Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

- Precision Measuring Tools

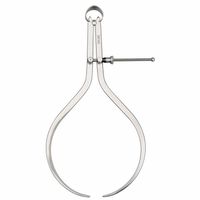

- Calipers Accessories

.....Read More

Frequently Asked Questions

What is the difference between Vernier, dial, and digital calipers?

Vernier calipers, dial calipers, and digital calipers are precision measuring tools used to measure dimensions with high accuracy, but they differ in their mechanisms and ease of use.

Vernier calipers consist of a main scale and a sliding Vernier scale. The user reads measurements by aligning the scales, which requires skill and practice. They are durable, do not require batteries, and are cost-effective. However, they can be challenging to read, especially for those unfamiliar with the Vernier scale.

Dial calipers feature a dial indicator that displays measurements. The main scale provides the primary measurement, while the dial shows the fractional part. They are easier to read than Vernier calipers and offer quick measurements. However, they are more delicate due to the mechanical dial and can be affected by dust and debris. They also do not require batteries.

Digital calipers display measurements on an electronic screen, making them the easiest to read. They offer quick and accurate readings, often with the ability to switch between metric and imperial units. Digital calipers require batteries and can be more expensive. They are sensitive to moisture and extreme temperatures, which can affect their accuracy.

In summary, Vernier calipers are durable and cost-effective but require skill to read. Dial calipers are easier to read but more delicate. Digital calipers offer the easiest and most versatile reading but require batteries and are sensitive to environmental conditions.

How do you read a Vernier caliper?

To read a Vernier caliper, follow these steps:

1. **Zero the Caliper**: Before measuring, ensure the caliper is zeroed. Close the jaws completely and check that the zero on the main scale aligns with the zero on the Vernier scale. If not, adjust accordingly.

2. **Place the Object**: Open the jaws and place the object between them. For internal measurements, use the smaller jaws; for external measurements, use the larger ones. For depth measurements, use the depth rod.

3. **Read the Main Scale**: Look at the main scale (fixed scale) and note the last whole number before the zero of the Vernier scale. This gives you the main scale reading in millimeters or inches.

4. **Read the Vernier Scale**: Observe the Vernier scale (sliding scale) and find the line that aligns exactly with any line on the main scale. The number on the Vernier scale that aligns is the Vernier reading.

5. **Calculate the Measurement**: Add the main scale reading to the Vernier scale reading. The Vernier scale reading is typically in smaller increments (e.g., 0.02 mm or 0.001 inches), so multiply it by the least count of the Vernier scale before adding.

6. **Example**: If the main scale reads 5 mm and the 3rd line on the Vernier scale aligns, and the least count is 0.02 mm, the Vernier reading is 3 x 0.02 = 0.06 mm. Total measurement = 5 mm + 0.06 mm = 5.06 mm.

7. **Record the Measurement**: Note down the measurement, ensuring to include the unit of measurement.

By following these steps, you can accurately read a Vernier caliper and obtain precise measurements.

What are the advantages of digital calipers over dial calipers?

Digital calipers offer several advantages over dial calipers:

1. **Ease of Reading**: Digital calipers display measurements on an LCD screen, eliminating the need to interpret a dial. This reduces the chance of human error and makes it easier to read measurements quickly and accurately.

2. **Metric and Imperial Conversion**: Digital calipers can easily switch between metric and imperial units with the push of a button, providing flexibility and convenience for users who work with both measurement systems.

3. **Zero Setting**: Digital calipers allow users to set zero at any point, enabling differential measurements. This feature is particularly useful for comparing dimensions or measuring incremental changes.

4. **Data Output**: Many digital calipers come with data output capabilities, allowing them to connect to computers or other devices for data logging and analysis. This is beneficial for quality control and documentation purposes.

5. **Precision and Accuracy**: Digital calipers generally offer higher precision and accuracy compared to dial calipers, often providing measurements to 0.01 mm or 0.0005 inches.

6. **Ease of Use**: The digital display simplifies the measurement process, making digital calipers more user-friendly, especially for those who may not be familiar with reading dial calipers.

7. **No Parallax Error**: Digital calipers eliminate parallax error, which can occur with dial calipers when the needle is viewed from an angle.

8. **Durability**: Many digital calipers are designed to be more resistant to dust and water, enhancing their durability and reliability in various working environments.

9. **Advanced Features**: Some digital calipers offer additional features such as automatic shut-off to conserve battery life, and some models include Bluetooth connectivity for wireless data transfer.

