- Home

- Machining

- Threading

- Taps Internal Threading Tools

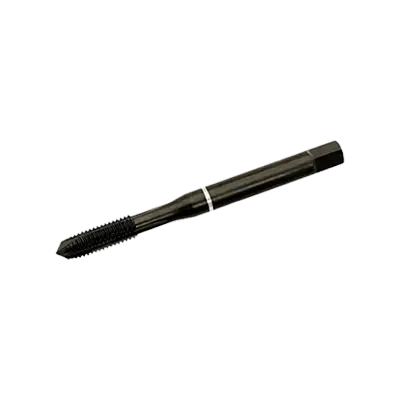

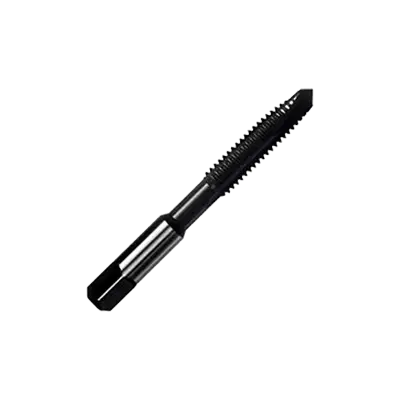

- Spiral Point Taps

.....Read More

General Purpose Spiral-Point Taps

High-Performance Spiral-Point Taps for Aluminum

High-Performance Spiral-Point Taps for Cast Iron

High-Performance Spiral-Point Taps for Multiple Materials

High-Performance Spiral-Point Taps for Nickel & Titanium

High-Performance Spiral-Point Taps for Steel & Stainless Steel

Frequently Asked Questions

What are spiral-point taps used for?

How do spiral-point taps differ from other types of taps?

What materials can spiral-point taps thread?

What is the advantage of using spiral-point taps in through holes?

How do you select the right size spiral-point tap for a job?

What is the difference between general purpose and high-performance spiral-point taps?

How do you maintain and care for spiral-point taps to ensure longevity?