- Home

- Pipe Hose Tube Fittings

- Pipe Pipe Fittings

- Pipe Fitting Gaskets

- Flange Gaskets

.....Read More

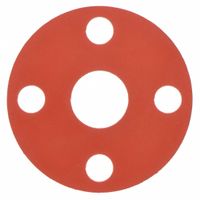

Abrasion-Resistant SBR Flange Gaskets

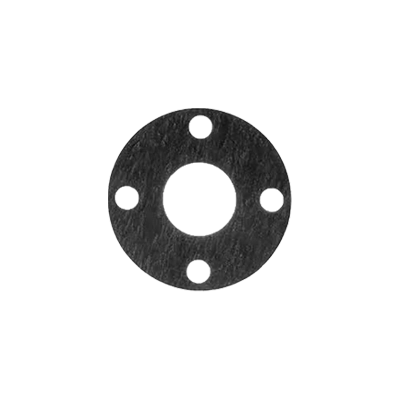

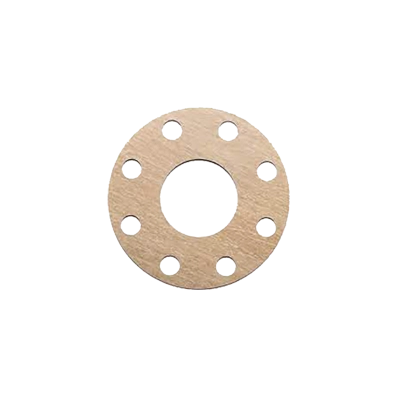

Aramid Gaskets with Abrasion-Resistant SBR Binder

Aramid Gaskets with Oil-Resistant Buna-N Binder

Aramid Gaskets with Steam-Resistant EPDM Binder

Aramid Gaskets with Water-Resistant Neoprene Binder

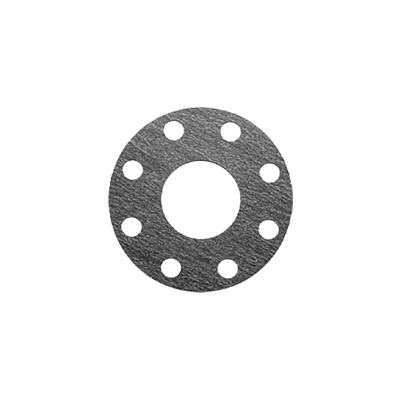

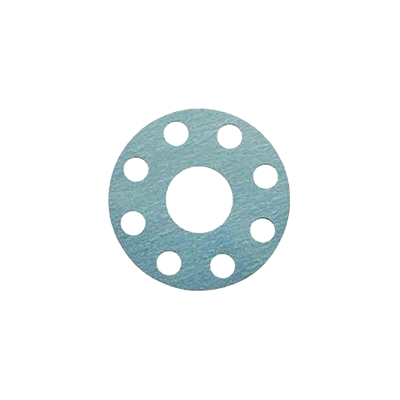

Chemical & Oil-Resistant Viton Flange Gaskets

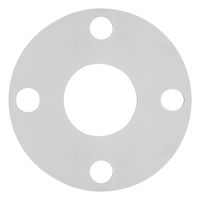

Chemical-Resistant PTFE Flange Gaskets

Extreme-Temperature Metallic Flange Gaskets

High-Temperature Graphite Flange Gaskets

High-Temperature Silicone Flange Gaskets

Oil-Resistant Buna-N Flange Gaskets

Steam-Resistant EPDM Flange Gaskets

Water-Resistant Neoprene Flange Gaskets

Frequently Asked Questions

What are flange gaskets used for?

What materials are flange gaskets made from?

How do I choose the right flange gasket for my application?

What are the different types of flange gaskets?

How do flange gaskets prevent leaks?

What are the benefits of using flange gaskets?

How do I install a flange gasket correctly?