Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

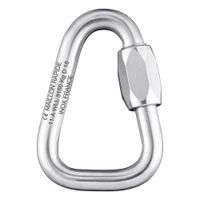

- Material Handling

- Lifting Pulling Positioning

- Lifting Rigging Hardware

- Connecting Links

.....Read More

Frequently Asked Questions

What are the different grades of connecting links used for lifting applications?

The different grades of connecting links used for lifting applications are primarily distinguished by their material strength and load-bearing capacity. Here are the common grades:

1. **Grade 30 (Proof Coil):** Made from low-carbon steel, this grade is suitable for general-purpose applications but not recommended for overhead lifting due to its lower strength.

2. **Grade 43 (High-Test):** This grade is stronger than Grade 30 and is used for load binding, towing, and logging. It is not suitable for overhead lifting.

3. **Grade 70 (Transport Chain):** Made from heat-treated carbon steel, Grade 70 is used for load securement in the transportation industry. It is not designed for overhead lifting.

4. **Grade 80 (Alloy Chain):** This is the first grade suitable for overhead lifting. Made from alloy steel, it offers high strength and durability, making it ideal for lifting slings and chain hoists.

5. **Grade 100 (Alloy Chain):** Offering 25% more strength than Grade 80, Grade 100 is used for heavy-duty lifting applications. It is made from high-strength alloy steel and is suitable for overhead lifting.

6. **Grade 120 (High-Performance Alloy Chain):** This grade provides the highest strength-to-weight ratio, offering 50% more strength than Grade 80. It is used in the most demanding lifting applications and is made from advanced alloy steel.

Each grade is marked with specific identifiers and must comply with industry standards such as ASTM, ISO, or EN to ensure safety and reliability in lifting operations. Proper selection based on the load requirements and application is crucial to ensure safety and efficiency.

How do you determine the appropriate size of a connecting link for a specific load?

To determine the appropriate size of a connecting link for a specific load, follow these steps:

1. **Identify Load Requirements**: Determine the maximum load the connecting link will need to support. Consider dynamic factors such as shock loads, vibration, and potential overloads.

2. **Material Selection**: Choose a material suitable for the environment and load conditions. Common materials include steel, stainless steel, and alloy steel, each offering different strength and corrosion resistance.

3. **Safety Factor**: Apply a safety factor to the maximum load to account for uncertainties. A typical safety factor ranges from 3 to 5, depending on the application and risk level.

4. **Calculate Working Load Limit (WLL)**: Multiply the maximum load by the safety factor to get the WLL. This is the maximum load the connecting link should handle under normal conditions.

5. **Consult Manufacturer Specifications**: Refer to manufacturer catalogs or standards (such as ASME, ASTM, or ISO) to find connecting links that meet or exceed the calculated WLL. Check for specifications like breaking strength and fatigue resistance.

6. **Size and Design Considerations**: Ensure the connecting link fits the dimensional requirements of the application, including pin size, link length, and width. Consider ease of assembly and disassembly.

7. **Environmental Factors**: Consider environmental conditions such as temperature, humidity, and exposure to chemicals, which may affect material performance and longevity.

8. **Testing and Certification**: Ensure the connecting link is tested and certified for the intended load and application. Look for certifications from recognized bodies to ensure compliance with safety standards.

9. **Review and Verification**: Have a qualified engineer review the selection to verify that all factors have been considered and the chosen link is appropriate for the application.

By following these steps, you can select a connecting link that safely and effectively supports the intended load.

What safety standards should be followed when using connecting links for lifting?

When using connecting links for lifting, adhere to the following safety standards:

1. **Material and Design Compliance**: Ensure connecting links are made from high-strength materials like alloy steel and comply with relevant standards such as ASME B30.9 or EN 1677.

2. **Load Rating**: Verify the working load limit (WLL) of the connecting link matches or exceeds the load requirements. Never exceed the WLL.

3. **Inspection**: Conduct regular inspections for wear, deformation, cracks, corrosion, or other damage. Remove from service if defects are found.

4. **Compatibility**: Ensure compatibility with other lifting components, such as chains, hooks, and slings, to prevent mismatched connections that could lead to failure.

5. **Proper Assembly**: Follow manufacturer instructions for assembly. Ensure all components are correctly aligned and secured.

6. **Environmental Considerations**: Consider environmental factors like temperature, chemicals, or moisture that may affect the integrity of the connecting link.

7. **Training**: Ensure personnel are trained in the proper use, inspection, and maintenance of connecting links.

8. **Documentation**: Maintain records of inspections, maintenance, and any incidents involving the connecting links.

9. **Marking and Identification**: Ensure connecting links are clearly marked with the WLL, manufacturer’s identification, and traceability codes.

10. **Storage**: Store connecting links in a clean, dry environment to prevent damage and corrosion.

11. **Avoid Shock Loading**: Prevent sudden loading or impact forces that exceed the WLL.

12. **Use of Safety Pins or Locks**: If applicable, use safety pins or locks to secure the connection and prevent accidental disconnection.

13. **Regulatory Compliance**: Follow local and international regulations and standards relevant to lifting operations.

14. **Periodic Testing**: Conduct periodic load testing as required by regulations or manufacturer guidelines to ensure ongoing safety and performance.

How often should connecting links be inspected for wear and damage?

Connecting links should be inspected for wear and damage at regular intervals to ensure safety and functionality. The frequency of these inspections depends on several factors, including the type of equipment, the environment in which it operates, and the manufacturer's recommendations. Generally, inspections should occur:

1. **Before Each Use**: A quick visual inspection should be conducted before each use to identify any obvious signs of wear or damage.

