Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

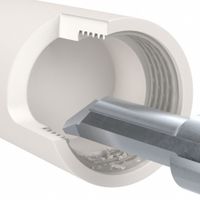

- Machining

- Turning Boring Grooving

- Internal Threading Tools Sets

.....Read More

Frequently Asked Questions

What are internal threading tools used for?

Internal threading tools are used to create threads on the inside surface of a hole, allowing a fastener such as a bolt or screw to be securely inserted. These tools are essential in manufacturing and repair processes where precise and durable internal threads are required. They are commonly used in industries such as automotive, aerospace, machinery, and construction.

The primary types of internal threading tools include taps, thread mills, and single-point threading tools. Taps are the most common and are designed to cut threads by removing material from the inside of a pre-drilled hole. They come in various forms, such as hand taps, spiral point taps, and spiral flute taps, each suited for different materials and applications.

Thread mills, on the other hand, are used in CNC machines to create threads by milling rather than cutting. They offer greater flexibility, allowing for the creation of threads of varying sizes and pitches with a single tool. This method is particularly useful for producing threads in hard materials or when high precision is required.

Single-point threading tools are used in lathes and CNC machines to cut threads by tracing the desired thread profile. This method is ideal for creating custom threads or when working with large diameters.

Internal threading tools are crucial for ensuring the integrity and functionality of threaded connections. They must be chosen based on the material being threaded, the size and type of thread required, and the specific application to ensure optimal performance and longevity of the threads. Proper use and maintenance of these tools are essential to achieve accurate and reliable threading results.

How do internal threading tools work?

Internal threading tools are designed to create threads inside a pre-drilled hole, allowing for the insertion of screws or bolts. These tools typically include taps, which are the most common type of internal threading tool. Taps are made from high-speed steel or carbide and come in various types, such as hand taps, machine taps, and spiral point taps, each suited for different materials and applications.

The process begins with selecting the appropriate tap size, which corresponds to the desired thread size and pitch. The hole is drilled slightly smaller than the tap's major diameter to ensure proper thread engagement. The tap is then aligned with the hole to ensure perpendicular entry, which is crucial for accurate threading.

As the tap is rotated, its cutting edges remove material from the hole's interior, forming the thread profile. The flutes on the tap serve dual purposes: they provide cutting edges and allow chips to escape, preventing clogging and ensuring a smooth threading process. Lubrication is often applied to reduce friction and heat, prolonging the tool's life and improving the finish of the threads.

For manual tapping, a tap wrench is used to apply even pressure and control the rotation. In machine tapping, the tap is mounted on a tapping head or a CNC machine, which provides consistent speed and feed rates, enhancing precision and efficiency.

After threading, the hole is cleaned to remove any debris or chips. The newly formed threads are then ready to accommodate fasteners, providing secure and reliable connections in various applications, from automotive to aerospace industries.

What materials can internal threading tools cut?

Internal threading tools are designed to cut threads on the inside of a hole or cylindrical surface. These tools can cut a variety of materials, including:

1. **Steel**: Internal threading tools can cut various types of steel, including carbon steel, alloy steel, and stainless steel. These materials are commonly used in industrial applications due to their strength and durability.

2. **Aluminum**: Aluminum is a lightweight, non-ferrous metal that is easy to machine. Internal threading tools can efficiently cut threads in aluminum, which is often used in automotive and aerospace industries.

3. **Brass**: Known for its machinability, brass is a copper-zinc alloy that is often used in plumbing and electrical applications. Internal threading tools can create precise threads in brass components.

4. **Copper**: Copper is a ductile metal with excellent electrical conductivity. Internal threading tools can cut threads in copper, which is frequently used in electrical and plumbing applications.

5. **Titanium**: Although more challenging to machine due to its strength and tendency to work harden, internal threading tools can cut threads in titanium, which is used in aerospace, medical, and high-performance applications.

6. **Plastics**: Internal threading tools can also cut threads in various plastics, such as nylon, PVC, and acrylic. These materials are used in a wide range of applications, from consumer products to industrial components.

7. **Cast Iron**: Known for its brittleness, cast iron can still be threaded using internal threading tools, which are often used in automotive and machinery components.

8. **Inconel and Other Superalloys**: These high-performance materials are used in extreme environments. Internal threading tools with specialized coatings and geometries can cut threads in these challenging materials.

The choice of tool material, coating, and geometry is crucial for effectively cutting threads in these diverse materials.

What are the different types of internal threading tools?

Internal threading tools are essential for creating threads inside holes or cylindrical objects. The main types include:

1. **Taps**: These are the most common tools for internal threading. They come in various types:

- **Hand Taps**: Typically used in sets of three (taper, plug, and bottoming) for manual threading.

- **Machine Taps**: Designed for use with machines, offering higher precision and speed.

- **Spiral Point Taps**: Ideal for through holes, as they push chips forward.

- **Spiral Flute Taps**: Suitable for blind holes, as they pull chips back out of the hole.

- **Forming Taps**: Create threads by deforming the material rather than cutting, resulting in stronger threads.

2. **Thread Mills**: These are versatile tools used in CNC machines to cut internal threads. They can create threads of different sizes with the same tool and are ideal for high-precision applications.

3. **Single-Point Threading Tools**: Used in lathes, these tools cut threads one at a time. They are highly versatile and can be used for both internal and external threading.

