safe operation and prevent accidents. Key standards include:

1. **OSHA Regulations (29 CFR 1910.184)**: The Occupational Safety and Health Administration (OSHA) provides regulations for the safe use of slings, which are often used in conjunction with below-the-hook lifting devices. These regulations cover inspection, maintenance, and operation requirements.

2. **ASME B30.20**: The American Society of Mechanical Engineers (ASME) B30.20 standard specifically addresses below-the-hook lifting devices. It includes guidelines for design, construction, installation, inspection, testing, maintenance, and operation. It also categorizes devices into structural and mechanical lifting devices, vacuum lifting devices, and magnet lifting devices, each with specific requirements.

3. **ASME BTH-1**: This standard provides design criteria for below-the-hook lifting devices. It covers structural and mechanical design, including load rating, stress analysis, and material selection to ensure devices can safely handle specified loads.

4. **ANSI/ASME B30.9**: This standard pertains to slings, which are often used with below-the-hook devices. It includes specifications for different types of slings, their construction, and safe usage practices.

5. **Inspection and Testing**: Regular inspection and testing are crucial. Devices must be inspected before use and periodically, with a focus on wear, deformation, and other potential issues. Load testing is often required to verify the device's capacity.

6. **Training and Competency**: Operators must be trained and competent in using below-the-hook lifting devices, understanding load limits, and recognizing potential hazards.

These standards collectively ensure that below-the-hook lifting devices are used safely and effectively, minimizing risks to personnel and equipment.

How do you choose the right below-the-hook lifting device for a specific load?

To choose the right below-the-hook lifting device for a specific load, follow these steps:

1. **Load Characteristics**: Determine the weight, shape, size, and material of the load. Consider any special handling requirements, such as fragility or surface sensitivity.

2. **Lifting Environment**: Assess the environment where the lifting will occur. Consider factors like temperature, humidity, and potential exposure to chemicals or corrosive substances.

3. **Lifting Method**: Decide on the lifting method based on the load's characteristics. Options include slings, spreader beams, lifting beams, magnets, vacuum lifters, and clamps.

4. **Capacity and Safety**: Ensure the device's rated capacity exceeds the load's weight. Factor in safety margins and comply with relevant standards and regulations.

5. **Load Stability**: Choose a device that maintains load stability during lifting. Consider the load's center of gravity and ensure even weight distribution.

6. **Attachment Points**: Identify suitable attachment points on the load. Ensure the device can securely attach without damaging the load.

7. **Ease of Use**: Consider the device's ease of use, including setup, operation, and maintenance. Ensure it is user-friendly and requires minimal training.

8. **Compatibility**: Ensure compatibility with existing lifting equipment, such as cranes or hoists. Check for any required adapters or modifications.

9. **Regulatory Compliance**: Verify compliance with industry standards and regulations, such as OSHA or ASME guidelines.

10. **Supplier Reputation**: Choose a reputable supplier with a track record of quality and reliability. Consider after-sales support and warranty options.

11. **Cost**: Evaluate the cost-effectiveness of the device, balancing initial investment with long-term benefits and maintenance costs.

By systematically evaluating these factors, you can select the most appropriate below-the-hook lifting device for your specific load and operational needs.

What maintenance is required for below-the-hook lifting devices?

Below-the-hook lifting devices require regular maintenance to ensure safety and efficiency. Key maintenance tasks include:

1. **Inspection**: Conduct daily visual inspections for wear, deformation, cracks, or corrosion. Check for loose or missing parts, and ensure all safety labels are legible.

2. **Lubrication**: Regularly lubricate moving parts such as hinges, pins, and bearings to prevent wear and ensure smooth operation.

3. **Testing**: Perform load tests periodically to verify the device's lifting capacity and structural integrity. Follow manufacturer guidelines for frequency and procedures.

4. **Cleaning**: Keep the device clean from dirt, grease, and debris to prevent interference with moving parts and to allow for accurate inspections.

5. **Repair and Replacement**: Promptly repair or replace any damaged or worn components. Use only manufacturer-approved parts to maintain device integrity.

