Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electrical

- Wire Cable Management

- Cable Ramps Cable Floor Covers

.....Read More

Frequently Asked Questions

What are cable ramps and cable floor covers used for?

Cable ramps and cable floor covers are essential tools used to protect cables, wires, and hoses from damage and to prevent tripping hazards in various environments. They serve several key purposes:

1. **Protection of Cables**: Cable ramps and floor covers shield cables from physical damage caused by foot traffic, vehicles, or equipment. This protection is crucial in preventing wear and tear, which can lead to electrical failures or safety hazards.

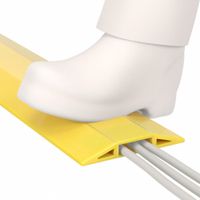

2. **Safety**: By covering cables, these devices reduce the risk of tripping accidents in areas with high foot traffic, such as events, construction sites, or office spaces. They ensure that cables do not become obstacles, thereby enhancing overall safety.

3. **Organization**: Cable ramps and covers help in organizing multiple cables, keeping them neatly arranged and preventing tangling. This organization is particularly beneficial in environments with numerous cables, such as data centers or production studios.

4. **Versatility**: These tools are used in a variety of settings, including industrial sites, outdoor events, offices, and public spaces. They are designed to accommodate different cable sizes and can be used for both temporary and permanent installations.

5. **Durability**: Made from robust materials like rubber, polyurethane, or metal, cable ramps and covers are built to withstand harsh conditions, including heavy loads and extreme weather, ensuring long-term use.

6. **Compliance**: In many regions, using cable ramps and covers is a compliance requirement to meet safety standards and regulations, particularly in workplaces and public areas.

Overall, cable ramps and floor covers are vital for maintaining the integrity of cable systems and ensuring safety in environments where cables are exposed to potential hazards.

How do you install cable ramps and covers?

1. **Assess the Area**: Identify the location where cable ramps and covers are needed. Ensure the surface is clean, dry, and free of debris to allow for proper adhesion and placement.

2. **Select Appropriate Ramps and Covers**: Choose cable ramps and covers that match the size and type of cables you need to protect. Consider the weight capacity required based on the traffic (pedestrian or vehicular) that will pass over them.

3. **Prepare the Cables**: Lay out the cables that need protection. Ensure they are untangled and positioned in a way that minimizes stress and potential damage.

4. **Position the Ramps and Covers**: Place the cable ramps and covers over the cables. Align them properly to ensure they cover the entire length of the cables. If using multiple sections, ensure they interlock or connect securely.

5. **Secure the Ramps and Covers**: Depending on the type, secure the ramps and covers using the built-in connectors, clips, or fasteners. For outdoor or high-traffic areas, consider using additional securing methods like adhesive strips or screws, if applicable.

6. **Test Stability**: Walk or drive over the ramps and covers to ensure they are stable and do not shift. Adjust as necessary to ensure a snug fit.

7. **Regular Maintenance**: Periodically check the ramps and covers for wear and tear. Ensure they remain securely in place and replace any damaged sections promptly to maintain safety and functionality.

What materials are cable ramps made from?

Cable ramps are typically made from a variety of materials, each chosen for its specific properties to ensure durability, safety, and functionality. Common materials include:

1. **Rubber**: Often used for its flexibility and durability, rubber cable ramps are resistant to weather conditions and provide excellent traction. They are ideal for both indoor and outdoor use and can withstand heavy foot and vehicle traffic.

2. **Polyurethane**: Known for its strength and lightweight properties, polyurethane is resistant to oils, chemicals, and abrasion. This makes it suitable for industrial environments where exposure to harsh substances is common.

3. **Polyethylene**: This plastic material is lightweight and resistant to impact, making it a cost-effective option for temporary or less demanding applications. It is also resistant to UV rays, which helps prevent degradation from sun exposure.

4. **PVC (Polyvinyl Chloride)**: PVC is used for its durability and resistance to chemicals and weathering. It is often used in environments where the cable ramp needs to be both strong and flexible.

5. **Aluminum**: For heavy-duty applications, aluminum is used due to its high strength-to-weight ratio. It is corrosion-resistant and can support significant weight, making it suitable for industrial and construction sites.

6. **Steel**: In some cases, steel is used for its extreme durability and load-bearing capacity. Steel cable ramps are typically used in environments where they need to withstand very heavy loads and harsh conditions.

Each material offers distinct advantages, and the choice depends on the specific requirements of the environment in which the cable ramp will be used, such as load capacity, exposure to elements, and the type of traffic it will encounter.

Are cable ramps suitable for outdoor use?

