- Home

- Material Handling

- Transporting

- Conveyors Components

.....Read More

Ball Transfer Conveyors & Components

Belt Conveyors & Components

Conveyor Brushes

Conveyor Guides

Conveyor Netting

Conveyor Support Stands & Connecting Hardware

Magnetic Separators

Material Flow Racks & Rails

Material Support & Transfer Stands

Overhead Conveyor Components

Roller Conveyors & Components

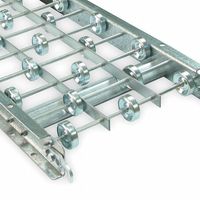

Skate Wheel Conveyors & Components

Vacuum Conveyors

Vibratory Feeders

Frequently Asked Questions

What are the different types of conveyors used in industrial applications?

How do skate wheel conveyors work and what are their advantages?

What are the benefits of using roller conveyors for heavy loads?

How do ball transfer conveyors facilitate multi-directional movement?

What are the key features of belt conveyors for handling fragile items?

How do conveyor support stands and hardware enhance conveyor systems?

What factors should be considered when choosing a conveyor system for a specific application?