Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

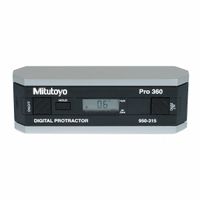

- Precision Measuring Tools

- Protractors Machinist Squares Sets

.....Read More

Frequently Asked Questions

What is the difference between a protractor and an angle finder?

A protractor and an angle finder are both tools used to measure angles, but they differ in design, functionality, and application.

A protractor is a simple, semi-circular or circular tool, typically made of plastic or metal, marked with degrees from 0° to 180° or 0° to 360°. It is primarily used in educational settings for teaching geometry and in drafting for drawing and measuring angles on paper. To use a protractor, you align its baseline with one side of the angle and read the degree measurement where the other side intersects the protractor's scale.

An angle finder, on the other hand, is a more advanced tool used in construction, carpentry, and metalworking. It can be digital or analog and is designed to measure angles more precisely and in various contexts. Digital angle finders often have a digital display for easy reading and can measure angles beyond 180°, making them suitable for complex projects. They may also include features like memory storage, level vials, and the ability to calculate complementary angles. Analog angle finders might resemble a bevel gauge with a pivoting arm and a scale for reading angles.

In summary, while both tools measure angles, a protractor is a basic, manual tool ideal for educational and drafting purposes, whereas an angle finder is a versatile, often digital tool used in professional trades for precise angle measurements in various applications.

How do you use a digital protractor?

To use a digital protractor, first ensure it is powered on and calibrated. Calibration is crucial for accuracy and typically involves placing the protractor on a flat surface and pressing the calibration button to set the zero point.

Next, identify the two surfaces or lines between which you need to measure the angle. Position the digital protractor so that one of its arms or edges aligns with one of these surfaces. The protractor should be stable and not wobble to ensure an accurate reading.

Once aligned, adjust the other arm or edge of the protractor to align with the second surface or line. The digital display will show the angle between the two surfaces. Ensure the protractor remains steady during this process to avoid fluctuations in the reading.

For measuring angles in different orientations, some digital protractors have a hold function. This allows you to lock the reading on the display, making it easier to record the measurement without needing to keep the protractor in place.

If the protractor has additional features like a backlight or a rotating display, use these to enhance visibility and readability in various lighting conditions or awkward positions.

After use, turn off the digital protractor to conserve battery life. Store it in a protective case if available to prevent damage. Regularly check and replace the batteries as needed to ensure consistent performance.

What are the benefits of using a digital angle finder over a manual one?

A digital angle finder offers several advantages over a manual one, enhancing precision, efficiency, and ease of use. Firstly, digital angle finders provide highly accurate readings, often to a tenth of a degree, reducing human error associated with manual readings. This precision is crucial in fields like carpentry, metalworking, and construction, where exact angles are necessary for quality results.

Secondly, digital angle finders are user-friendly, featuring clear digital displays that are easy to read, even in low-light conditions. This contrasts with manual angle finders, which require careful interpretation of scales and can be difficult to read accurately. The digital display often includes backlighting, further aiding visibility.

Another benefit is the ability to store and recall measurements. Many digital models have memory functions that allow users to save multiple angle readings, facilitating complex projects that require repeated measurements. This feature is absent in manual angle finders, which rely on the user’s memory or external recording.

Digital angle finders often come with additional features such as the ability to calculate relative angles, hold functions to freeze measurements, and even Bluetooth connectivity for data transfer to other devices. These features enhance versatility and integration with digital workflows, streamlining processes and improving productivity.

Moreover, digital angle finders are generally faster to use. They provide instant readings, eliminating the need for manual adjustments and calculations. This speed is beneficial in time-sensitive projects, allowing for quicker decision-making and execution.

Finally, digital angle finders are often more durable and robust, designed to withstand harsh working environments. They are typically constructed with materials that resist wear and tear, ensuring longevity and consistent performance over time.

In summary, digital angle finders offer superior accuracy, ease of use, additional functionalities, and durability, making them a valuable tool for professionals and hobbyists alike.

How accurate are digital protractors?

Digital protractors are generally quite accurate, often providing measurements with a precision of up to 0.1 degrees. The accuracy of a digital protractor depends on several factors, including the quality of the device, the calibration, and the conditions under which it is used. High-quality digital protractors from reputable manufacturers are designed to offer reliable and consistent measurements, often featuring advanced sensors and calibration mechanisms to ensure precision.