Yes, cable ramps are suitable for outdoor use. They are designed to protect cables, hoses, and wires from damage while ensuring safety for pedestrians and vehicles. Made from durable materials like rubber, polyurethane, or plastic, cable ramps are resistant to weather conditions, UV rays, and heavy loads, making them ideal for outdoor environments. They often feature non-slip surfaces to prevent accidents and are available in various sizes and configurations to accommodate different cable diameters and traffic requirements. Additionally, many cable ramps have modular designs, allowing for easy installation and customization to fit specific outdoor settings.

How do you choose the right cable ramp for your needs?

To choose the right cable ramp, consider the following factors:

1. **Load Capacity**: Determine the weight of the traffic (pedestrian, vehicle, or equipment) that will pass over the ramp. Choose a ramp with a load capacity that exceeds the heaviest expected load to ensure durability and safety.

2. **Number of Channels**: Assess how many cables or hoses need protection. Select a ramp with enough channels to accommodate all cables without overcrowding, ensuring each cable is securely housed.

3. **Channel Size**: Measure the diameter of the cables or hoses. Choose a ramp with channel dimensions that can comfortably fit the largest cable, allowing for easy placement and removal.

4. **Material**: Consider the environment where the ramp will be used. For outdoor or heavy-duty applications, opt for ramps made from durable materials like polyurethane or rubber, which offer resistance to weather and wear.

5. **Surface Type**: Evaluate the surface where the ramp will be placed. For smooth surfaces, ramps with anti-slip features or textured surfaces provide better traction and safety.

6. **Length and Width**: Ensure the ramp is long and wide enough to cover the area where cables are laid, providing complete protection and preventing tripping hazards.

7. **Modularity**: If the area is large or requires flexibility, consider modular ramps that can be connected to cover extended distances or navigate around obstacles.

8. **Visibility**: For high-traffic areas, choose ramps with bright colors or reflective strips to enhance visibility and prevent accidents.

9. **Compliance**: Ensure the ramp meets any relevant safety standards or regulations applicable to your industry or location.

10. **Budget**: Balance the features you need with your budget, ensuring you get a ramp that meets your requirements without overspending.

What is the difference between drop-over and lay-in cable ramps?

Drop-over cable ramps and lay-in cable ramps are both designed to protect cables and hoses from damage and to prevent tripping hazards, but they differ in design and application.

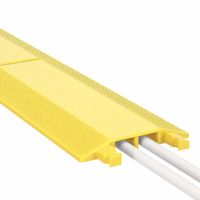

Drop-over cable ramps are designed to be placed over existing cables or hoses. They have a top section that can be lifted or is hinged, allowing the ramp to be placed directly over the cables without needing to disconnect or move them. This makes drop-over ramps ideal for temporary setups or situations where cables cannot be easily moved. They are typically used in environments where quick deployment and removal are necessary, such as events or temporary construction sites.

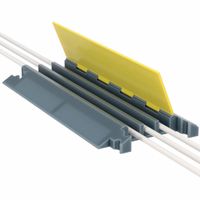

Lay-in cable ramps, on the other hand, require the cables to be placed into the ramp before it is closed. These ramps usually have a lid or cover that opens, allowing the cables to be laid inside the channel. Once the cables are in place, the lid is closed to secure them. Lay-in ramps are often used in more permanent or semi-permanent installations where cables can be disconnected or moved during setup. They provide a more secure and organized solution, as the cables are enclosed within the ramp.

In summary, the main difference lies in the method of installation: drop-over ramps are placed over existing cables, while lay-in ramps require cables to be placed inside them. This affects their suitability for different applications, with drop-over ramps being more suited for temporary use and lay-in ramps for more permanent setups.

Are cable ramps ADA compliant?

Cable ramps can be ADA compliant if they meet specific criteria set by the Americans with Disabilities Act (ADA). To be ADA compliant, cable ramps must ensure accessibility for individuals with disabilities, particularly those using wheelchairs or other mobility devices. Key factors include:

1. **Slope and Gradient**: The ramp should have a gentle slope, ideally a 1:12 ratio, meaning for every inch of height, there should be at least 12 inches of ramp run. This ensures ease of access for wheelchair users.

2. **Width**: The ramp should be wide enough to accommodate wheelchairs, typically at least 36 inches wide.

3. **Surface**: The surface of the ramp should be stable, firm, and slip-resistant to prevent accidents.

4. **Edge Protection**: Ramps should have edge protection to prevent wheels from slipping off.

5. **Transitions**: The transitions at the top and bottom of the ramp should be smooth to prevent tripping hazards.

6. **Weight Capacity**: The ramp should be able to support the weight of wheelchairs and other mobility devices.

7. **Visibility**: High visibility markings can help individuals with visual impairments navigate the ramp safely.

Manufacturers often design cable ramps with these ADA guidelines in mind, but it is essential to verify compliance for each specific product. Not all cable ramps are automatically ADA compliant, so checking the specifications and certifications is crucial.