Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Material Handling

- Lifting Pulling Positioning

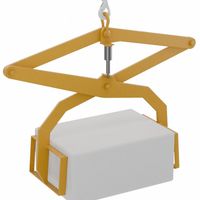

- Below The Hook Lifting Devices

- Bale Die Lifters

.....Read More

Frequently Asked Questions

What are bale and die lifters used for?

Bale and die lifters are specialized tools used in industrial and manufacturing settings to facilitate the handling and movement of heavy materials and equipment.

Bale lifters are primarily used in the textile, agricultural, and recycling industries to lift and transport bales of materials such as cotton, hay, or compacted waste. These lifters are designed to securely grip and elevate bales, allowing for efficient stacking, loading, and unloading. They help reduce manual labor, increase productivity, and enhance safety by minimizing the risk of injury associated with manual handling of heavy bales.

Die lifters, on the other hand, are used in the metalworking and manufacturing industries to handle heavy dies and molds. These lifters are essential in operations involving stamping, forging, and injection molding, where dies need to be frequently changed or repositioned. Die lifters facilitate the smooth and safe movement of dies within presses or between storage and operational areas. They help reduce downtime during die changes, improve workflow efficiency, and ensure the safety of workers by minimizing the need for manual lifting and positioning of heavy dies.

Both bale and die lifters are crucial for optimizing operational efficiency, ensuring worker safety, and reducing the physical strain associated with handling heavy loads in industrial environments.

How do bale lifting clamps work?

Bale lifting clamps are specialized attachments used with forklifts or cranes to handle and transport bales of materials such as cotton, hay, paper, or textiles. These clamps work by securely gripping the bales without the need for pallets, allowing for efficient and safe movement.

The clamps consist of two main arms that are hydraulically operated. When activated, these arms move towards each other to grip the bale from opposite sides. The hydraulic system provides the necessary force to ensure a firm hold, preventing the bale from slipping during lifting or transport. The pressure applied by the clamps can often be adjusted to accommodate different bale sizes and weights, ensuring that the material is not damaged during handling.

The design of the clamp arms can vary depending on the type of bale being handled. For instance, some clamps have smooth surfaces to prevent damage to delicate materials, while others may have textured surfaces for a better grip on slippery or heavy bales. The arms are typically made from durable materials like steel to withstand the stresses of lifting and transporting heavy loads.

Bale lifting clamps are attached to the forklift or crane via a quick-attach system, allowing for easy installation and removal. This versatility makes them suitable for various industrial applications, including agriculture, recycling, and manufacturing.

In operation, the forklift or crane operator positions the clamp around the bale, activates the hydraulic system to secure the load, and then lifts and transports the bale to the desired location. This method enhances efficiency by reducing the need for manual handling and minimizing the risk of injury or product damage.

What materials can be lifted with bale lifters?

Bale lifters are versatile tools designed to handle and transport various types of baled materials efficiently. They are commonly used in agricultural, industrial, and recycling settings. The materials that can be lifted with bale lifters include:

1. **Hay and Straw Bales**: These are the most common materials handled by bale lifters. They can lift both round and square bales, which are used for animal feed and bedding.

2. **Silage Bales**: Wrapped in plastic to ferment, silage bales are heavier and require robust bale lifters for safe handling.

3. **Cotton Bales**: In the textile industry, bale lifters are used to move large cotton bales, which are compacted for transport and storage.

4. **Recyclable Materials**: Bale lifters are used in recycling facilities to handle bales of paper, cardboard, plastics, and metals, which are compacted for efficient storage and transport.

5. **Wood Shavings and Sawdust Bales**: Used in animal bedding and other applications, these bales are often handled with bale lifters.

6. **Rubber and Tire Bales**: In recycling and manufacturing, bale lifters can move bales of compressed rubber or tires.

7. **Textile and Fabric Bales**: In the garment and textile industries, bale lifters handle bales of fabric and textiles for processing and shipping.

8. **Waste and Refuse Bales**: In waste management, bale lifters are used to move compacted bales of waste materials for disposal or recycling.

Bale lifters are designed to accommodate the size, weight, and shape of these materials, ensuring safe and efficient handling. They can be attached to tractors, forklifts, or loaders, depending on the operational requirements.

What are the safety precautions for using die lifters?

1. **Training and Certification**: Ensure operators are trained and certified in using die lifters, understanding their operation, and recognizing potential hazards.

2. **Inspection and Maintenance**: Regularly inspect die lifters for wear, damage, or malfunction. Follow a maintenance schedule to ensure all components are in good working condition.

3. **Load Capacity**: Never exceed the die lifter's rated load capacity. Ensure the weight of the die is within the specified limits.

4. **Secure Attachment**: Ensure the die is securely attached to the lifter before operation. Use appropriate clamps or fasteners to prevent slippage.

5. **Work Area Safety**: Keep the work area clean and free of obstructions. Ensure adequate lighting and clear visibility for the operator.

6. **Personal Protective Equipment (PPE)**: Wear appropriate PPE, such as gloves, safety glasses, and steel-toed boots, to protect against potential hazards.

7. **Emergency Procedures**: Familiarize operators with emergency shutdown procedures and ensure easy access to emergency stop controls.

8. **Communication**: Maintain clear communication among team members during lifting operations. Use hand signals or radios if necessary.

