Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electrical

- Wire Cable Management

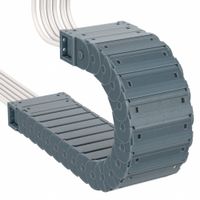

- Cable Hose Carriers

.....Read More

Frequently Asked Questions

What are cable and hose carriers used for?

Cable and hose carriers, also known as drag chains or energy chains, are used to guide and protect cables, hoses, and hydraulic or pneumatic lines in dynamic applications. They are essential in environments where these lines need to move repeatedly, ensuring that they do not become tangled, damaged, or worn out due to constant motion.

These carriers are typically made from materials like plastic or metal and are designed to withstand various environmental conditions, including exposure to chemicals, extreme temperatures, and mechanical stress. They are used in a wide range of industries, including manufacturing, robotics, automotive, and aerospace, where machinery and equipment require reliable and organized cable management systems.

In industrial automation, cable and hose carriers are crucial for maintaining the integrity and functionality of moving parts. They ensure that cables and hoses follow a predetermined path, reducing the risk of entanglement and mechanical failure. This is particularly important in applications involving robotic arms, CNC machines, and conveyor systems, where precise and repetitive movements are necessary.

Additionally, cable and hose carriers help extend the lifespan of cables and hoses by preventing abrasion and reducing the stress caused by bending and twisting. They also contribute to workplace safety by minimizing the risk of accidents related to loose or damaged cables.

Overall, cable and hose carriers are vital components in ensuring the efficient and safe operation of machinery and equipment that require dynamic cable management solutions.

How do you install cable and hose carriers?

To install cable and hose carriers, follow these steps:

1. **Select the Carrier**: Choose a carrier that suits the application, considering factors like load, environment, and movement type.

2. **Prepare the Installation Area**: Ensure the installation path is clear of obstructions and has adequate space for the carrier's movement.

3. **Measure and Cut**: Measure the required length of the carrier. Cut the carrier to size if necessary, using appropriate tools to ensure clean edges.

4. **Install Mounting Brackets**: Securely attach mounting brackets at both ends of the carrier path. Ensure they are aligned and level to prevent twisting or binding.

5. **Attach the Carrier**: Connect the carrier to the mounting brackets. For fixed end brackets, ensure they are securely fastened to prevent movement.

6. **Lay Cables and Hoses**: Carefully lay cables and hoses inside the carrier. Ensure they are not twisted or kinked. Maintain a minimum bend radius to prevent damage.

7. **Secure Cables and Hoses**: Use separators or strain relief devices to organize and secure cables and hoses within the carrier, preventing tangling and wear.

8. **Test Movement**: Manually move the carrier through its full range of motion to ensure smooth operation and check for any obstructions or binding.

9. **Adjust and Secure**: Make any necessary adjustments to the carrier or cables. Tighten all fasteners and ensure the system is secure.

10. **Final Inspection**: Conduct a final inspection to ensure all components are properly installed and functioning. Check for proper alignment and secure connections.

11. **Regular Maintenance**: Schedule regular inspections and maintenance to ensure the carrier system remains in good working condition, addressing any wear or damage promptly.

What materials are cable and hose carriers made from?

Cable and hose carriers, also known as drag chains or energy chains, are typically made from a variety of materials, each chosen for specific properties that suit different applications. The most common materials include:

1. **Plastic/Polymer**:

- **Nylon (Polyamide)**: Known for its strength, flexibility, and resistance to wear and chemicals. It is lightweight and suitable for applications requiring high speeds and accelerations.

- **Polypropylene**: Offers good chemical resistance and is often used in environments where exposure to corrosive substances is a concern.

- **Polyethylene**: Provides excellent impact resistance and is often used in applications where durability is critical.

2. **Metal**:

- **Steel**: Offers high strength and durability, making it suitable for heavy-duty applications. It is often used in environments with high temperatures or where the carrier is exposed to heavy mechanical loads.

- **Stainless Steel**: Provides excellent corrosion resistance, making it ideal for use in harsh environments, such as marine or chemical processing industries.

- **Aluminum**: Lightweight and corrosion-resistant, aluminum carriers are used in applications where weight is a concern but some level of strength is still required.

3. **Hybrid**:

- Some cable and hose carriers are made from a combination of materials, such as plastic links with metal frames, to balance the benefits of both materials, offering strength and flexibility.

The choice of material depends on factors such as the environment in which the carrier will be used, the type of cables or hoses it will carry, the required load capacity, and the desired lifespan of the carrier. Each material offers distinct advantages and limitations, making it crucial to select the appropriate type for specific industrial applications.

How do you choose the right cable and hose carrier for your application?

To choose the right cable and hose carrier for your application, consider the following factors:

1. **Application Environment**: Assess the operating environment, including temperature, exposure to chemicals, moisture, and UV radiation. Choose materials that can withstand these conditions, such as steel for high temperatures or plastic for corrosive environments.

2. **Load Requirements**: Determine the weight and size of the cables and hoses. The carrier must support the total weight without sagging or causing excessive wear. Consider the carrier's load capacity and ensure it matches your needs.

3. **Movement Type**: Analyze the type of movement (horizontal, vertical, rotary) and the length of travel. This will influence the carrier's design, such as open or closed systems, and the need for additional support.

