Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

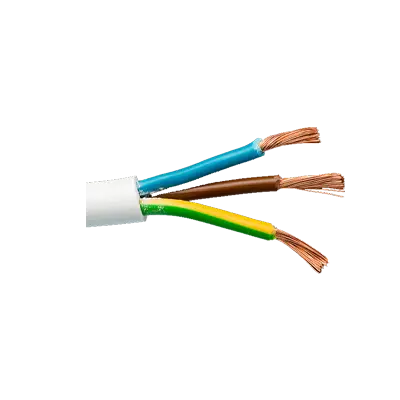

- Electrical

- Cables Conductors

- Copper Cables

.....Read More

Frequently Asked Questions

What are the advantages of using copper cables over other materials?

Copper cables offer several advantages over other materials:

1. **Electrical Conductivity**: Copper has excellent electrical conductivity, second only to silver, making it highly efficient for transmitting electricity with minimal energy loss.

2. **Ductility and Malleability**: Copper is highly ductile and malleable, allowing it to be easily drawn into thin wires and bent into various shapes without breaking, which is ideal for complex wiring systems.

3. **Thermal Conductivity**: Copper's high thermal conductivity helps in dissipating heat effectively, reducing the risk of overheating in electrical systems.

4. **Corrosion Resistance**: Copper naturally resists corrosion, which enhances the longevity and reliability of copper cables, especially in harsh environments.

5. **Tensile Strength**: Copper has a good tensile strength, providing durability and resistance to stretching, which is crucial for maintaining the integrity of cables over long distances.

6. **Compatibility**: Copper is compatible with a wide range of connectors and devices, making it versatile for various applications in telecommunications, power distribution, and electronics.

7. **Cost-Effectiveness**: While not the cheapest material, copper offers a good balance of performance and cost, making it a cost-effective choice for many applications.

8. **Recyclability**: Copper is 100% recyclable without loss of properties, making it an environmentally friendly option that supports sustainable practices.

9. **Reliability**: Copper cables are known for their reliability and consistent performance, which is critical in applications where downtime can be costly or dangerous.

10. **Established Infrastructure**: The widespread use of copper has led to a well-established infrastructure for its production, installation, and maintenance, ensuring availability and support.

These advantages make copper cables a preferred choice in many industries, including electrical, telecommunications, and construction.

How do copper cables compare to fiber optic cables?

Copper cables and fiber optic cables are two primary types of cables used for data transmission, each with distinct characteristics.

**Transmission Speed and Bandwidth**: Fiber optic cables offer significantly higher bandwidth and faster data transmission speeds compared to copper cables. Fiber optics can support speeds up to several terabits per second, while copper cables are generally limited to gigabit speeds.

**Distance**: Fiber optic cables can transmit data over much longer distances without signal degradation. They can maintain signal integrity over tens of kilometers, whereas copper cables typically experience signal loss beyond 100 meters.

**Interference**: Fiber optic cables are immune to electromagnetic interference (EMI) because they transmit data as light rather than electrical signals. Copper cables, on the other hand, are susceptible to EMI, which can affect performance, especially in environments with high electrical noise.

**Security**: Fiber optic cables provide better security as they are difficult to tap without being detected. Copper cables can be more easily tapped, posing a higher risk of data breaches.

**Durability and Reliability**: Fiber optics are generally more durable and reliable, especially in harsh environmental conditions. Copper cables can be affected by temperature fluctuations and moisture, which can degrade performance over time.

**Cost**: Copper cables are typically less expensive to purchase and install than fiber optic cables. However, the cost of fiber optics has been decreasing, and their long-term benefits often outweigh the initial investment.

**Installation and Maintenance**: Copper cables are easier to install and maintain due to their flexibility and robustness. Fiber optics require more careful handling and specialized equipment for installation and repairs.

In summary, fiber optic cables are superior in terms of speed, distance, and reliability, while copper cables are more cost-effective and easier to handle for shorter distances and less demanding applications.

What are the different types of copper cables available?