6. **Calibration**: Ensure any measuring or weighing components are calibrated regularly to maintain accuracy.

7. **Documentation**: Maintain detailed records of inspections, maintenance, repairs, and tests. This helps track the device's condition and compliance with safety regulations.

8. **Training**: Ensure operators are trained in proper use and maintenance procedures to prevent misuse and damage.

9. **Compliance**: Adhere to relevant industry standards and regulations, such as those from OSHA or ASME, to ensure safety and legal compliance.

10. **Storage**: Store devices properly when not in use to prevent damage from environmental factors.

Regular maintenance of below-the-hook lifting devices is crucial for operational safety and longevity.

What are the common types of below-the-hook lifting devices?

Common types of below-the-hook lifting devices include:

1. **Lifting Beams**: These are horizontal beams that distribute the load across multiple points, reducing stress on the load and crane. They are ideal for handling long or flexible loads.

2. **Spreader Bars**: Similar to lifting beams, spreader bars use a two-point suspension to spread the load, minimizing bending forces. They are often used for wide or heavy loads.

3. **C-Hooks**: Designed for lifting coils of materials like steel or wire, C-hooks support the load from the inside, allowing for easy maneuvering and placement.

4. **Plate Clamps**: These devices grip the edges of metal plates, allowing for vertical or horizontal lifting. They are commonly used in steel fabrication and construction.

5. **Sheet Lifters**: Specifically designed for lifting sheets of metal or other materials, these devices often use suction or mechanical grips to secure the load.

6. **Vacuum Lifters**: Utilizing suction pads, vacuum lifters are ideal for handling non-porous materials like glass or metal sheets, providing a secure grip without damaging the surface.

7. **Pallet Lifters**: These are used to lift and transport pallets without the need for a forklift, often featuring adjustable forks to accommodate different pallet sizes.

8. **Drum Lifters**: Designed to handle cylindrical drums, these devices can lift, tilt, and pour contents as needed, often using a clamping mechanism.

9. **Tongs and Grabs**: These devices use mechanical or hydraulic action to grip and lift irregularly shaped loads, such as logs or scrap metal.

10. **Magnets**: Electromagnetic or permanent magnets are used to lift ferrous materials, providing a quick and efficient method for handling metal loads.

Each type of device is selected based on the specific requirements of the load, ensuring safe and efficient lifting operations.

How do you ensure the safe operation of below-the-hook lifting devices?

To ensure the safe operation of below-the-hook lifting devices, follow these key practices:

1. **Inspection and Maintenance**: Conduct regular inspections before each use to check for wear, damage, or deformation. Follow a scheduled maintenance program as per the manufacturer's guidelines to ensure all components are in good working condition.

2. **Training and Certification**: Ensure that all operators are properly trained and certified in the use of below-the-hook lifting devices. Training should cover device operation, safety protocols, and emergency procedures.

3. **Load Assessment**: Verify the weight and balance of the load to ensure it does not exceed the device's rated capacity. Use appropriate rigging techniques to secure the load properly.

4. **Device Selection**: Choose the right lifting device for the specific load and application. Consider factors such as load type, weight, and environmental conditions.

5. **Operational Procedures**: Establish and follow standard operating procedures (SOPs) for lifting operations. This includes clear communication among team members and adherence to safety protocols.

6. **Safety Features**: Utilize devices equipped with safety features such as load indicators, limit switches, and locking mechanisms to prevent accidental release or overload.

7. **Environmental Considerations**: Assess the work environment for potential hazards such as overhead obstructions, weather conditions, and ground stability. Implement measures to mitigate these risks.

8. **Regulatory Compliance**: Adhere to relevant industry standards and regulations, such as those set by OSHA or ANSI, to ensure compliance with safety requirements.

9. **Emergency Preparedness**: Develop and communicate emergency response plans in case of equipment failure or accidents. Ensure that all personnel are familiar with these procedures.

10. **Documentation**: Maintain detailed records of inspections, maintenance, training, and incident reports to track compliance and identify areas for improvement.