Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Welding

- Weld Fixturing Marking Preparation

- Pipe Welding Layout Preparation Tools

.....Read More

Frequently Asked Questions

What are the essential tools for pipe welding layout and preparation?

Essential tools for pipe welding layout and preparation include:

1. **Measuring Tools**:

- **Tape Measure**: For accurate measurement of pipe lengths and diameters.

- **Calipers**: For precise measurement of pipe thickness and diameter.

2. **Marking Tools**:

- **Soapstone**: For marking on metal surfaces, visible even under high heat.

- **Center Punch**: To create indentations for drilling or cutting.

3. **Cutting Tools**:

- **Pipe Cutter**: For clean, straight cuts on pipes.

- **Oxy-Acetylene Torch**: For cutting thicker pipes or making bevels.

- **Angle Grinder**: For cutting, grinding, and finishing edges.

4. **Alignment Tools**:

- **Pipe Clamps**: To hold pipes in place during welding.

- **Level**: To ensure pipes are aligned correctly.

- **Flange Aligners**: For aligning flanges accurately.

5. **Beveling Tools**:

- **Beveling Machine**: For creating beveled edges on pipes for better weld penetration.

- **Hand Files**: For manual beveling and finishing.

6. **Cleaning Tools**:

- **Wire Brush**: For cleaning pipe surfaces before welding.

- **Solvent Cleaner**: To remove oil, grease, and other contaminants.

7. **Safety Equipment**:

- **Welding Helmet**: To protect eyes and face from sparks and UV radiation.

- **Gloves and Protective Clothing**: To protect against burns and heat.

8. **Layout Tools**:

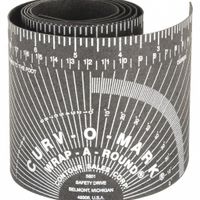

- **Pipe Wraps**: For marking straight lines around pipes.

- **Protractor**: For measuring angles accurately.

9. **Inspection Tools**:

- **Weld Gauge**: To check weld size and quality.

- **Ultrasonic Tester**: For non-destructive testing of weld integrity.

These tools ensure precision, safety, and efficiency in pipe welding projects.

How do pipe marking tools improve welding accuracy?

Pipe marking tools improve welding accuracy by providing clear, precise, and consistent guidelines for welders to follow. These tools help in several ways:

1. **Alignment and Measurement**: Pipe marking tools ensure that pipes are properly aligned before welding. They provide accurate measurements and markings, which are crucial for maintaining the correct angles and dimensions, reducing the risk of misalignment.

2. **Consistency**: By using standardized markings, these tools help maintain consistency across multiple welds. This is particularly important in large projects where uniformity is critical for structural integrity and performance.

3. **Error Reduction**: Clear markings reduce the likelihood of human error. Welders can easily follow the guidelines, minimizing mistakes that could lead to weak joints or the need for rework.

4. **Efficiency**: With precise markings, welders can work more efficiently, as they spend less time measuring and adjusting. This leads to faster project completion without compromising quality.

5. **Quality Control**: Pipe marking tools facilitate better quality control by providing a visual reference that can be easily checked against project specifications. This ensures that all welds meet the required standards.

6. **Communication**: These tools help in communicating specific instructions and details among team members, ensuring everyone is on the same page regarding the welding process.

Overall, pipe marking tools are essential for achieving high welding accuracy, improving both the quality and efficiency of welding operations.

What is the purpose of pipe measuring tools in welding?

Pipe measuring tools in welding are essential for ensuring precision, accuracy, and quality in the fabrication and assembly of piping systems. These tools serve several key purposes:

1. **Alignment and Fit-Up**: Pipe measuring tools help in aligning pipes correctly before welding. Proper alignment is crucial to ensure that the pipes fit together seamlessly, which is vital for maintaining the integrity and strength of the weld.

2. **Dimensional Accuracy**: These tools ensure that the dimensions of the pipes and the gaps between them meet the specified requirements. Accurate measurements prevent issues such as misalignment, which can lead to weak joints or structural failures.

3. **Angle Measurement**: In welding, especially when dealing with complex piping systems, it is important to measure angles accurately. Pipe measuring tools help in determining the correct angles for cuts and joints, ensuring that the pipes fit together as intended.

4. **Gap Measurement**: Maintaining the correct gap between pipes is crucial for achieving a strong weld. Pipe measuring tools help in measuring and maintaining the appropriate gap, which is essential for proper penetration and fusion of the weld.

5. **Quality Control**: By providing precise measurements, these tools play a critical role in quality control. They help in verifying that the welded joints meet industry standards and specifications, reducing the risk of defects and rework.

6. **Efficiency**: Using pipe measuring tools increases the efficiency of the welding process by reducing the time spent on adjustments and corrections. This leads to faster project completion and cost savings.

Overall, pipe measuring tools are indispensable in welding for ensuring that the final product is structurally sound, meets design specifications, and is completed efficiently.

How do pipe welding clamps work?

Pipe welding clamps are tools used to hold and align pipes during the welding process, ensuring precision and stability. They work by securing the pipes in place, preventing movement and misalignment, which can lead to poor weld quality and structural weaknesses.

The operation of pipe welding clamps involves several key components and steps:

1. **Design and Structure**: Pipe welding clamps typically consist of a frame or body, adjustable arms or jaws, and a locking mechanism. The frame provides the main support, while the arms or jaws are adjustable to accommodate different pipe sizes and shapes.

2. **Adjustment and Alignment**: The clamps are adjustable to fit various pipe diameters. The jaws or arms can be moved to align the pipes accurately. This alignment is crucial for ensuring that the weld is even and that the pipes are joined at the correct angle.