4. **Internal Threading Inserts**: These are replaceable cutting edges used in boring bars for CNC machines. They offer precision and are suitable for high-volume production.

5. **Boring Bars**: Equipped with internal threading inserts, these tools are used in lathes and CNC machines to cut internal threads.

6. **Thread Gages**: While not cutting tools, they are essential for measuring and ensuring the accuracy of internal threads.

Each type of tool is chosen based on the material, thread size, hole depth, and production volume requirements.

How do you choose the right internal threading tool?

To choose the right internal threading tool, consider the following factors:

1. **Thread Type and Size**: Identify the thread type (e.g., metric, UNC, UNF) and size you need. This determines the tool's specifications, such as diameter and pitch.

2. **Material**: Consider the material of the workpiece. Different materials require specific tool materials and coatings for optimal performance. For example, carbide tools are suitable for hard materials, while high-speed steel (HSS) may be used for softer materials.

3. **Tool Material and Coating**: Select the tool material based on the workpiece material. Coatings like TiN, TiCN, or TiAlN can enhance tool life and performance by reducing friction and wear.

4. **Machine Type**: Ensure compatibility with the machine (e.g., CNC lathe, manual lathe). The tool should fit the machine's tool holder and be suitable for the machine's speed and feed capabilities.

5. **Thread Depth and Length**: Determine the required thread depth and length. This affects the tool's design, such as the number of flutes and the tool's overall length.

6. **Coolant and Lubrication**: Consider the need for coolant or lubrication. Some tools are designed for dry cutting, while others require coolant to reduce heat and improve finish.

7. **Tool Geometry**: Choose the appropriate tool geometry, including the number of flutes and helix angle, to match the threading operation and material.

8. **Cost and Availability**: Balance cost with quality and availability. High-quality tools may have a higher upfront cost but offer better performance and longevity.

9. **Manufacturer Recommendations**: Consult manufacturer guidelines and recommendations for specific applications and materials.

10. **Trial and Error**: Sometimes, testing different tools in your specific application can help determine the best choice.

What are the common problems with internal threading and how to solve them?

Common problems with internal threading include:

1. **Tool Breakage**: Occurs due to excessive cutting forces or improper tool selection. Solution: Use appropriate tool material and geometry, ensure proper alignment, and apply correct cutting parameters.

2. **Poor Surface Finish**: Results from tool wear, incorrect cutting speed, or improper lubrication. Solution: Use sharp tools, optimize cutting speed, and apply suitable lubricants.

3. **Thread Taper**: Caused by misalignment or machine inaccuracies. Solution: Ensure machine and tool alignment, and regularly calibrate equipment.

4. **Chatter**: Vibration during cutting leads to poor thread quality. Solution: Adjust cutting speed, use dampening techniques, and ensure rigid setup.

5. **Inaccurate Thread Dimensions**: Results from tool wear or incorrect tool path. Solution: Regularly inspect and replace worn tools, and verify tool path accuracy.

6. **Chip Accumulation**: Chips can clog the tool, causing damage. Solution: Use proper chip evacuation techniques, such as coolant or air blast.

7. **Tool Deflection**: Occurs due to excessive cutting forces. Solution: Use shorter tools, reduce cutting forces, and ensure rigid tool holding.

8. **Material Hardness Variations**: Leads to inconsistent threading. Solution: Use consistent material batches and adjust cutting parameters for hardness variations.

9. **Tool Wear**: Causes dimensional inaccuracies and poor finish. Solution: Use high-quality tools and implement regular tool maintenance.

10. **Heat Generation**: Excessive heat can damage the tool and workpiece. Solution: Use appropriate cutting fluids and optimize cutting parameters to reduce heat.

By addressing these issues with proper tool selection, machine setup, and process optimization, internal threading problems can be minimized.

How do you maintain and care for internal threading tools?

To maintain and care for internal threading tools, follow these steps:

1. **Regular Inspection**: Frequently inspect tools for wear, damage, or dullness. Look for signs of chipping or cracking, especially on cutting edges.

2. **Proper Cleaning**: After each use, clean the tools thoroughly to remove metal shavings, dust, and coolant residues. Use a soft brush or compressed air to avoid damaging the tool.

3. **Lubrication**: Apply a light coat of oil to prevent rust and corrosion. Ensure that the oil used is compatible with the tool material.

4. **Sharpening**: Regularly sharpen the cutting edges to maintain efficiency and precision. Use appropriate sharpening tools and techniques specific to the tool material.

5. **Storage**: Store tools in a dry, clean environment. Use protective cases or racks to prevent physical damage and ensure they are not in contact with other tools.

6. **Proper Handling**: Handle tools with care to avoid dropping or knocking them against hard surfaces, which can cause damage.

7. **Correct Usage**: Use the tools within their specified limits. Avoid excessive speeds or feeds that can lead to premature wear or breakage.

8. **Coolant Use**: Ensure proper coolant application during operation to reduce heat and friction, which can extend tool life.

9. **Calibration**: Regularly calibrate tools to ensure accuracy in threading operations. This is crucial for maintaining the quality of the threads produced.

10. **Training**: Ensure that operators are well-trained in the correct use and maintenance of threading tools to prevent misuse and extend tool life.

By following these practices, you can enhance the longevity and performance of internal threading tools, ensuring consistent quality in threading operations.