The accuracy can be affected by external factors such as temperature, humidity, and the surface on which the protractor is used. For instance, using a digital protractor on an uneven or unstable surface can lead to measurement errors. Additionally, the device's calibration is crucial; regular calibration checks are recommended to maintain accuracy over time.

Digital protractors often come with features like zero-setting functions, which allow users to set a reference point for more accurate relative measurements. Some models also include backlit displays and hold functions to improve usability in various conditions.

In professional settings, digital protractors are preferred for their ease of use and quick readouts, which reduce human error compared to traditional protractors. However, for critical applications requiring extremely high precision, such as in certain engineering or scientific fields, it may be necessary to verify the digital protractor's readings with other precision instruments.

Overall, while digital protractors are highly accurate for most practical applications, users should be aware of their limitations and ensure proper usage and maintenance to achieve the best results.

Can a protractor measure angles greater than 180 degrees?

No, a standard protractor cannot measure angles greater than 180 degrees directly. A typical protractor is a semicircular tool marked from 0 to 180 degrees, designed to measure angles within this range. To measure angles greater than 180 degrees, one can use a full-circle protractor, which is marked from 0 to 360 degrees, or measure the supplementary angle (the angle that, when added to the given angle, equals 360 degrees) using a standard protractor and then subtract from 360 degrees to find the original angle.

What is a bevel protractor used for?

A bevel protractor is a precision instrument used for measuring angles. It is commonly employed in fields such as metalworking, carpentry, and engineering to ensure accuracy in the creation and assembly of components. The tool consists of a graduated circular scale, a movable arm, and a vernier scale for enhanced precision.

The primary function of a bevel protractor is to measure angles between two surfaces. It can measure both acute and obtuse angles, typically ranging from 0 to 180 degrees, although some models can measure up to 360 degrees. The protractor's design allows it to be used in various applications, such as setting the angle of a workpiece, checking the angle of a cut, or transferring an angle from one part to another.

The bevel protractor is particularly useful in situations where high precision is required. The vernier scale, which is a secondary scale that allows for more precise readings, can measure angles to a fraction of a degree, often to the nearest minute (1/60th of a degree). This level of precision is crucial in tasks like machining, where even small deviations can lead to significant errors in the final product.

In addition to measuring angles, a bevel protractor can also be used to mark angles on a workpiece. By setting the protractor to the desired angle and using the arm as a guide, users can draw lines or make cuts with high accuracy. This versatility makes the bevel protractor an essential tool in any workshop or manufacturing environment where precision is paramount.

How do you calibrate a digital angle finder?

To calibrate a digital angle finder, follow these steps:

1. **Preparation**: Ensure the digital angle finder is clean and free from dust or debris. Check the battery level to ensure it is fully charged or replace it if necessary.

2. **Zero Calibration**: Place the angle finder on a flat, level surface. Turn it on and press the "zero" or "calibrate" button to set the baseline measurement. This step ensures that the device reads 0 degrees on a perfectly flat surface.

3. **Verification**: To verify the zero calibration, rotate the angle finder 180 degrees on the same surface. It should still read 0 degrees. If not, repeat the zero calibration process.

4. **90-Degree Calibration**: To check the 90-degree accuracy, place the angle finder against a known 90-degree angle, such as a carpenter's square or a verified right angle. The device should read 90 degrees. If it does not, consult the user manual for specific calibration adjustments.

5. **180-Degree Calibration**: For further accuracy, place the angle finder on a surface with a known 180-degree angle. It should read 180 degrees. If discrepancies are found, recalibrate or consult the manual for adjustments.

6. **Cross-Verification**: Use the angle finder on various known angles to ensure consistent readings. Compare these readings with a reliable protractor or another calibrated angle finder.

7. **Recalibration**: If the device consistently shows incorrect readings, recalibrate it according to the manufacturer's instructions. Some models may have a reset or recalibration function accessible through the settings menu.

8. **Regular Checks**: Regularly check and recalibrate the angle finder to maintain accuracy, especially before critical measurements.

By following these steps, you ensure that your digital angle finder provides accurate and reliable measurements.