There are several types of copper cables, each designed for specific applications and environments:

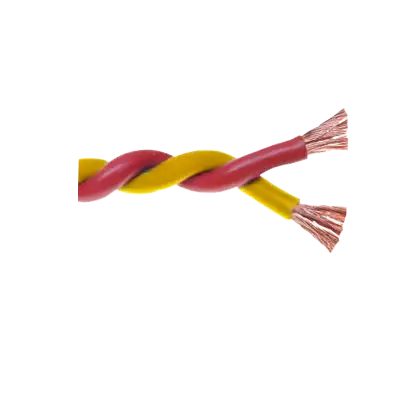

1. **Twisted Pair Cable**:

- **Unshielded Twisted Pair (UTP)**: Commonly used in Ethernet networks, telephone systems, and LANs. It consists of pairs of wires twisted together to reduce electromagnetic interference.

- **Shielded Twisted Pair (STP)**: Similar to UTP but includes a shielding to provide better protection against interference, used in environments with high electromagnetic interference.

2. **Coaxial Cable**:

- Used for cable television, internet connections, and other data communications. It consists of a central conductor, insulating layer, metallic shield, and outer insulating layer, providing good protection against interference.

3. **Multi-Conductor Cable**:

- Contains multiple insulated conductors within a single cable jacket. Used in control systems, audio applications, and instrumentation.

4. **Ribbon Cable**:

- Consists of multiple conducting wires running parallel to each other on the same flat plane. Commonly used in internal computer connections and electronic devices.

5. **Direct Burial Cable**:

- Designed for underground installation without additional conduit. It is water-resistant and durable, used for outdoor and underground applications.

6. **Plenum Cable**:

- Used in building spaces for air circulation, such as ceilings and floors. It has a fire-retardant jacket to prevent the spread of flames.

7. **Patch Cable**:

- Short cables used to connect devices to a network, typically in data centers and telecommunications rooms.

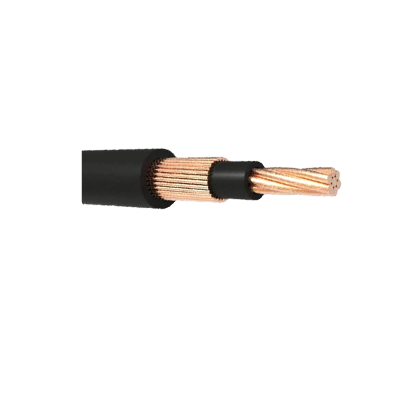

8. **Power Cable**:

- Used to transmit electrical power, available in various configurations for different voltage and current requirements.

Each type of copper cable is selected based on factors like data transmission requirements, environmental conditions, and installation needs.

How do you properly install copper cables?

1. **Planning and Design**: Assess the installation site and create a detailed plan. Determine the cable type, length, and pathway, considering factors like electrical load, environmental conditions, and future scalability.

2. **Safety Precautions**: Ensure all safety protocols are in place. De-energize circuits, wear appropriate personal protective equipment (PPE), and use insulated tools.

3. **Material Preparation**: Gather necessary materials and tools, including copper cables, connectors, cable ties, conduit, and labeling materials.

4. **Cable Pathway Preparation**: Clear the pathway of obstructions. Install conduits or cable trays if required, ensuring they are securely mounted and provide adequate support.

5. **Cable Measurement and Cutting**: Measure the required length of the cable, allowing extra for connections and potential future adjustments. Cut the cable cleanly using appropriate tools.

6. **Cable Pulling**: Use a cable puller or fish tape to guide the cable through conduits or along trays. Avoid excessive force to prevent damage. Use lubricant if necessary to ease the pulling process.

7. **Cable Securing**: Secure the cable at regular intervals using cable ties or clamps. Ensure the cable is not under tension and has some slack to accommodate movement and thermal expansion.

8. **Termination and Connection**: Strip the cable ends carefully to expose the conductors. Use appropriate connectors or terminals to attach the cable to devices or junction boxes. Ensure connections are tight and secure.

9. **Testing and Verification**: Test the installation for continuity, insulation resistance, and proper grounding. Use a multimeter or cable tester to verify connections and ensure compliance with electrical standards.

10. **Labeling and Documentation**: Label cables clearly at both ends and at key points along the pathway. Document the installation details, including cable routes, connections, and test results for future reference.

11. **Final Inspection**: Conduct a thorough inspection to ensure compliance with safety standards and installation guidelines. Make any necessary adjustments before energizing the system.

What is the lifespan of copper cables in electrical systems?

The lifespan of copper cables in electrical systems typically ranges from 20 to 50 years, depending on several factors. These factors include the quality of the copper used, the environmental conditions, the installation process, and the level of maintenance provided.