2. **Weekly or Monthly**: For equipment that is used frequently or operates in harsh conditions, a more thorough inspection should be conducted weekly or monthly. This includes checking for signs of wear, corrosion, deformation, or any other damage.

3. **Quarterly or Biannually**: For equipment used less frequently or in less demanding environments, inspections can be scheduled quarterly or biannually. This should include a detailed examination of all components.

4. **Annually**: An annual inspection should be conducted regardless of usage frequency. This comprehensive inspection should be performed by a qualified professional to ensure all components are in good working condition.

5. **After Unusual Events**: Inspections should also be conducted after any unusual events, such as overloading, impacts, or exposure to extreme conditions, which could compromise the integrity of the connecting links.

6. **According to Manufacturer's Guidelines**: Always follow the manufacturer's guidelines for inspection frequency and procedures, as they are tailored to the specific equipment and its intended use.

Regular inspections help in identifying potential issues early, preventing equipment failure, and ensuring safety.

What are the differences between lifting connecting links and load-securing connecting links?

Lifting connecting links and load-securing connecting links serve different purposes and have distinct characteristics:

1. **Purpose**:

- **Lifting Connecting Links**: These are used in lifting operations to connect various components of a lifting assembly, such as chains, hooks, and slings. They are designed to handle dynamic loads and ensure safe lifting of heavy objects.

- **Load-Securing Connecting Links**: These are used to secure loads during transportation. They connect tie-downs, chains, or straps to anchor points, ensuring the load remains stable and secure during transit.

2. **Design and Construction**:

- **Lifting Connecting Links**: Typically made from high-strength materials like alloy steel to withstand the stresses of lifting. They are often heat-treated for added durability and are designed to handle specific load capacities.

- **Load-Securing Connecting Links**: Made from durable materials but may not require the same high-strength specifications as lifting links. They focus on resisting tension and ensuring stability rather than lifting.

3. **Safety Standards**:

- **Lifting Connecting Links**: Must comply with stringent safety standards and regulations, such as those set by OSHA or ASME, to ensure they can safely handle the specified loads.

- **Load-Securing Connecting Links**: Must meet standards like those from the Department of Transportation (DOT) or other relevant bodies, focusing on securing loads during transport.

4. **Load Capacity**:

- **Lifting Connecting Links**: Rated for specific Working Load Limits (WLL) and are tested for breaking strength to ensure safety during lifting operations.

- **Load-Securing Connecting Links**: Rated for tension and securing strength, focusing on preventing load shifts rather than lifting.

5. **Usage Environment**:

- **Lifting Connecting Links**: Used in construction, manufacturing, and other industries where lifting is required.

- **Load-Securing Connecting Links**: Used in logistics, shipping, and transportation sectors.

How do you properly install and secure a connecting link to a master link?

1. **Selection**: Choose a connecting link compatible with the master link and chain size. Ensure it meets the load and application requirements.

2. **Inspection**: Examine the connecting and master links for any damage, wear, or defects. Replace if necessary.

3. **Alignment**: Align the connecting link with the master link and chain ends. Ensure the chain is tension-free to facilitate easy installation.

4. **Insertion**: Insert the connecting link into the master link and chain ends. For a slip-fit link, slide it into place; for a press-fit link, use a chain press tool.

5. **Securing**: Attach the retaining clip or cotter pin. For a clip-type link, position the open end of the clip opposite the chain's direction of travel. For a rivet-type link, use a rivet tool to peen the pins securely.

6. **Verification**: Check the installation by ensuring the link moves freely without binding. Verify the clip or rivet is secure and properly seated.

7. **Lubrication**: Apply appropriate lubricant to the connecting link to reduce friction and wear.

8. **Testing**: Run the chain slowly to ensure smooth operation and proper alignment. Listen for unusual noises or vibrations.

9. **Regular Inspection**: Periodically inspect the connecting link for wear, corrosion, or damage. Replace if necessary to maintain chain integrity.

10. **Documentation**: Record the installation date and any maintenance actions for future reference.

By following these steps, you ensure a secure and reliable connection between the connecting link and master link, enhancing the chain's performance and longevity.

What are the common materials used in manufacturing connecting links for lifting applications?

Common materials used in manufacturing connecting links for lifting applications include:

1. **Alloy Steel**: Known for its high strength-to-weight ratio, alloy steel is often used for heavy-duty lifting applications. It offers excellent toughness and resistance to wear and fatigue.

2. **Carbon Steel**: This material is widely used due to its affordability and adequate strength for many lifting applications. It is often heat-treated to enhance its mechanical properties.

3. **Stainless Steel**: Preferred for its corrosion resistance, stainless steel is used in environments where exposure to moisture or chemicals is a concern. It is ideal for marine and outdoor applications.

4. **Forged Steel**: Forged steel connecting links are known for their superior strength and durability. The forging process aligns the grain structure, enhancing the material's mechanical properties.

5. **Cast Iron**: While not as common as steel, cast iron is used in some applications where high compressive strength is required. However, it is more brittle compared to steel.

6. **Aluminum Alloys**: Used in applications where weight is a critical factor, aluminum alloys offer a good balance of strength and lightness. They are also resistant to corrosion.

7. **Titanium**: Known for its high strength, low density, and excellent corrosion resistance, titanium is used in specialized applications where performance is critical, despite its higher cost.

8. **Synthetic Materials**: Advanced polymers and composites are increasingly used for lightweight and corrosion-resistant applications. They are suitable for specific environments and load requirements.

Each material is selected based on factors such as load capacity, environmental conditions, cost, and specific application requirements.