3. **Securing the Pipes**: Once the pipes are aligned, the clamp's locking mechanism is engaged. This mechanism can be a screw, lever, or cam lock, which tightens the jaws around the pipes, holding them firmly in place. This prevents any movement during the welding process.

4. **Stability During Welding**: With the pipes secured, the welder can perform the welding process without worrying about the pipes shifting. This stability is essential for achieving a high-quality weld, as even slight movements can cause defects.

5. **Ease of Use**: Pipe welding clamps are designed for ease of use, allowing for quick adjustments and secure locking. This efficiency is important in industrial settings where time and precision are critical.

Overall, pipe welding clamps are essential tools in the welding industry, providing the necessary support and alignment to ensure strong, reliable welds.

Why are socket weld spacer rings important in welding?

Socket weld spacer rings are crucial in welding for several reasons:

1. **Alignment and Gap Control**: Spacer rings ensure proper alignment and maintain a consistent gap between the pipe and the fitting. This gap is essential for accommodating thermal expansion and contraction, preventing stress concentration, and ensuring a uniform weld bead.

2. **Weld Quality**: By maintaining the correct gap, spacer rings help achieve full penetration and fusion of the weld, which is critical for the structural integrity and strength of the joint. This reduces the risk of defects such as lack of fusion or incomplete penetration.

3. **Thermal Expansion**: The gap provided by spacer rings allows for thermal expansion of the pipe during operation. This prevents excessive stress on the weld joint, reducing the likelihood of cracking or failure over time.

4. **Corrosion Prevention**: Proper spacing helps in reducing crevice corrosion by ensuring that the weld bead is continuous and smooth, minimizing areas where corrosive agents can accumulate.

5. **Ease of Inspection and Maintenance**: A well-aligned and properly spaced weld is easier to inspect for defects and maintain over time. This is particularly important in industries where safety and reliability are paramount, such as oil and gas or chemical processing.

6. **Standardization and Consistency**: Spacer rings help standardize the welding process, ensuring consistency across multiple joints. This is important for large-scale projects where uniformity in weld quality is necessary.

7. **Cost Efficiency**: By reducing the likelihood of weld defects and subsequent repairs, spacer rings contribute to cost savings in both labor and materials.

In summary, socket weld spacer rings play a vital role in ensuring the quality, durability, and reliability of welded joints, making them an essential component in many industrial applications.

What is the role of pipe purging equipment in welding?

Pipe purging equipment plays a crucial role in welding, particularly in processes involving stainless steel, titanium, and other reactive metals. The primary function of pipe purging is to create a controlled environment inside the pipe by removing oxygen and other reactive gases, which can lead to oxidation and contamination of the weld. This is achieved by introducing an inert gas, typically argon or nitrogen, into the pipe to displace the air.

The purging process begins by sealing the pipe ends with purging dams or bladders, which are inflatable devices that block the pipe's interior. Once sealed, the inert gas is introduced, reducing the oxygen level to a minimal concentration, often below 0.1%. This low-oxygen environment prevents the formation of oxides and other impurities on the weld bead and the heat-affected zone, ensuring a clean, high-quality weld.

Effective pipe purging is essential for achieving optimal mechanical properties and corrosion resistance in the welded joint. It helps in maintaining the desired metallurgical characteristics of the base material and the filler metal. Additionally, purging minimizes the risk of weld defects such as porosity, discoloration, and lack of fusion, which can compromise the integrity and longevity of the weld.

In summary, pipe purging equipment is vital for ensuring the quality and durability of welds in critical applications. It provides a protective atmosphere that prevents contamination, enhances the aesthetic appearance of the weld, and ensures compliance with industry standards and specifications.

How can I ensure repeatable welds in pipe welding?

To ensure repeatable welds in pipe welding, follow these key practices:

1. **Material Preparation**: Clean the pipe surfaces thoroughly to remove any rust, oil, or contaminants. Ensure proper fit-up and alignment to avoid gaps or misalignment.

2. **Consistent Welding Procedure**: Develop and adhere to a Welding Procedure Specification (WPS) that outlines parameters such as voltage, amperage, travel speed, and electrode type. This ensures consistency across all welds.

3. **Skilled Workforce**: Employ certified and experienced welders who are familiar with the specific welding process and materials. Regular training and certification updates are crucial.

4. **Quality Equipment**: Use high-quality welding machines and tools that are regularly maintained and calibrated. This minimizes equipment-related variability.

5. **Environmental Control**: Control environmental factors such as wind, temperature, and humidity, which can affect weld quality. Use windshields or tents if necessary.

6. **Preheat and Interpass Temperature**: Maintain appropriate preheat and interpass temperatures to prevent cracking and ensure proper fusion. Use temperature sticks or infrared thermometers for accuracy.

7. **Weld Monitoring**: Implement real-time monitoring systems to track welding parameters and ensure they remain within specified limits. This helps in identifying deviations immediately.

8. **Non-Destructive Testing (NDT)**: Conduct regular NDT such as radiographic or ultrasonic testing to detect defects. This ensures that any issues are identified and rectified promptly.

9. **Documentation and Feedback**: Keep detailed records of welding parameters, materials, and inspection results. Use this data for continuous improvement and troubleshooting.

10. **Post-Weld Heat Treatment (PWHT)**: Apply PWHT if required to relieve residual stresses and improve weld properties.

By integrating these practices, you can achieve consistent, high-quality welds in pipe welding applications.