High-quality copper cables, when installed correctly and maintained properly, can last up to 50 years or more. The purity of the copper and the quality of the insulation material play crucial roles in determining the cable's longevity. Insulation protects the copper from environmental factors such as moisture, temperature fluctuations, and chemical exposure, which can lead to degradation over time.

Environmental conditions significantly impact the lifespan of copper cables. In harsh environments, such as those with high humidity, extreme temperatures, or exposure to corrosive substances, the lifespan may be reduced. Proper insulation and protective measures, like conduit or shielding, can mitigate these effects and extend the cable's life.

The installation process is another critical factor. Poor installation practices, such as improper bending, over-tightening, or inadequate support, can cause physical damage to the cables, leading to premature failure. Ensuring that cables are installed according to industry standards and guidelines is essential for maximizing their lifespan.

Regular maintenance and inspections are vital for prolonging the life of copper cables. Identifying and addressing issues such as insulation damage, corrosion, or loose connections early can prevent more significant problems and extend the cable's service life.

In summary, while the typical lifespan of copper cables in electrical systems is 20 to 50 years, achieving the upper end of this range requires high-quality materials, proper installation, suitable environmental conditions, and regular maintenance.

How do you maintain and troubleshoot copper cables?

To maintain and troubleshoot copper cables, follow these steps:

1. **Regular Inspection**: Conduct visual inspections to check for physical damage, corrosion, or wear. Look for signs of fraying, cuts, or exposed wires.

2. **Cleaning**: Clean connectors and cable ends to remove dust, dirt, and oxidation. Use appropriate cleaning solutions and tools to ensure good contact.

3. **Testing**: Use a cable tester to check for continuity, shorts, and open circuits. This helps identify faulty cables or connections.

4. **Signal Quality Check**: Measure signal strength and quality using a time-domain reflectometer (TDR) or a network analyzer to detect impedance mismatches or attenuation issues.

5. **Proper Installation**: Ensure cables are installed correctly, avoiding sharp bends, kinks, or excessive tension. Use cable management systems to organize and protect cables.

6. **Environmental Control**: Protect cables from extreme temperatures, moisture, and chemical exposure. Use appropriate insulation and shielding to prevent interference.

7. **Documentation**: Keep detailed records of cable layouts, test results, and maintenance activities to aid in future troubleshooting and maintenance.

8. **Repair and Replacement**: Repair minor damages with appropriate tools and materials. Replace severely damaged or degraded cables to maintain network integrity.

9. **Grounding and Bonding**: Ensure proper grounding and bonding to prevent electrical interference and enhance safety.

10. **Training and Safety**: Train personnel in proper handling and safety procedures to prevent accidents and damage during maintenance.

By following these steps, you can effectively maintain and troubleshoot copper cables, ensuring reliable performance and longevity.

What are the environmental impacts of using copper cables?

The environmental impacts of using copper cables are multifaceted, spanning from extraction to disposal.

1. **Mining and Extraction**: Copper mining is energy-intensive and often involves open-pit mining, which leads to habitat destruction, deforestation, and soil erosion. The process generates significant amounts of waste rock and tailings, which can leach harmful chemicals into the environment, contaminating soil and water sources. The use of sulfuric acid in copper extraction can lead to acid mine drainage, further polluting water bodies.

2. **Energy Consumption**: The extraction and processing of copper require substantial energy, contributing to greenhouse gas emissions. The smelting and refining processes are particularly energy-intensive, often relying on fossil fuels, which exacerbate climate change.

3. **Water Usage and Pollution**: Copper mining and processing consume large quantities of water, which can lead to water scarcity in surrounding areas. The discharge of contaminated water from mining operations can introduce heavy metals and toxic substances into local water systems, affecting aquatic life and human health.

4. **Air Pollution**: The smelting process releases sulfur dioxide and other pollutants into the atmosphere, contributing to air pollution and acid rain. These emissions can harm ecosystems, corrode buildings, and pose health risks to humans.

5. **Waste Generation**: Copper cable production generates waste, including slag and other by-products, which require proper disposal to prevent environmental contamination. Improper disposal can lead to soil and water pollution.

6. **Recycling and Disposal**: While copper is highly recyclable, improper disposal of copper cables can lead to environmental harm. Recycling processes, if not managed correctly, can also release pollutants. However, recycling copper reduces the need for new mining and conserves natural resources.

Overall, while copper cables are essential for modern infrastructure, their environmental impacts necessitate sustainable practices in mining, production, and recycling to mitigate harm.