Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Tools

- Hand Tools

- Files

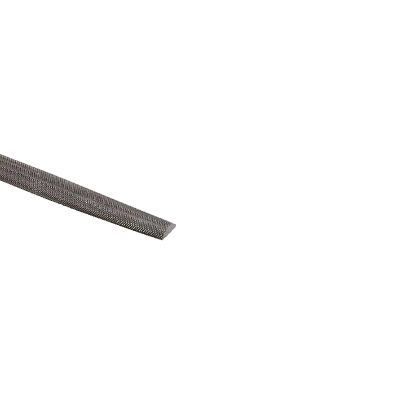

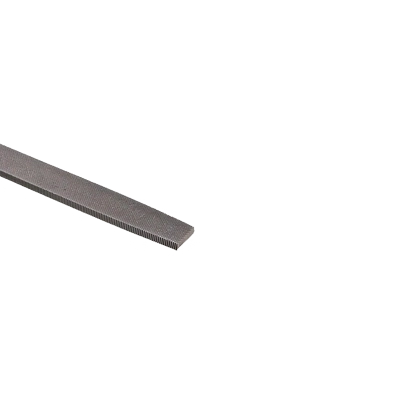

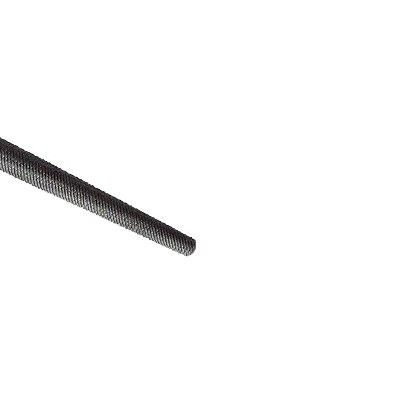

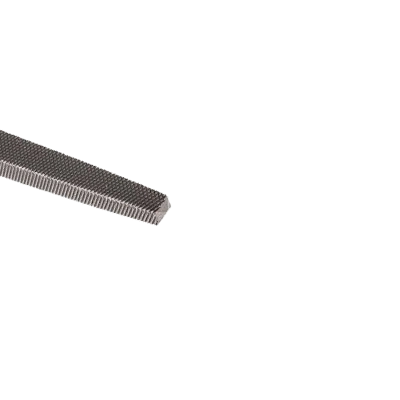

- Material Removing American Pattern Files

.....Read More

Frequently Asked Questions

What are American-pattern files used for?

American-pattern files are versatile hand tools used for shaping, smoothing, and finishing materials such as metal, wood, and plastic. They are characterized by their distinct tooth patterns and are available in various shapes and sizes to suit different applications.

1. **Metalworking**: In metalworking, American-pattern files are used to remove burrs, smooth rough edges, and refine the surface of metal parts. They are essential for fitting and finishing tasks, ensuring that components fit together precisely.

2. **Woodworking**: Woodworkers use these files to shape and smooth wooden surfaces, especially in detailed work where precision is required. They help in refining joints, shaping curves, and achieving a smooth finish on wood projects.

3. **Plastic Shaping**: For plastic materials, American-pattern files are used to deburr edges, smooth surfaces, and shape components to the desired form. They are particularly useful in prototyping and custom fabrication.

4. **Tool and Die Making**: In tool and die making, these files are used for fine-tuning and finishing dies and molds. They help achieve the necessary precision and surface finish required in high-quality tool production.

5. **General Maintenance and Repair**: American-pattern files are also used in general maintenance and repair tasks, such as sharpening blades, cleaning up threads, and refurbishing tools. They are a staple in many toolkits for their ability to perform a wide range of tasks.

Overall, American-pattern files are essential tools in various industries and crafts, valued for their ability to provide precise control and a high-quality finish on a variety of materials.

How do American-pattern files differ from Swiss-pattern files?

American-pattern files and Swiss-pattern files differ primarily in their design, precision, and intended use:

1. **Design and Shape**:

- **American-Pattern Files**: These files are generally larger and heavier, designed for more aggressive material removal. They come in a variety of shapes such as flat, half-round, round, and triangular.

- **Swiss-Pattern Files**: These are smaller, more delicate, and designed for precision work. They are often used in fine metalworking, jewelry making, and watchmaking.

2. **Cut and Teeth**:

- **American-Pattern Files**: They have coarser teeth and are available in three main cuts: bastard, second cut, and smooth. The teeth are designed for rapid material removal and are less precise.

- **Swiss-Pattern Files**: These files have finer teeth and are available in a wider range of cuts, often numbered from 00 (coarse) to 6 (very fine). They provide a smoother finish and greater precision.

3. **Precision and Finish**:

- **American-Pattern Files**: Used for general-purpose filing where precision is not the primary concern. They are suitable for tasks like sharpening tools or removing large amounts of material.

- **Swiss-Pattern Files**: Known for their precision and ability to produce a fine finish. They are ideal for detailed work requiring accuracy and smoothness.

4. **Applications**:

- **American-Pattern Files**: Commonly used in woodworking, metalworking, and general maintenance tasks.

- **Swiss-Pattern Files**: Preferred in industries requiring high precision, such as jewelry making, watchmaking, and fine metalworking.

5. **Manufacturing Standards**:

- **American-Pattern Files**: Typically manufactured to less stringent standards compared to Swiss-pattern files.

- **Swiss-Pattern Files**: Manufactured to high standards, ensuring uniformity and precision.

