Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

- Milling

- Milling Cutters

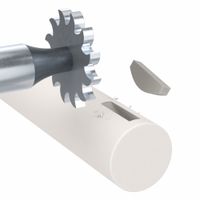

- Keyseat Milling Cutters

.....Read More

Frequently Asked Questions

What are keyseat milling cutters used for?

Keyseat milling cutters are specialized tools used in machining to create keyseats or keyways, which are slots or grooves cut into a workpiece. These slots are designed to accommodate a key, a small metal component that fits into the keyway to lock two parts together, ensuring they rotate in unison. This is crucial in mechanical systems where torque transmission between shafts and gears, pulleys, or other components is required.

Keyseat milling cutters are typically used in the following applications:

1. **Shafts and Hubs**: They are commonly used to cut keyways in shafts and hubs, allowing for the secure attachment of gears, pulleys, or couplings. This ensures that the components do not slip on the shaft during operation.

2. **Precision Engineering**: In industries requiring high precision, such as aerospace and automotive, keyseat milling cutters are used to produce accurate and consistent keyways, which are essential for the reliable performance of mechanical systems.

3. **Repair and Maintenance**: These cutters are also used in repair and maintenance operations to refurbish worn keyways or to create new ones when replacing components.

4. **Custom Machinery**: In custom machinery manufacturing, keyseat milling cutters are employed to create bespoke keyways tailored to specific design requirements.

Keyseat milling cutters come in various shapes and sizes, including straight, staggered tooth, and T-slot cutters, to accommodate different keyway dimensions and material types. They are typically made from high-speed steel or carbide to withstand the rigors of cutting through tough materials. The choice of cutter depends on the material being machined, the required keyway dimensions, and the specific application.

How do you choose the right size of a keyseat milling cutter?

To choose the right size of a keyseat milling cutter, consider the following factors:

1. **Keyseat Dimensions**: Match the cutter's diameter and width to the keyseat's required dimensions. The cutter's width should be slightly less than the keyseat width to allow for finishing passes.

2. **Material**: Consider the material of the workpiece. Harder materials may require cutters made from high-speed steel or carbide for durability and efficiency.

3. **Cutter Type**: Choose between straight or staggered tooth cutters based on the finish and cutting speed required. Staggered tooth cutters provide better chip clearance and smoother finishes.

4. **Machine Capability**: Ensure the milling machine can accommodate the cutter's size and has the necessary power and speed settings.

5. **Depth of Cut**: Select a cutter that can achieve the desired depth in a single pass if possible, to maintain accuracy and reduce machining time.

6. **Tolerance and Finish**: Consider the required tolerances and surface finish. A finer finish may require a smaller cutter for more precise control.

7. **Shank Size**: Ensure the cutter's shank fits the machine's spindle or collet.

8. **Cutting Speed and Feed Rate**: Choose a cutter that can operate at the optimal speed and feed rate for the material and machine.

9. **Cost and Availability**: Consider the cost-effectiveness and availability of the cutter, balancing quality with budget constraints.

10. **Manufacturer Recommendations**: Refer to the manufacturer's guidelines for specific cutter recommendations based on application and material.

By evaluating these factors, you can select a keyseat milling cutter that meets the specific requirements of your machining task.

What materials are keyseat milling cutters made from?

Keyseat milling cutters are typically made from high-speed steel (HSS), carbide, and cobalt alloys. High-speed steel is popular due to its toughness and ability to withstand high temperatures without losing hardness, making it suitable for general-purpose cutting. Carbide cutters, often made from tungsten carbide, are harder and more wear-resistant than HSS, allowing for faster cutting speeds and longer tool life, especially in high-volume production or when cutting harder materials. Cobalt alloys, which are essentially HSS with added cobalt, offer enhanced heat resistance and durability, making them ideal for cutting tougher materials. These materials are often coated with titanium nitride (TiN), titanium carbonitride (TiCN), or aluminum titanium nitride (AlTiN) to further improve wear resistance and reduce friction.

How do you maintain and sharpen keyseat milling cutters?

To maintain and sharpen keyseat milling cutters, follow these steps:

1. **Inspection**: Regularly inspect the cutter for wear, damage, or dullness. Check for chipped or broken teeth and ensure the cutter is not bent or warped.

2. **Cleaning**: Clean the cutter thoroughly to remove any debris, chips, or residue. Use a brush and appropriate cleaning solution to ensure all surfaces are free from contaminants.

3. **Sharpening**: Use a tool and cutter grinder for sharpening. Secure the cutter in the grinder's fixture, ensuring it is aligned correctly. Adjust the grinder to match the cutter's original geometry, focusing on the rake and clearance angles.

4. **Grinding**: Begin with the face of the teeth. Use a fine-grit grinding wheel to remove minimal material, maintaining the original tooth profile. Grind evenly to ensure balance and avoid altering the cutter's dimensions.

5. **Flute Sharpening**: If necessary, sharpen the flutes by grinding the inside edge. This requires precision to maintain the correct helix angle and flute geometry.

6. **Balancing**: After sharpening, check the cutter for balance. An imbalanced cutter can cause vibrations and reduce machining accuracy. Adjust as needed to ensure even weight distribution.

