Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What are the different types of milling cutters?

Milling cutters are essential tools in the machining process, used to remove material from a workpiece. They come in various types, each designed for specific applications:

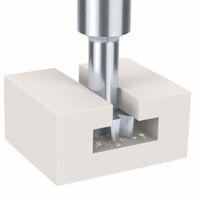

1. **End Mills**: These are versatile cutters used for profile milling, face milling, and plunging. They come in various shapes like square, ball-nose, and corner radius.

2. **Face Mills**: Designed for cutting large, flat surfaces, face mills have multiple cutting edges and are used for high-speed machining.

3. **Slab Mills**: Used for heavy cutting of large and flat surfaces, slab mills have a wide cutting surface and are ideal for removing large amounts of material.

4. **Side and Face Cutters**: These have cutting teeth on the periphery and sides, allowing them to cut slots and grooves.

5. **Fly Cutters**: Simple single-point cutters used for machining large, flat surfaces. They are adjustable and can be used for light to medium-duty tasks.

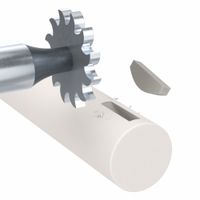

6. **Hollow Mills**: These are used for machining cylindrical surfaces and are ideal for creating shafts and similar components.

7. **Thread Mills**: Designed for cutting threads, these cutters can produce both internal and external threads with precision.

8. **Gear Cutters**: Used for cutting gear teeth, these come in various forms to accommodate different gear profiles.

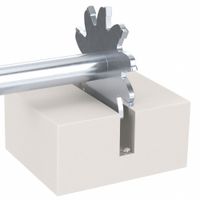

9. **T-Slot Cutters**: Specifically designed to cut T-slots in machine tables and other components.

10. **Dovetail Cutters**: Used to create dovetail slots, these cutters have angled cutting edges.

11. **Ball Nose Cutters**: Ideal for 3D contouring and machining complex surfaces, these have a rounded end.

12. **Roughing End Mills**: Also known as hog mills, these have serrated cutting edges for rapid material removal.

Each type of milling cutter is designed to perform specific tasks, and selecting the right one depends on the material, the desired finish, and the complexity of the workpiece.

How do I choose the right milling cutter for my project?

1. **Material Type**: Identify the material you will be cutting (e.g., steel, aluminum, wood). Different materials require different cutter materials and coatings.

2. **Cutter Material**: Choose the cutter material based on the workpiece material. Common options include high-speed steel (HSS), carbide, and cobalt. Carbide is suitable for hard materials, while HSS is more economical for softer materials.

3. **Coating**: Select a coating to enhance performance and tool life. Titanium nitride (TiN), titanium carbonitride (TiCN), and aluminum titanium nitride (AlTiN) are popular coatings that reduce friction and increase wear resistance.

4. **Cutter Type**: Decide between end mills, face mills, slab mills, etc., based on the operation. End mills are versatile for side milling, slotting, and contouring, while face mills are ideal for surface finishing.

5. **Number of Flutes**: Choose the number of flutes based on the material and operation. Fewer flutes (2-3) are better for softer materials and provide better chip clearance, while more flutes (4-6) are suitable for harder materials and offer a smoother finish.

6. **Cutter Diameter**: Select the appropriate diameter for the desired cut width and depth. Larger diameters provide more stability and faster material removal.

7. **Helix Angle**: Consider the helix angle, which affects chip evacuation and surface finish. A higher helix angle (e.g., 45 degrees) offers better surface finish and chip evacuation, while a lower angle (e.g., 30 degrees) provides more strength.

8. **Cutting Parameters**: Determine the appropriate speed, feed rate, and depth of cut based on the cutter and material specifications.

9. **Machine Compatibility**: Ensure the cutter is compatible with your milling machine’s spindle size and power capacity.

10. **Budget**: Balance performance needs with budget constraints, considering the cost of the cutter and potential tool life.

What materials are milling cutters made from?

Milling cutters are typically made from a variety of materials, each chosen for its specific properties that suit different milling applications. The most common materials include:

1. **High-Speed Steel (HSS):** Known for its toughness and ability to withstand high temperatures without losing hardness, HSS is widely used for general-purpose milling. It is cost-effective and can be easily sharpened.

2. **Cobalt Steel Alloys:** These are variations of HSS with added cobalt, which enhances heat resistance and hardness. They are suitable for cutting harder materials and are more durable than standard HSS.

3. **Carbide:** Tungsten carbide is extremely hard and wear-resistant, making it ideal for high-speed applications and cutting abrasive materials. Carbide cutters maintain a sharp edge longer than HSS and are often used in CNC machines for precision work.

4. **Ceramics:** Ceramic cutters are used for high-speed machining of hard materials. They offer excellent heat resistance and can operate at higher speeds than carbide, but they are more brittle and prone to chipping.

5. **Cermet:** A composite material made from ceramic and metallic materials, cermet cutters provide a balance between the toughness of metals and the heat resistance of ceramics. They are used for finishing operations.

6. **Diamond:** Polycrystalline diamond (PCD) cutters are used for non-ferrous and abrasive materials. They offer superior wear resistance and are ideal for high-precision applications.

7. **Coated Tools:** Many milling cutters are coated with materials like titanium nitride (TiN), titanium carbonitride (TiCN), or aluminum oxide (Al2O3) to enhance performance. Coatings reduce friction, increase hardness, and extend tool life.

Each material offers distinct advantages, and the choice depends on factors such as the material being machined, the desired finish, and the specific milling operation.

How do I maintain and sharpen milling cutters?

To maintain and sharpen milling cutters, follow these steps:

1. **Regular Inspection**: Frequently check the cutters for wear, damage, or dullness. Look for signs like chipped edges or uneven cutting surfaces.