In summary, American-pattern files are suited for rough, general-purpose work, while Swiss-pattern files are designed for precision and fine finishing.

What types of materials can American-pattern files work on?

American-pattern files are versatile tools used for shaping, smoothing, and finishing a variety of materials. They are commonly employed on:

1. **Metals**: These files are effective on a range of metals, including steel, iron, aluminum, brass, and copper. They are used for deburring, smoothing edges, and refining metal surfaces.

2. **Wood**: American-pattern files can be used on wood for shaping and smoothing. They are particularly useful in woodworking for refining edges and creating intricate details.

3. **Plastics**: These files can work on various types of plastics, helping to smooth edges and remove excess material. They are often used in model-making and plastic fabrication.

4. **Composites**: American-pattern files can be used on composite materials, such as fiberglass and carbon fiber, to shape and finish surfaces.

5. **Soft Materials**: They are also suitable for softer materials like leather and rubber, allowing for precise shaping and finishing.

These files come in different shapes and cuts, making them adaptable for various applications across these materials.

How do you choose the right file for metal workpieces?

To choose the right file for metal workpieces, consider the following factors:

1. **Material Type**: Match the file material to the workpiece. Use high-carbon steel files for general metalwork, while tungsten carbide files are suitable for harder metals.

2. **File Shape**: Select the shape based on the workpiece's contours. Flat files are ideal for flat surfaces, round files for circular openings, half-round files for curved surfaces, and triangular files for corners and angles.

3. **File Cut**: Choose the cut based on the desired finish. Single-cut files are for smooth finishes and light removal, while double-cut files are for faster material removal and rougher finishes. Rasp-cut files are for soft metals.

4. **File Size**: Consider the file length and width. Larger files remove more material and are suitable for larger workpieces, while smaller files offer precision for detailed work.

5. **Teeth Per Inch (TPI)**: Higher TPI provides a finer finish, suitable for delicate work, while lower TPI is for aggressive material removal.

6. **Handle Comfort**: Ensure the file has a comfortable handle for better control and reduced fatigue during prolonged use.

7. **Specialty Files**: For specific tasks, use specialty files like needle files for intricate work, or diamond files for hard materials.

8. **Quality and Brand**: Opt for reputable brands known for durability and performance to ensure longevity and efficiency.

By considering these factors, you can select the appropriate file that meets the specific requirements of your metalworking project, ensuring efficiency and precision.

What is the best file for working with aluminum?

The best file for working with aluminum is a single-cut, flat, or half-round file made from high-carbon steel. Aluminum is a soft metal, so a single-cut file is ideal as it has a single set of parallel teeth that provide a smooth finish and prevent clogging. A flat file is versatile for general shaping and smoothing, while a half-round file is useful for both flat and curved surfaces.

To prevent clogging, which is common with aluminum, use a file with coarser teeth and apply chalk or a file card to the file before use. This helps to reduce the buildup of aluminum particles. Additionally, a bastard cut file, which has medium coarseness, is often recommended for initial shaping, while a second cut or smooth file can be used for finer finishing.

For intricate work or detailed shaping, needle files or rifflers can be used. These are smaller and allow for precision in tight spaces or on detailed workpieces.

Overall, the choice of file depends on the specific task, but a high-quality, single-cut, flat or half-round file with proper maintenance will provide the best results when working with aluminum.

How do you maintain and clean American-pattern files?

To maintain and clean American-pattern files, follow these steps:

1. **Regular Cleaning**: After each use, brush the file with a file card or wire brush to remove filings and debris. This prevents clogging and maintains the file's cutting efficiency.

2. **Avoid Moisture**: Store files in a dry environment to prevent rust. If a file gets wet, dry it immediately and apply a light coat of oil to protect against corrosion.

3. **Proper Storage**: Store files in a tool rack or wrap them in a cloth to prevent them from knocking against each other, which can dull the teeth. Ensure they are not in contact with other tools.

4. **Use Correctly**: Always use the file in the correct direction, typically with a forward stroke, to prevent damage to the teeth. Avoid applying excessive pressure, which can wear out the file prematurely.

5. **Sharpening**: If a file becomes dull, it can be sharpened using a file sharpening solution or by sending it to a professional service. However, this is often not cost-effective for inexpensive files.

6. **Avoid Contamination**: Keep files away from materials that can clog the teeth, such as soft metals or plastics, unless specifically designed for those materials.

7. **Inspect Regularly**: Check files for wear and damage. Replace files that are excessively worn or have broken teeth, as they can damage workpieces and reduce efficiency.

8. **Use the Right File**: Ensure you are using the correct type and size of file for the task to prevent unnecessary wear and maintain effectiveness.

By following these practices, you can extend the life of your American-pattern files and ensure they remain effective for precision work.

Can American-pattern files be used on wood?

Yes, American-pattern files can be used on wood, but with some considerations. These files are typically designed for metalworking and have a coarser cut compared to files specifically made for woodworking. When using them on wood, they can be effective for shaping, smoothing, or removing material quickly, especially on harder woods. However, due to their aggressive cutting action, they may leave a rougher finish than files designed for wood, such as rasps or cabinet files.

To achieve a smoother finish, it is advisable to follow up with finer tools or sandpaper after using an American-pattern file. Additionally, care should be taken to ensure that the file is clean and free of metal filings before use on wood to prevent contamination or damage to the wood surface.

In summary, while American-pattern files can be used on wood, they are best suited for rough shaping or initial material removal. For finer work or a smoother finish, tools specifically designed for woodworking are recommended.