7. **Lubrication**: Apply a light coat of oil to prevent rust and corrosion. Ensure the cutter is dry before storage.

8. **Storage**: Store the cutter in a protective case or holder to prevent damage. Keep it in a dry, temperature-controlled environment.

9. **Documentation**: Maintain records of sharpening and maintenance activities to track the cutter's condition and performance over time.

By following these steps, you can extend the life of keyseat milling cutters and ensure optimal performance.

What are the differences between keyseat milling cutters and other types of milling cutters?

Keyseat milling cutters, also known as keyway cutters, are specialized tools designed specifically for cutting keyways, which are slots in shafts or hubs that accommodate a key to prevent relative rotation. The primary differences between keyseat milling cutters and other types of milling cutters are as follows:

1. **Design and Shape**: Keyseat cutters typically have a cylindrical shape with a flat bottom and cutting edges on the periphery and face, allowing them to cut precise slots. Other milling cutters, like end mills or face mills, come in various shapes such as flat, ball-nose, or corner-radius, designed for different types of cuts and surface finishes.

2. **Application**: Keyseat cutters are specifically used for creating keyways, whereas other milling cutters are used for a broader range of applications, including contouring, slotting, and surface finishing.

3. **Cutting Edges**: Keyseat cutters have cutting edges optimized for slotting operations, providing clean and accurate keyways. Other milling cutters may have different edge geometries suited for their specific tasks, such as roughing or finishing.

4. **Size and Diameter**: Keyseat cutters are often smaller in diameter to fit into narrow slots, while other milling cutters can vary widely in size depending on the application, from small-diameter end mills to large face mills.

5. **Material and Coating**: While both keyseat and other milling cutters can be made from similar materials like high-speed steel or carbide, the coatings and specific material compositions may differ based on the intended use and material being machined.

6. **Mounting and Operation**: Keyseat cutters are typically mounted on an arbor and used in horizontal milling machines, whereas other milling cutters can be used in both horizontal and vertical milling machines, depending on their design and purpose.

Can keyseat milling cutters be used on manual milling machines?

Yes, keyseat milling cutters can be used on manual milling machines. These cutters are specifically designed to cut keyseats or keyways, which are slots in shafts that accommodate keys to prevent relative rotation between components. When using a keyseat milling cutter on a manual milling machine, several factors should be considered to ensure precision and safety:

1. **Machine Setup**: Proper alignment of the workpiece and the cutter is crucial. The workpiece should be securely clamped to prevent movement during the milling process. The milling machine's spindle should be aligned perpendicular to the workpiece surface.

2. **Cutter Selection**: Choose the appropriate keyseat cutter based on the material of the workpiece and the dimensions of the keyseat required. The cutter's diameter and width should match the specifications of the keyway.

3. **Speed and Feed**: Adjust the spindle speed and feed rate according to the material being machined and the cutter's specifications. Proper speed and feed ensure efficient cutting and prolong the cutter's life.

4. **Depth of Cut**: Gradually increase the depth of cut to avoid overloading the cutter and the machine. Multiple passes may be necessary to achieve the desired keyseat depth.

5. **Lubrication and Cooling**: Use appropriate cutting fluids to reduce friction, dissipate heat, and improve the surface finish. This also helps in extending the tool life.

6. **Safety Precautions**: Always wear appropriate personal protective equipment (PPE) and follow safety guidelines to prevent accidents. Ensure that all machine guards are in place and functioning.

By carefully considering these factors, keyseat milling cutters can be effectively and safely used on manual milling machines to produce precise keyways.

What are the common sizes and specifications of keyseat milling cutters?

Keyseat milling cutters, also known as keyway cutters, are specialized tools used to cut keyways in shafts and other components. Common sizes and specifications include:

1. **Diameter**: Typically ranges from 1/8 inch to 1 inch, with metric sizes available from 3 mm to 25 mm.

2. **Width**: The width of the cutter corresponds to the width of the keyway being cut. Standard widths range from 1/16 inch to 1/2 inch, with metric equivalents from 1.5 mm to 12 mm.

3. **Shank Size**: Shank diameters are usually standardized to fit common machine tool holders, often 1/4 inch, 3/8 inch, 1/2 inch, or 3/4 inch. Metric shanks are typically 6 mm, 10 mm, or 12 mm.

4. **Material**: Commonly made from high-speed steel (HSS) for general-purpose cutting, or carbide for harder materials and longer tool life.

5. **Coatings**: May include titanium nitride (TiN), titanium carbonitride (TiCN), or aluminum titanium nitride (AlTiN) to enhance wear resistance and performance.

6. **Number of Flutes**: Typically 2 to 4 flutes, with more flutes providing a smoother finish and fewer flutes allowing for faster material removal.

7. **Cutting Edge Style**: Can be straight or staggered tooth, with staggered teeth providing better chip evacuation and reduced cutting forces.

8. **Overall Length**: Varies based on application, generally ranging from 2 inches to 6 inches.

9. **Tolerance**: Precision keyseat cutters are manufactured to tight tolerances to ensure accurate keyway dimensions, often within ±0.001 inch.

These specifications can vary based on the manufacturer and specific application requirements.