2. **Cleaning**: After each use, clean the cutters to remove debris, chips, and coolant residues. Use a soft brush or compressed air to avoid damaging the cutting edges.

3. **Proper Storage**: Store cutters in a dry, organized environment. Use protective cases or racks to prevent contact with other tools, which can cause damage.

4. **Sharpening**:

- **Identify Dullness**: If the cutter requires more force or produces poor finishes, it likely needs sharpening.

- **Use a Tool and Cutter Grinder**: Secure the cutter in the grinder. Ensure the correct angles are set for the specific cutter type.

- **Grinding Process**: Gently grind the cutting edges, maintaining the original geometry. Use a fine-grit wheel for a smooth finish.

- **Coolant Application**: Apply coolant during grinding to prevent overheating, which can alter the cutter's temper and hardness.

- **Check for Burrs**: After grinding, inspect for burrs and remove them with a fine stone or file.

5. **Balancing**: After sharpening, ensure the cutter is balanced to prevent vibration during use, which can lead to poor performance and further wear.

6. **Lubrication**: Apply a light coat of oil to prevent rust and corrosion, especially if the cutter will be stored for an extended period.

7. **Professional Services**: For complex or high-precision cutters, consider professional sharpening services to ensure optimal performance and longevity.

By following these steps, you can maintain the efficiency and lifespan of your milling cutters.

What is the difference between CNC and manual milling machines?

CNC (Computer Numerical Control) milling machines and manual milling machines differ primarily in their operation and capabilities.

CNC milling machines are automated and controlled by computer programs, allowing for precise and complex machining tasks. They can execute pre-programmed sequences of machine control commands, enabling them to produce intricate parts with high accuracy and repeatability. CNC machines can operate continuously without human intervention, making them ideal for high-volume production. They also offer the ability to store and recall programs for different parts, enhancing efficiency and reducing setup time.

In contrast, manual milling machines require a skilled operator to control the machine manually. The operator adjusts the machine's controls to move the cutting tool and workpiece, relying on their expertise to achieve the desired dimensions. Manual milling is more labor-intensive and time-consuming, suitable for low-volume production or custom work. It allows for greater flexibility and immediate adjustments during the machining process, which can be advantageous for prototyping or one-off projects.

CNC machines generally offer higher precision and consistency compared to manual machines, as they eliminate human error. They can also handle more complex geometries and multi-axis operations that would be challenging or impossible with manual machines. However, CNC machines require a significant initial investment and programming knowledge, whereas manual machines are typically less expensive and easier to learn.

In summary, CNC milling machines are best suited for high-precision, high-volume production with complex designs, while manual milling machines are more appropriate for smaller-scale, custom, or prototype work where flexibility and immediate control are needed.

How do chamfer milling cutters work?

Chamfer milling cutters are specialized tools used in machining to create a beveled edge or chamfer on a workpiece. These cutters are typically designed with an angled cutting edge that corresponds to the desired chamfer angle, commonly 45 degrees, but other angles are also available depending on the application.

The operation begins by securing the workpiece in a milling machine. The chamfer milling cutter is then mounted onto the machine's spindle. As the spindle rotates, the cutter's angled edges engage the workpiece material. The machine operator or CNC program controls the feed rate and depth of cut to ensure precision and consistency.

Chamfer milling can be performed on various materials, including metals, plastics, and composites. The process involves removing material from the edge of the workpiece to create a sloped surface, which can serve multiple purposes: improving aesthetics, removing sharp edges for safety, preparing edges for welding, or facilitating assembly by easing the insertion of parts.

The effectiveness of chamfer milling depends on several factors, including the cutter's material, coating, and geometry, as well as the machine's speed, feed rate, and stability. Carbide and high-speed steel are common materials for chamfer cutters due to their durability and cutting efficiency. Coatings like TiN or TiAlN can enhance performance by reducing wear and heat buildup.

In summary, chamfer milling cutters work by rotating against a workpiece to remove material and create a beveled edge. The process is controlled by adjusting the machine's parameters to achieve the desired chamfer size and finish, making it a versatile and essential operation in manufacturing and metalworking.

What are the applications of dovetail milling cutters?

Dovetail milling cutters are specialized tools used primarily in machining operations to create dovetail slots, which are essential for various mechanical and structural applications. These cutters are designed to produce angled slots that allow for the interlocking of components, providing a secure and precise fit. Here are some key applications:

1. **Machine Tool Manufacturing**: Dovetail slots are commonly used in the construction of machine tool components, such as slides and ways, to ensure precise alignment and smooth movement. The dovetail design provides stability and accuracy, which are critical in machining operations.

2. **Fixture and Jig Construction**: In manufacturing, fixtures and jigs often incorporate dovetail slots to allow for adjustable and repeatable positioning of workpieces. This ensures consistency and efficiency in production processes.

3. **Woodworking**: Dovetail joints are a hallmark of quality woodworking, used in cabinetry and furniture making. Dovetail milling cutters enable the creation of these joints, which are valued for their strength and aesthetic appeal.

4. **Aerospace and Automotive Industries**: These industries utilize dovetail slots in the assembly of components that require precise alignment and secure fastening. The dovetail design is particularly useful in applications subject to high stress and vibration.

5. **Tool and Die Making**: Dovetail cutters are used to create the precise slots needed for the assembly of dies and molds, ensuring that components fit together accurately and function as intended.

6. **Repair and Maintenance**: In maintenance operations, dovetail milling cutters are used to refurbish worn dovetail slots, restoring the functionality and precision of mechanical assemblies.

Overall, dovetail milling cutters are essential tools in industries that require precision engineering and secure component assembly, contributing to the durability and performance of various mechanical systems.