9. **Stability and Balance**: Ensure the die is balanced and stable on the lifter to prevent tipping or shifting during movement.

10. **Environmental Conditions**: Be aware of environmental factors such as wet or slippery floors, which can affect the safety of lifting operations.

11. **Use of Guards and Barriers**: Install guards or barriers to protect operators from moving parts and to prevent unauthorized access to the lifting area.

12. **Testing and Calibration**: Regularly test and calibrate the die lifter to ensure accurate and safe operation.

13. **Documentation**: Keep detailed records of inspections, maintenance, and training to ensure compliance with safety regulations and standards.

How do you maintain bale and die lifters?

To maintain bale and die lifters effectively, follow these steps:

1. **Regular Inspection**: Conduct routine checks for wear and tear, focusing on moving parts, hydraulic systems, and structural integrity. Look for signs of rust, cracks, or deformation.

2. **Lubrication**: Apply appropriate lubricants to all moving parts, including bearings, joints, and hydraulic components, to reduce friction and prevent wear.

3. **Hydraulic System Maintenance**: Check hydraulic fluid levels regularly and replace or top up as needed. Inspect hoses and connections for leaks or damage, and ensure the hydraulic pump is functioning correctly.

4. **Cleaning**: Keep the lifters clean from dust, debris, and other contaminants that can cause blockages or damage. Use compressed air or a soft brush for cleaning hard-to-reach areas.

5. **Alignment and Calibration**: Ensure that the lifters are properly aligned and calibrated to prevent uneven wear and ensure efficient operation. Adjust settings as necessary.

6. **Fastener Tightening**: Regularly check and tighten all bolts, nuts, and screws to ensure they are secure and to prevent mechanical failures.

7. **Replacement of Worn Parts**: Replace any worn or damaged parts immediately to prevent further damage and ensure safety. Keep a stock of essential spare parts for quick replacements.

8. **Training and Safety**: Ensure that operators are well-trained in the use and maintenance of the lifters. Implement safety protocols to prevent accidents during maintenance.

9. **Documentation**: Maintain detailed records of all maintenance activities, inspections, and repairs. This helps in tracking the lifter’s condition and planning future maintenance.

10. **Professional Servicing**: Schedule regular professional servicing to address complex issues and ensure compliance with safety standards and regulations.

What are the different types of die lifting tongs?

Die lifting tongs are specialized tools used to handle and transport heavy dies safely and efficiently. The different types of die lifting tongs include:

1. **Scissor Tongs**: These tongs operate on a scissor-like mechanism, allowing them to grip the die securely. They are often used for lifting dies with a consistent shape and size.

2. **Crane Tongs**: Designed to be used with overhead cranes, these tongs can handle large and heavy dies. They often feature adjustable arms to accommodate different die sizes.

3. **Automatic Tongs**: These tongs automatically adjust to the size of the die, providing a secure grip without manual intervention. They are ideal for operations requiring frequent die changes.

4. **Adjustable Tongs**: These tongs have adjustable arms or jaws, allowing them to handle dies of various sizes. They are versatile and can be used in different applications.

5. **Magnetic Tongs**: Equipped with powerful magnets, these tongs are used for lifting ferrous metal dies. They provide a secure grip without the need for mechanical clamping.

6. **Hydraulic Tongs**: These tongs use hydraulic power to grip and lift dies. They are suitable for very heavy or large dies that require significant force to handle.

7. **Pneumatic Tongs**: Similar to hydraulic tongs, these use compressed air to operate. They are often used in environments where hydraulic systems are not feasible.

8. **Custom Tongs**: Designed for specific applications, these tongs are tailored to meet unique requirements, such as handling dies with unusual shapes or sizes.

Each type of die lifting tong is designed to meet specific operational needs, ensuring safety and efficiency in die handling processes.

How do you choose the right bale lifter for your needs?

To choose the right bale lifter, consider the following factors:

1. **Bale Type and Size**: Identify the type (round or square) and size of bales you need to handle. Different lifters are designed for specific bale dimensions and weights.

2. **Weight Capacity**: Ensure the lifter can handle the maximum weight of your bales. Check the lifting capacity to avoid overloading and potential equipment damage.

3. **Compatibility**: Verify that the bale lifter is compatible with your existing machinery, such as tractors or loaders. Check the attachment system (e.g., three-point hitch, front loader) for compatibility.

4. **Material and Build Quality**: Opt for lifters made from durable materials like high-grade steel to withstand heavy use and harsh conditions. Quality construction ensures longevity and reliability.

5. **Ease of Use**: Consider lifters with user-friendly features such as quick-attach systems, adjustable arms, and hydraulic controls for efficient operation.

6. **Terrain and Environment**: Assess the terrain where the lifter will be used. For uneven or hilly areas, choose a lifter with stability features to prevent tipping.

7. **Budget**: Determine your budget and compare options within your price range. Balance cost with quality and features to ensure value for money.

8. **Brand Reputation and Support**: Choose reputable brands known for quality and customer support. Check for warranty options and availability of spare parts.

9. **Safety Features**: Look for lifters with safety features like locking mechanisms and protective guards to prevent accidents during operation.

10. **Reviews and Recommendations**: Read reviews and seek recommendations from other users or industry experts to gauge performance and reliability.

By considering these factors, you can select a bale lifter that meets your operational needs efficiently and safely.