4. **Bend Radius**: Ensure the carrier provides an adequate bend radius to prevent damage to cables and hoses. The bend radius should be larger than the minimum bend radius of the cables and hoses.

5. **Speed and Acceleration**: Consider the speed and acceleration of the application. High-speed applications may require carriers with low friction and noise-reducing features.

6. **Installation Space**: Evaluate the available space for installation. Choose a carrier that fits within the spatial constraints while allowing for easy maintenance and access.

7. **Durability and Maintenance**: Opt for carriers with a long service life and minimal maintenance requirements. Consider features like easy access for inspection and replacement of cables and hoses.

8. **Cost**: Balance the initial cost with the long-term benefits. A higher upfront investment in a quality carrier can reduce downtime and maintenance costs.

9. **Customization**: If standard options do not meet your needs, consider custom solutions tailored to your specific application requirements.

What are the benefits of using enclosed cable and hose carriers?

Enclosed cable and hose carriers offer several benefits that enhance the performance and longevity of machinery and equipment. Firstly, they provide superior protection for cables and hoses against external elements such as dust, dirt, debris, and moisture, which can cause wear and tear or even failure. This protection is crucial in harsh environments, such as manufacturing plants or outdoor applications, where exposure to contaminants is high.

Secondly, enclosed carriers help in organizing and managing cables and hoses, preventing tangling and abrasion. This organization reduces the risk of mechanical failure due to cable or hose damage, ensuring smooth and uninterrupted operation of machinery. It also simplifies maintenance and inspection processes, as the cables and hoses are neatly contained and easily accessible.

Another significant benefit is the reduction of noise and vibration. Enclosed carriers can dampen the noise generated by moving cables and hoses, contributing to a quieter working environment. This noise reduction is particularly beneficial in settings where noise pollution is a concern.

Enclosed cable and hose carriers also enhance safety by preventing accidental contact with moving parts. This containment reduces the risk of workplace accidents and injuries, promoting a safer working environment.

Moreover, these carriers can extend the lifespan of cables and hoses by protecting them from mechanical stress and environmental factors. This longevity translates to cost savings, as it reduces the frequency of replacements and repairs.

Finally, enclosed carriers can improve the aesthetic appeal of machinery by concealing cables and hoses, resulting in a cleaner and more professional appearance. This is particularly important in industries where equipment presentation is a factor, such as in exhibitions or customer-facing operations.

How do you maintain cable and hose carriers?

To maintain cable and hose carriers effectively, follow these steps:

1. **Regular Inspection**: Conduct routine visual inspections to check for wear, damage, or misalignment. Look for signs of abrasion, cracking, or deformation in the carriers and cables/hoses.

2. **Cleaning**: Keep the carriers clean from dust, debris, and any foreign materials that could cause abrasion or hinder movement. Use compressed air or a soft brush for cleaning.

3. **Lubrication**: If the carrier system requires lubrication, apply the appropriate lubricant to the moving parts to reduce friction and wear. Ensure that the lubricant is compatible with the materials of the carrier and cables/hoses.

4. **Tension and Alignment**: Ensure that the cables and hoses are properly tensioned and aligned within the carrier. They should not be too tight or too loose, as this can cause excessive wear or operational issues.

5. **Check for Obstructions**: Ensure that the carrier path is free from obstructions that could impede movement or cause damage.

6. **Replacement of Worn Parts**: Replace any worn or damaged components immediately to prevent further damage or system failure. This includes links, brackets, or any other parts showing significant wear.

7. **Monitor Load Capacity**: Ensure that the carrier is not overloaded beyond its specified capacity, as this can lead to premature wear or failure.

8. **Temperature and Environmental Considerations**: Ensure that the carrier system is suitable for the operating environment, including temperature, humidity, and exposure to chemicals or UV light.

9. **Documentation and Record Keeping**: Maintain records of inspections, maintenance activities, and any replacements or repairs performed. This helps in tracking the system's condition and planning future maintenance.

10. **Training**: Ensure that personnel involved in maintenance are properly trained and aware of the manufacturer's guidelines and best practices for maintaining cable and hose carriers.

What are the differences between standard and heavy-duty cable and hose carriers?

Standard cable and hose carriers are designed for general-purpose applications where moderate loads and speeds are involved. They are typically made from materials like plastic or lightweight metals, which provide sufficient protection and flexibility for cables and hoses in less demanding environments. These carriers are suitable for applications with limited space and where the movement is not continuous or highly repetitive. They offer ease of installation and maintenance, making them ideal for use in industries like automation, robotics, and light machinery.

Heavy-duty cable and hose carriers, on the other hand, are engineered to withstand more rigorous conditions. They are constructed from robust materials such as reinforced steel or high-strength polymers, providing enhanced durability and resistance to wear and tear. These carriers are designed to handle larger, heavier cables and hoses, and are capable of operating under high speeds and continuous motion. They are often used in harsh environments, such as in mining, construction, or heavy manufacturing, where exposure to extreme temperatures, chemicals, or abrasive materials is common. Heavy-duty carriers also offer greater load-bearing capacity and are built to endure longer service life with minimal maintenance.

In summary, the primary differences between standard and heavy-duty cable and hose carriers lie in their material composition, load capacity, durability, and suitability for different environmental conditions. Standard carriers are best for lighter, less demanding applications, while heavy-duty carriers are essential for challenging environments requiring robust performance and longevity.