- Home

- Electrical

- Wire Cable Management

.....Read More

Cable Grips, Mesh Grips & Safety Springs

Cable Hangers, Clips & Organizers

Cable & Hose Carriers

Cable Ladder & Wire Mesh Trays

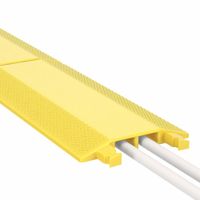

Cable Ramps & Cable Floor Covers

Cable Reels for Teaching Pendants

Cable Sleeving & Wraps

Cable Ties & Mounts

Corrugated Loom Tubing

Heat Shrink & Cold Shrink Tubing

Surface Raceways & Cable Concealers

Wireways

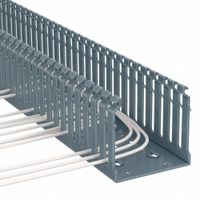

Wiring Ducts

Frequently Asked Questions

What are the best products for organizing and protecting electrical wires and cables?

How do wireways and cable ladders differ in cable management?

What are the benefits of using wire mesh trays for cable routing?

How do surface raceways help in managing cables in high-traffic areas?

What is the purpose of using corrugated loom tubing in cable management?

How do cable sleeves, wraps, and ties improve cable organization?

What are the advantages of using cable ramps and floor covers?

How do cable pulling grips and mesh grips assist in cable installation?

What is the function of heat and cold shrink tubing in cable management?

How do cable reels for teach pendants enhance safety in robotic systems?