Overall, digital calipers provide enhanced functionality, ease of use, and accuracy, making them a preferred choice for many users in precision measurement tasks.

How do you maintain and care for calipers?

To maintain and care for calipers, follow these steps:

1. **Cleaning**: Regularly clean the calipers with a soft, lint-free cloth to remove dust and debris. For stubborn dirt, use a mild soap solution and ensure the calipers are completely dry afterward. Avoid using harsh chemicals or solvents that can damage the surfaces.

2. **Lubrication**: Apply a light machine oil or a specialized caliper lubricant to the sliding surfaces and moving parts to ensure smooth operation. Wipe off any excess oil to prevent attracting dust.

3. **Storage**: Store calipers in a protective case or pouch when not in use to prevent damage. Keep them in a dry, cool environment to avoid rust and corrosion. Avoid placing heavy objects on top of them.

4. **Handling**: Handle calipers with care. Avoid dropping or applying excessive force, which can misalign or damage the measuring jaws. Always use the thumb wheel or fine adjustment screw for precise measurements.

5. **Calibration**: Regularly check the calibration of your calipers against a known standard. If they are out of calibration, adjust them according to the manufacturer's instructions or have them professionally calibrated.

6. **Inspection**: Periodically inspect the calipers for signs of wear, damage, or misalignment. Check the jaws for nicks or burrs and ensure the digital display (if applicable) is functioning correctly.

7. **Battery Care**: For digital calipers, replace the battery as needed. Remove the battery if the calipers will not be used for an extended period to prevent leakage.

By following these maintenance steps, you can ensure the longevity and accuracy of your calipers, making them a reliable tool for precise measurements.

What are the common uses of calipers in various industries?

Calipers are versatile measuring tools used across various industries for precise measurements. In the manufacturing sector, they are essential for quality control, ensuring components meet specified dimensions. Machinists use calipers to measure the thickness, diameter, and depth of parts, crucial for maintaining tolerances in metalworking and fabrication.

In the automotive industry, calipers are employed to measure brake disc thickness, ensuring safety and performance. They are also used in engine assembly to verify the dimensions of pistons, cylinders, and other critical components.

In the aerospace industry, calipers are vital for measuring the dimensions of aircraft parts, where precision is crucial for safety and performance. They help in maintaining the stringent tolerances required for components like turbine blades and fuselage parts.

In the medical field, calipers are used in orthopedics to measure bone dimensions and in prosthetics to ensure the proper fit of artificial limbs. They are also used in dentistry to measure teeth and dental appliances.

In the woodworking industry, calipers help in measuring the thickness of wood and the dimensions of joints, ensuring precision in furniture making and carpentry.

In the electronics industry, calipers are used to measure the dimensions of circuit boards and components, ensuring they fit correctly in devices.

In the jewelry industry, calipers are used to measure gemstones and metal pieces, ensuring precision in design and assembly.

Overall, calipers are indispensable tools in any industry where precision measurement is critical, contributing to quality assurance, safety, and efficiency.

How do you calibrate a digital caliper?

1. **Clean the Caliper**: Ensure the caliper is free from dust, dirt, and oil. Use a soft cloth to clean the jaws and the beam.

2. **Zero the Caliper**: Close the jaws completely and press the zero button to set the display to 0.000 mm or 0.000 inches. This ensures the caliper starts from a true zero point.

3. **Check for Zero Error**: Open and close the jaws several times to ensure the display returns to zero each time. If it doesn’t, recalibrate by pressing the zero button again.

4. **Use a Calibration Block**: Obtain a certified gauge block or calibration standard with a known measurement. Place it between the jaws of the caliper.

5. **Measure the Calibration Block**: Close the jaws gently on the block without applying excessive force. Note the reading on the display.

6. **Compare and Adjust**: Compare the caliper reading with the known measurement of the calibration block. If there is a discrepancy, adjust the caliper according to the manufacturer’s instructions, if possible.

7. **Repeat the Process**: Test the caliper at various points along its range using different gauge blocks to ensure accuracy across its entire measuring span.

8. **Check for Consistency**: Open and close the jaws multiple times at each calibration point to ensure consistent readings.

9. **Document the Calibration**: Record the results of the calibration process, including any adjustments made, for future reference and compliance with quality standards.

10. **Regular Calibration**: Establish a regular calibration schedule based on usage frequency and precision requirements to maintain accuracy over time.

What is the IP rating for harsh-environment digital calipers?

The IP rating for harsh-environment digital calipers is typically IP67.